Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In a world where culinary trends evolve at a rapid pace, the sandwich press has emerged as a must-have kitchen gadget. Its versatility and the convenience it offers in achieving that perfect grill mark on a sandwich or a juicy burger patty have made it a staple in homes and restaurants alike. As the demand for high-quality sandwich presses continues to soar, we delve into the revolution of dual voltage models, exploring their benefits, challenges, and the role of OEMs in shaping this dynamic market. This exploration aims to illuminate the path forward for the sandwich press industry and the innovations that are poised to redefine it.

The sandwich press market has seen a significant surge in popularity over the past few years, with dual voltage models leading the charge. This phenomenon is driven by several factors that have created a perfect storm for the growth of 120V/240V dual voltage sandwich presses.

Consumers are increasingly seeking versatility and convenience in their kitchen appliances, and the dual voltage sandwich press checks both boxes. These innovative machines can operate in regions where the standard voltage is either 120V or 240V, making them an attractive choice for global travelers and expats who want to recreate the same culinary experiences in different countries.

One of the primary reasons for the rise in popularity is the globalization of culinary trends. As international food cultures blend together, the demand for a variety of dishes has expanded. The dual voltage sandwich press allows home chefs to make everything from classic American grilled cheese sandwiches to gourmet Japanese okonomiyaki without the need for additional adaptors or voltage converters.

Moreover, the technological advancements in sandwich press design have not gone unnoticed. Modern models are sleeker, more user-friendly, and often come with additional features such as adjustable temperature controls, non-stick surfaces, and digital displays. These improvements have made sandwich presses not just a tool for making a quick meal, but a statement piece on kitchen countertops.

Another factor contributing to the surge in dual voltage sandwich presses is the emphasis on healthy eating. As people look for ways to prepare meals at home that are both nutritious and delicious, the sandwich press offers a solution. It allows for the cooking of lean proteins and fresh vegetables, while the natural steam released by the sandwich press helps to lock in the food’s flavors and vitamins.

OEMs (Original Equipment Manufacturers) have been instrumental in driving this trend forward. By producing high-quality sandwich presses that cater to the global market’s diverse needs, OEMs are able to supply retailers with products that are both efficient and compliant with international standards. The ability to offer a dual voltage option means that OEMs can tap into a broader customer base, as these presses are no longer limited to markets that use a single voltage standard.

In addition to the market expansion, the environmental impact of dual voltage appliances cannot be overlooked. By designing products that can operate in different voltage ranges, OEMs are reducing the need for energy-wasting converters and adaptors, which ultimately contributes to a lower carbon footprint.

As the sandwich press market continues to grow, so too does the competition. Manufacturers are pushing the boundaries of what a sandwich press can do, introducing models that are not only versatile but also energy-efficient. The integration of smart technology is becoming more common, with some presses now capable of being controlled via smartphone apps, further enhancing the user experience.

The rise of dual voltage sandwich presses also reflects a shift in consumer behavior. People are no longer satisfied with generic, one-size-fits-all products. They want appliances that can adapt to their specific needs and preferences, and dual voltage models offer just that.

Furthermore, the availability of online shopping and cross-border e-commerce has made it easier than ever for consumers to purchase dual voltage appliances. With just a few clicks, customers can now have a high-quality sandwich press delivered to their doorstep, regardless of their location.

In conclusion, the rise of dual voltage sandwich presses is a testament to the evolving culinary landscape and the consumer’s quest for convenience, health, and quality. As OEMs continue to innovate and meet these demands, the future of the sandwich press market looks bright and varied.

The 120V/240V dual voltage feature in sandwich presses is a game-changer for both consumers and manufacturers. This versatile capability allows these appliances to operate seamlessly across various countries with different electrical standards. Let’s delve into what this dual voltage feature entails and why it’s so significant in today’s market.

The concept of dual voltage is quite straightforward. Essentially, it means that the sandwich press is designed to work with two different electrical voltage systems: 120V and 240V. This adaptability is crucial because many countries around the world use one of these two voltage standards, with the United States and Canada predominantly using 120V, while most of Europe and Asia operate on a 240V system.

