Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In a world where culinary trends evolve at a rapid pace, the industrial panini press has emerged as a versatile and indispensable tool in commercial kitchens. This article delves into the fascinating journey of the industrial panini press, exploring its innovative features, the growing market demand, successful case studies, design trends, consumer benefits, maintenance tips, and what the future holds for this remarkable kitchen appliance.

In the ever-evolving world of culinary innovation, the industrial panini press has emerged as a revolutionary tool that’s reshaping the landscape of commercial kitchens. Once a staple in local delis and sandwich shops, these versatile machines are now finding their way into the hearts of chefs and food service professionals worldwide. Let’s dive into why the industrial panini press has become such a game-changer in the kitchen.

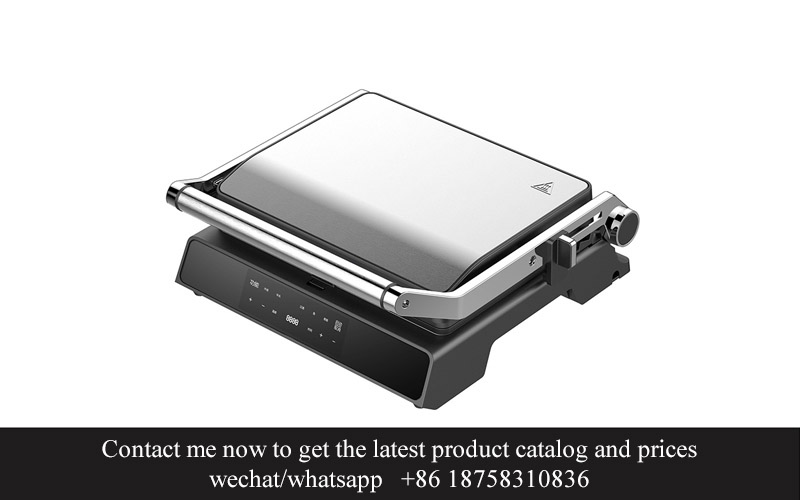

With their sturdy construction and powerful heating elements, industrial panini presses are designed to withstand the demands of high-volume food service operations. They are built to last, ensuring that restaurants and cafes can rely on them for years to come. The robust design not only guarantees durability but also allows for quick and consistent cooking, a crucial factor in maintaining service speed and customer satisfaction.

One of the standout features of industrial panini presses is their ability to cook a variety of food items, not just sandwiches. Chefs are using these presses to toast flatbreads, melt cheese on wraps, and even create delightful panini-style dishes with a multitude of fillings. The adjustable temperature settings and precise heating elements mean that each dish is cooked to perfection, with a golden-brown crust and melted cheese that simply can’t be matched by other cooking methods.

The versatility of industrial panini presses extends beyond just the variety of foods they can prepare. They are also incredibly adaptable to different kitchen layouts and styles. From countertop models to those designed to fit under the counter, these presses can be tailored to fit the needs of any commercial kitchen space. This adaptability makes them a valuable addition to any establishment looking to enhance its menu offerings without the need for extensive kitchen renovations.

In terms of efficiency, industrial panini presses are a dream come true for busy kitchen staff. They are capable of cooking multiple sandwiches at once, significantly reducing wait times and increasing the speed of service. This efficiency is especially critical during peak hours, when every second counts and customer satisfaction hinges on quick and accurate service.

The rise of the industrial panini press can also be attributed to the increasing demand for fresh and made-to-order menu items. Consumers are becoming more health-conscious and are looking for food options that align with their dietary preferences. The ability of these presses to heat up ingredients on the spot means that restaurants can offer a range of customizable sandwiches, wraps, and flatbreads that cater to a wide array of tastes and needs.

Safety is another crucial aspect that the industrial panini press delivers. These machines are designed with safety in mind, featuring non-slip surfaces and automatic shut-off functions in case of over-cooking or extended use. This ensures that kitchen staff can work confidently, knowing that their equipment is reliable and safe.