The significance of dual voltage in sandwich presses cannot be overstated. For consumers, it means that they can purchase a single appliance and use it without worrying about compatibility issues when they travel or move to a different country. This is particularly convenient for those living in dual-voltage households or for those who frequently travel internationally, as it eliminates the need for separate appliances for different voltage systems.

From a manufacturing perspective, offering a dual voltage sandwich press opens up a broader market. OEMs (Original Equipment Manufacturers) can cater to a global audience without the need to produce multiple versions of the same product for different regions. This streamlines production, reduces costs, and simplifies inventory management.

One of the key advantages of dual voltage sandwich presses is their ability to maintain consistent performance across different voltage levels. This is achieved through the use of transformers or voltage regulators within the appliance. These components ensure that the electrical current remains stable, regardless of whether the press is operating at 120V or 240V.

Understanding how this dual voltage feature works is essential. When a sandwich press is designed for dual voltage, the internal components are carefully engineered to handle both voltage levels. This includes the motor, heating elements, and any electronic controls. In some cases, the design may also incorporate safety features to prevent damage from overvoltage or undervoltage conditions.

In terms of energy efficiency, dual voltage sandwich presses can be more advantageous. Since the appliance is designed to work with both lower and higher voltage systems, it can optimize its energy consumption based on the available voltage. This means that in regions where electricity is more expensive, the appliance can still operate efficiently, potentially saving consumers money on their energy bills.

Another aspect to consider is the physical design of dual voltage sandwich presses. The appliance may have a slightly larger footprint or different wiring configurations to accommodate both voltage systems. However, these differences are often negligible, and the overall look and feel of the product remain consistent.

Despite the many benefits, there are some challenges associated with dual voltage sandwich presses. For instance, the design complexity can lead to higher production costs. Additionally, ensuring that the appliance meets safety standards in both voltage systems can be a complex process.

In the realm of innovation, some manufacturers are pushing the boundaries of dual voltage technology. They are exploring ways to make these presses even more energy-efficient and user-friendly. For example, some models now come with automatic voltage detection, which allows the appliance to switch between 120V and 240V without any manual intervention.

In conclusion, the 120V/240V dual voltage feature in sandwich presses is a testament to the evolving landscape of appliance design. It not only provides convenience and cost savings to consumers but also offers manufacturers a competitive edge in the global market. As technology continues to advance, we can expect to see even more sophisticated dual voltage solutions that enhance the functionality and reliability of these popular kitchen gadgets.

The sandwich press market has seen a surge in popularity, and it’s not just a fleeting trend. Several factors contribute to this booming industry, making it a hotbed for innovation and consumer interest.

People are increasingly seeking convenience in their daily lives, and the sandwich press fits perfectly into this lifestyle. Busy schedules, the desire for homemade meals, and the preference for healthier eating habits have all played a role in the rise of this market. With the sandwich press, you can create a fresh, custom-tailored meal in minutes, without the need for complex cooking skills or time-consuming preparation.

Moreover, the versatility of the sandwich press is undeniable. It’s not just for sandwiches anymore. Home chefs are experimenting with a variety of recipes, from gourmet melts to savory flatbreads, using these handy appliances. This flexibility has opened up a world of possibilities for users, making the sandwich press a staple in many kitchens.

The trend towards home cooking and baking has also fueled the growth of the sandwich press market. As people spend more time at home, they’re looking for ways to enjoy the process of cooking and baking, not just the end result. Sandwich presses offer a fun, interactive way to engage with food preparation, making them a favorite among both beginners and seasoned cooks.

Another key driver is the health-conscious consumer. With the growing awareness of the importance of a balanced diet, people are turning to homemade meals to control their intake of unhealthy fats, sugars, and preservatives. The sandwich press allows for fresh ingredients and portion control, aligning with these health-focused eating habits.

Social media has also played a significant role in the sandwich press market’s boom. Influencers and chefs often showcase their culinary creations using sandwich presses, creating a sense of excitement and desire among their followers. These social media mentions can quickly turn into buzz, driving sales and curiosity about the products.

In addition, the convenience of portable sandwich presses has caught the attention of those with active lifestyles. Hikers, campers, and office workers are all embracing the idea of having a sandwich press on hand for a quick, warm meal. This portability has expanded the market beyond traditional home use, reaching a broader audience.

The affordability of sandwich presses is another factor contributing to their popularity. With a wide range of prices to suit different budgets, these appliances have become accessible to a large segment of the population. This affordability has allowed more people to experience the joy of homemade sandwiches, further fueling the market’s growth.

Lastly, the environmental movement has had a ripple effect on the sandwich press market. As people become more conscious of reducing their carbon footprint, they’re seeking out reusable and durable kitchen gadgets. Sandwich presses are often made from stainless steel or non-stick materials, making them a sustainable choice for eco-conscious consumers.

In conclusion, the sandwich press market is booming due to a combination of convenience, versatility, health trends, social media influence, portability, affordability, and environmental awareness. These factors have created a perfect storm, making the sandwich press an indispensable kitchen tool for many.

In recent years, the sandwich press market has seen a surge in popularity, and it’s not hard to see why. These versatile kitchen gadgets have evolved beyond the simple grill, now offering a myriad of features and designs that cater to both casual home chefs and professional cooks. Let’s delve into some of the innovative aspects that have propelled the sandwich press market to new heights.

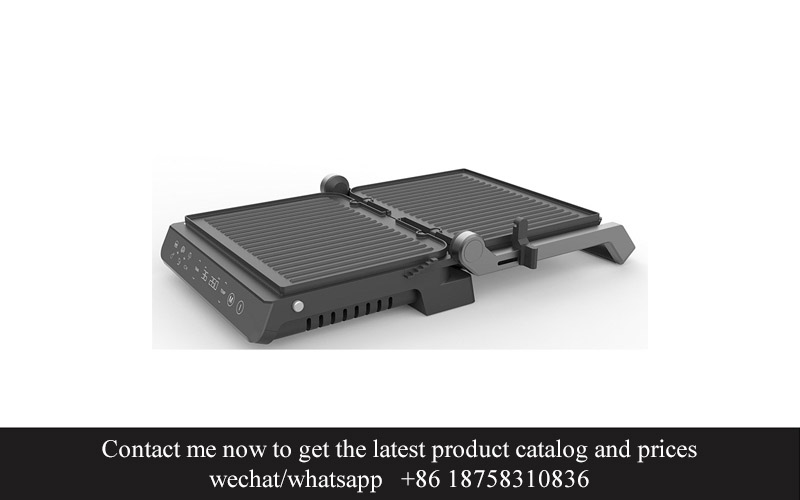

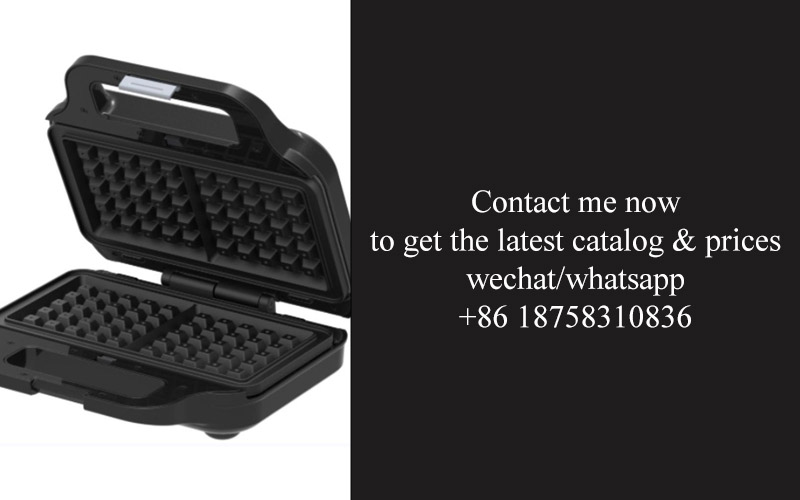

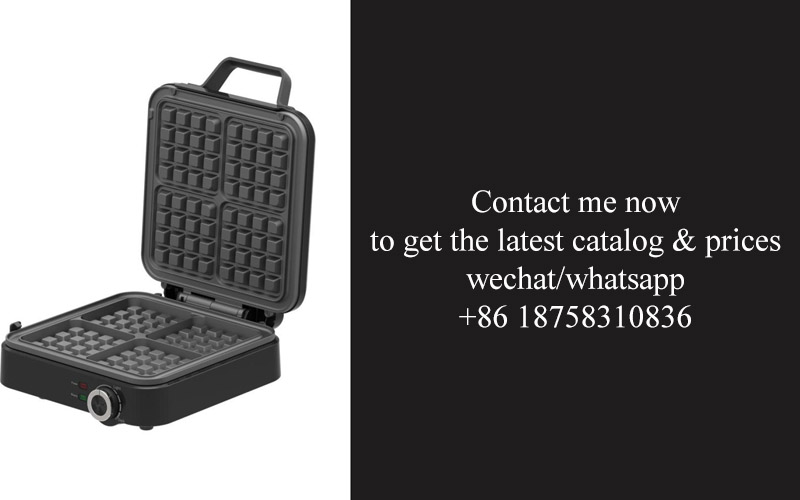

Enhanced Cooking Surface TechnologyOne of the standout innovations in sandwich press design is the evolution of the cooking surface. Traditional presses often used a flat surface, but modern designs have introduced textured surfaces that mimic the effects of grilling, searing, or even adding a crispy texture to the bread. These surfaces are often non-stick and made from high-quality materials like cast iron or stainless steel, ensuring even heat distribution and longevity.

Smart Temperature ControlModern sandwich presses come with advanced temperature control systems that allow users to precisely set the cooking temperature. This feature is particularly beneficial for those who like to experiment with different types of bread and fillings, as it ensures that each sandwich is cooked to perfection. Some models even have digital displays that provide real-time feedback on the temperature, making it easy to monitor the cooking process.

Variable Pressing MechanismsThe pressing mechanism is a crucial aspect of any sandwich press. Innovations in this area include adjustable pressure settings that cater to different bread types and thicknesses. For instance, a lighter pressure might be ideal for delicate ciabatta or baguettes, while a firm press is perfect for thick, hearty loaves like rye or sourdough. This flexibility allows users to achieve the desired texture and crispiness in their sandwiches.

Integrated Grilling ElementsFor those who want to take their sandwich-making to the next level, some presses now come with integrated grilling elements. These features allow users to not only toast the bread but also to achieve a grill mark on the surface, adding a smoky, charred flavor that elevates the sandwich experience. The ability to grill and toast simultaneously is a game-changer for those looking for a gourmet sandwich at home.

Versatility in FunctionalitySandwich presses are no longer just for making sandwiches. Many innovative models now offer additional functionalities, such as the ability to make paninis, press burgers, or even act as a grill for vegetables and proteins. The versatility of these appliances has expanded their appeal, making them a must-have for anyone interested in quick and easy meals.

Design and AestheticsThe design of sandwich presses has also seen a significant evolution. Modern models are sleeker, with ergonomic handles and stylish finishes that complement any kitchen decor. Some brands have even started to incorporate smart features, like Bluetooth connectivity, allowing users to control their sandwich press remotely via a smartphone app.

Safety and ConvenienceSafety and convenience are at the forefront of new sandwich press designs. Features like automatic shut-off after a certain period or when the cooking surface reaches a safe temperature prevent overcooking and potential burns. Additionally, many presses are now designed with easy-to-clean surfaces and removable parts, making maintenance a breeze.

Customizable Pressing PlatesFor those who like to personalize their cooking experience, some sandwich presses offer customizable pressing plates. These plates can be swapped out for different shapes and sizes, allowing users to create unique and visually appealing sandwiches. This innovation caters to the growing trend of Instagram-worthy meals and at-home culinary adventures.

Eco-friendly and Sustainable MaterialsAs awareness of environmental issues grows, sandwich press manufacturers are increasingly using sustainable and eco-friendly materials. This includes recycled plastics for non-stick coatings and biodegradable components for parts that come into contact with food. These eco-conscious designs appeal to environmentally conscious consumers.

Smart Cooking ProgramsFinally, some high-end sandwich presses come with smart cooking programs that can be programmed for different types of sandwiches. Users can set their preferred cooking time and temperature, and the press will automatically adjust to ensure the perfect outcome every time. This level of convenience and precision is a testament to the ongoing innovation in sandwich press design.

In summary, the sandwich press market is booming due to the continuous innovation in design, functionality, and user experience. These advancements have transformed the humble sandwich press into a versatile kitchen tool that can cater to a wide range of culinary preferences and needs.

In the world of sandwich presses, Original Equipment Manufacturers (OEMs) play a pivotal role in shaping the industry. These companies are not just producers of hardware; they are the architects of innovation, the enablers of customization, and the guardians of quality. Here’s how OEMs are making their mark in the sandwich press industry:

OEMs are the backbone of the sandwich press industry, offering manufacturers the flexibility to tailor their products to meet specific market demands. By designing and producing customized presses, they allow for a diverse range of functionalities and features, ensuring that each brand can stand out in a crowded marketplace.

They are at the forefront of technological advancements, incorporating new materials, such as non-stick coatings, which not only improve user experience but also enhance the longevity of the sandwich press. These innovations are crucial for brands looking to offer the latest in kitchen technology to consumers.

OEMs often collaborate closely with foodservice professionals, gaining insights into the needs of commercial kitchens. This partnership leads to the development of heavy-duty sandwich presses that can withstand high usage rates, making them ideal for busy restaurants, cafes, and food trucks.

One of the key advantages of working with an OEM is the ability to source parts and components from a single supplier. This integration of the supply chain reduces lead times and costs, as well as ensures consistency in the quality of the final product. For brands, this means a streamlined process from design to delivery.

The role of OEMs in the sandwich press industry is also evident in their commitment to sustainability. Many OEMs are now using eco-friendly materials and practices, not only to appeal to environmentally conscious consumers but also to minimize the environmental impact of their products throughout their lifecycle.

Customization extends beyond the product itself. OEMs can offer brands the chance to brand their sandwich presses with their logos and colors, creating a unique selling proposition. This level of personalization can significantly enhance brand recognition and loyalty.

Innovation isn’t just about the physical design of the sandwich press. OEMs are also responsible for creating software and user interfaces that make these devices easier to use and maintain. From intuitive control panels to programmable settings, the software side of OEMs’ offerings adds value and convenience.

OEMs also understand the importance of service and support. They often provide comprehensive training and maintenance programs for both the end-users and the resellers. This ensures that the sandwich presses remain operational and reliable, even in harsh commercial environments.

As the demand for high-quality, efficient sandwich presses grows, OEMs are stepping up their game. They’re investing in research and development to create presses that are not only powerful but also user-friendly, quiet, and space-saving. These advancements cater to both home users and commercial establishments.

In the sandwich press industry, OEMs are the silent architects of success. They provide the tools that manufacturers need to innovate, adapt, and excel in a competitive market. From the design and production of the presses to the branding and customer support, OEMs are instrumental in driving the industry forward.

Their strategic partnerships with global brands allow for the creation of unique product lines that can be distributed across various markets. This international reach is crucial for companies looking to expand their customer base and increase their market share.

OEMs are also at the forefront of regulatory compliance, ensuring that their sandwich presses meet the safety standards and certifications required by different regions. This not only protects consumers but also helps manufacturers avoid costly legal issues.

The role of OEMs in the sandwich press industry is multifaceted. They are the innovators, the problem solvers, and the collaborators. As the industry continues to evolve, it’s the OEMs who are driving the narrative, bringing new ideas and solutions to the table that resonate with consumers and businesses alike.

In the ever-evolving landscape of kitchen appliances, the 120V/240V sandwich press has emerged as a versatile and sought-after product. As we delve into the global market, it becomes clear that these dual-voltage sandwich presses are not just a trend but a necessity for various regions around the world. Here’s a closer look at what makes them so pivotal in the international marketplace.

The adaptability of 120V/240V sandwich presses is a game-changer. These appliances can seamlessly transition between the two voltage standards, making them ideal for travelers, expatriates, and anyone who moves frequently. This dual capability ensures that regardless of the country’s electrical infrastructure, users can enjoy the convenience of a high-quality sandwich press.

The global market is vast and diverse, with each region having its unique preferences and needs. For instance, in North America, where 120V is the standard, the 120V/240V sandwich press is a must-have for those who might need to use it in countries with 240V systems. Conversely, in Europe and Asia, where 240V is more common, the 120V/240V sandwich press serves as a reliable companion for international travelers.

The demand for these dual-voltage models is also driven by the rise of health-conscious consumers. As the world becomes more health-aware, the popularity of home cooking has surged. Sandwich presses offer a quick and easy way to prepare nutritious and delicious meals, which is why they have become a staple in many households across the globe.

In the global market, the 120V/240V sandwich press is not just a kitchen gadget; it’s a symbol of convenience and adaptability. It appeals to a wide range of customers, from busy professionals looking to prepare a quick lunch to families seeking a fun and interactive way to make meals together.

Moreover, the global market for sandwich presses is influenced by the increasing trend of cross-cultural culinary exploration. As people become more open to trying new flavors and techniques, the sandwich press has become a versatile tool for creating a variety of international sandwiches, from classic American grilled cheese to gourmet Japanese-style bento boxes.

In terms of distribution, the global market for 120V/240V sandwich presses is complex, with various channels catering to different customer segments. Online retailers play a significant role, offering a wide selection of brands and models, often with the added convenience of international shipping. Local department stores and specialty kitchenware shops also contribute to the market, providing customers with the opportunity to see and try products before purchasing.

The marketing strategies for 120V/240V sandwich presses in the global market often emphasize the product’s versatility and ease of use. Manufacturers and retailers highlight the fact that these presses can be used anywhere in the world, making them a perfect gift for friends and family living abroad or for those planning to travel.

In conclusion, the global market for 120V/240V sandwich presses is thriving due to their adaptability, health benefits, and the growing interest in international cuisine. As the world becomes more interconnected, these dual-voltage appliances are poised to continue their rise, becoming a staple in kitchens worldwide.

In the ever-evolving world of kitchen appliances, dual voltage sandwich presses have emerged as a versatile and convenient option for both commercial and domestic use. These innovative devices offer a range of benefits, but they also come with their set of challenges. Let’s delve into what makes these presses a hit in the market and what hurdles they face.

One of the most significant benefits of dual voltage sandwich presses is their adaptability. With the ability to operate on both 120V and 240V power supplies, these presses can be used almost anywhere in the world. This feature is particularly appealing to businesses that operate internationally or those looking to expand their market reach. The convenience of a single appliance that can handle different power standards is invaluable, as it eliminates the need for transformers or voltage converters, saving both time and money.

Another advantage is the even heat distribution that these presses provide. The dual voltage capability allows for precise temperature control, ensuring that the sandwiches are cooked to perfection every time. This consistency is crucial for commercial establishments that rely on speed and quality to maintain customer satisfaction. The even cooking also extends the life of the bread, reducing waste and improving the overall cost-effectiveness of the operation.

Users of dual voltage sandwich presses often praise their durability. High-quality materials and robust construction ensure that these appliances can withstand the rigors of daily use in busy kitchens. The robust build is a testament to the longevity of these presses, making them a wise investment for any business. Moreover, the fact that they can handle both low and high voltage systems without compromising performance speaks to their reliability.

Despite their many benefits, dual voltage sandwich presses are not without their challenges. One of the most prominent challenges is the complexity of the design. Incorporating the ability to switch between two voltage systems requires intricate engineering and precise components. This complexity can lead to higher production costs, which might be passed on to the consumer. However, as technology advances and production scales up, these costs are likely to decrease.

Another challenge lies in the regulatory landscape. Different countries have varying standards and certifications for electrical appliances. Ensuring that a dual voltage sandwich press complies with all relevant regulations can be a daunting task for manufacturers. It requires a deep understanding of international electrical codes and a commitment to quality control throughout the production process.

In the market, dual voltage sandwich presses face competition from single-voltage models, which are often more affordable. While these models may lack the versatility of dual voltage presses, they can still meet the needs of certain customers, particularly those in regions where voltage standards are consistent. This competition drives innovation, as manufacturers strive to offer features and benefits that differentiate their products.

On the consumer front, the learning curve can be steep for those unfamiliar with the dual voltage feature. Understanding how to safely switch between voltage settings and maintain the appliance can be a barrier for some users. However, as awareness grows and more people become accustomed to the technology, this challenge is likely to diminish.

The market for dual voltage sandwich presses is also influenced by consumer trends. For instance, there is a growing demand for healthier eating options, and these presses can be used to create a variety of nutritious sandwiches. As more people seek to control their diet, the versatility of these presses becomes even more appealing.

Lastly, the sustainability aspect cannot be overlooked. Dual voltage presses are more energy-efficient than single-voltage models in certain scenarios, as they can be operated at the optimal voltage for the local power supply. This not only reduces energy consumption but also has a positive environmental impact.

In summary, the benefits of dual voltage sandwich presses, such as adaptability, even heat distribution, durability, and energy efficiency, make them a compelling choice for many users. However, the challenges of design complexity, regulatory compliance, competition, and consumer education must be addressed for these presses to reach their full potential in the global market. As the industry continues to evolve, it will be fascinating to see how manufacturers navigate these challenges and capitalize on the opportunities presented by dual voltage technology.

In the realm of sandwich presses, Original Equipment Manufacturers (OEMs) play a pivotal role, shaping the landscape of the industry with their strategic partnerships and innovative solutions. Here are a few notable case studies showcasing successful OEM collaborations that have left a mark in the market.

A. The Fusion of Design and FunctionalityOne such partnership involved a well-known sandwich press OEM teaming up with a leading kitchen appliance company. Together, they developed a sleek, compact sandwich press that combined the latest design trends with user-friendly features. The result was a product that not only looked modern but also offered superior functionality, appealing to both culinary enthusiasts and casual home cooks alike.

B. Market Expansion through CustomizationAn OEM worked closely with an international brand to tailor a sandwich press that catered to specific regional preferences. By understanding the diverse tastes and cooking habits across different markets, the OEM was able to customize the press to include additional settings and features that would resonate with global consumers. This partnership led to a significant expansion of the brand’s product line and a boost in sales in various countries.

C. Technology Integration for Enhanced PerformanceA sandwich press OEM collaborated with a tech-savvy startup to integrate smart features into their products. This fusion of traditional kitchenware with cutting-edge technology resulted in a line of sandwich presses that could be controlled via smartphone apps, allowing users to monitor cooking times and temperatures remotely. The success of this partnership was evident in the rise of the brand’s profile and the innovative approach it brought to the market.

D. Sustainability and Eco-Friendly InitiativesOne OEM partnership focused on sustainability by developing an eco-friendly sandwich press. The press was crafted from recycled materials, and its design emphasized energy efficiency. This environmentally conscious approach was well-received by eco-aware consumers, leading to a successful launch and a positive brand image for both the OEM and the client company.

E. Leveraging Global Supply Chains for Cost-Effective SolutionsAn OEM worked with a multinational corporation to streamline the production process, leveraging global supply chains to create cost-effective sandwich presses. By sourcing components from various countries with competitive pricing, the partnership was able to offer affordable yet high-quality products. This cost-saving strategy enhanced the market competitiveness and allowed the client to offer more value to their customers.

F. Customization for Niche MarketsAn OEM collaborated with a niche market brand to create a unique sandwich press designed for specific dietary preferences. For example, a gluten-free sandwich press that allowed users to toast bread with minimal oil, catering to health-conscious consumers. This partnership highlighted the ability of OEMs to cater to the needs of smaller, specialized markets, often overlooked by larger players.

G. Collaboration for Quality ControlIn a bid to maintain the highest standards of quality, an OEM formed a partnership with a reputable kitchen appliance brand. Together, they established rigorous quality control measures, ensuring that every sandwich press that left the factory met the brand’s stringent specifications. This alliance resulted in a product that customers could trust, reinforcing the brand’s reputation for excellence.

H. Joint Marketing Efforts for Enhanced Brand AwarenessSeveral OEMs have successfully partnered with client companies to launch new sandwich press lines. Through coordinated marketing campaigns, these partnerships have boosted brand awareness and customer engagement. From influencer collaborations to social media challenges, the combined efforts of OEMs and client brands have created a buzz around the latest sandwich press innovations.

In conclusion, successful OEM partnerships in the sandwich press industry are marked by a blend of innovation, market understanding, and strategic collaboration. These alliances have led to groundbreaking products, expanded market reach, and enhanced customer satisfaction, solidifying the role of OEMs as key players in driving the industry forward.

In the ever-evolving world of sandwich presses, technology is advancing at a rapid pace, bringing forth a host of new trends that promise to reshape the industry. From smart features to eco-friendly designs, here’s a glimpse into the future of sandwich press technology.

The integration of smart technology is becoming increasingly common in sandwich presses. Users are now looking for appliances that not only deliver the perfect sandwich but also offer convenience and connectivity. Features like touchscreens, digital timers, and pre-programmed settings are becoming standard, allowing for precise control over cooking times and temperatures.

Sustainability is another key trend shaping the future of sandwich press technology. As consumers become more environmentally conscious, manufacturers are responding by creating energy-efficient models. This includes using recycled materials, designing for longevity to reduce waste, and incorporating features that minimize energy consumption.

Customization is also on the rise, with sandwich presses now offering a variety of press plates and attachments. Users can choose from different textures and shapes to suit their preferences, whether they’re making classic sandwiches, paninis, or even avocado toast. This level of personalization is driving innovation in design and functionality.

The use of advanced materials is revolutionizing the construction of sandwich presses. Non-stick coatings are becoming more durable and easier to clean, while materials like ceramic and stainless steel are being used to enhance heat distribution and durability. These materials not only improve the cooking performance but also extend the lifespan of the appliance.

Safety features are being prioritized in the latest sandwich press models. From automatic shut-offs to cool-touch handles, manufacturers are focusing on creating appliances that protect users from accidents. Additionally, with the rise of smart appliances, safety is being integrated with connectivity, allowing for remote monitoring and control to prevent overheating or other hazards.

Another trend is the emphasis on health and wellness. Sandwich presses are being designed with features that make it easier for users to prepare nutritious meals at home. This includes adjustable heat settings that allow for the cooking of sandwiches with less oil, and even models that can be used to cook vegetables or meats in a healthier way.

The rise of social media and online content has also influenced sandwich press technology. Influencers and home chefs are pushing for more creative and visually appealing designs. As a result, manufacturers are focusing on aesthetics, offering a range of colors and styles that cater to different tastes and kitchen decors.

In the realm of connectivity, the Internet of Things (IoT) is making its way into kitchen appliances, including sandwich presses. Users can now control their appliances through smartphones or smart home systems, adding a new layer of convenience and integration with other smart devices in the home.

Lastly, the global market is driving innovation in sandwich press technology. As these appliances become more popular across the globe, manufacturers are adapting to different voltage systems, like the 120V/240V dual voltage feature, to ensure compatibility worldwide.

The future of sandwich press technology is bright and filled with possibilities. From smart features to sustainable designs, the industry is poised to continue evolving, offering consumers a wider range of options to satisfy their culinary desires. Whether it’s a simple sandwich or a gourmet creation, the sandwich press of tomorrow promises to be more versatile, efficient, and tailored to the needs of the modern consumer.

The dual voltage revolution in sandwich presses is not just a fleeting trend; it’s a game-changer that’s reshaping the industry. As we delve into the conclusion of this exploration, it’s clear that embracing this innovation is more than just a smart move—it’s a necessity for anyone looking to stay ahead in the competitive sandwich press market. The benefits of dual voltage technology are undeniable, and the challenges it presents are opportunities for growth and improvement. As we look to the future, the potential for further advancements in sandwich press technology is vast, and the industry is poised to evolve in exciting ways. Here’s why the dual voltage revolution is here to stay and how it’s poised to redefine the landscape of sandwich presses.