The convenience factor cannot be overstated. Industrial panini presses are easy to clean and maintain, which is a huge plus for busy kitchens. They also help to reduce food waste by allowing for precise control over the cooking process, ensuring that ingredients are heated evenly and to the right temperature without any overcooking.

From a cost perspective, the investment in an industrial panini press can be seen as a smart long-term decision. While the initial cost may be higher than that of a home or countertop model, the durability and efficiency of these machines mean that they can pay for themselves through increased productivity and reduced downtime.

In conclusion, the rise of the industrial panini press is a testament to the ever-changing demands of the food service industry. These versatile, durable, and efficient machines have become an essential tool for chefs and food service professionals looking to enhance their offerings and provide a superior dining experience. As the culinary landscape continues to evolve, the industrial panini press is poised to remain a staple in commercial kitchens around the world.

Industrial panini presses have been making quite the stir in the culinary world, and for good reason. These robust machines aren’t just for your local café or sandwich shop—they’re revolutionizing kitchens everywhere. Let’s delve into what sets these presses apart and why they’re becoming the talk of the town.

The sheer size and build of industrial panini presses are a testament to their commercial capabilities. Designed to withstand constant use, they are far more durable than their residential counterparts. The sturdy construction ensures that they can handle high volumes of sandwiches without succumbing to wear and tear.

One of the standout features of industrial panini presses is their even heat distribution. This is crucial for achieving that perfect, golden-brown crust that keeps customers coming back for more. With precision control over temperature, these presses guarantee consistency, making it easy to replicate the signature taste and appearance of a professional-grade panini.

Another aspect that has chefs and operators raving is the speed at which these presses can cook. In a busy kitchen, time is of the essence, and industrial panini presses can toast and press sandwiches in mere seconds. This rapid cooking time not only increases efficiency but also allows for a shorter wait time for customers, enhancing their overall dining experience.

The versatility of industrial panini presses is unmatched. They’re not just for making traditional paninis; they can also toast bagels, press burgers, and even create a variety of other delicious handheld treats. This multi-functional aspect means that restaurants and cafes can expand their menu options without the need for additional equipment.

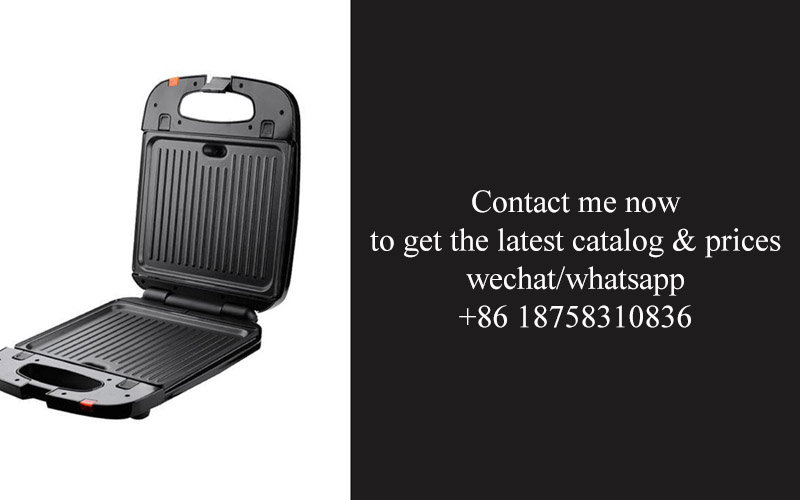

Ease of use is another factor that can’t be overlooked. Industrial panini presses are designed with convenience in mind. Many models come with non-stick surfaces that prevent sticking and make cleanup a breeze. The adjustable pressure settings allow operators to tailor the cooking process to the type of food being prepared, ensuring that every sandwich is cooked to perfection.

Safety is a top priority in commercial kitchens, and industrial panini presses have been engineered with this in mind. Features like cool-touch handles and automatic shut-offs add an extra layer of security, reducing the risk of accidents and burns.

Customization is also a key element that makes these presses stand out. Operators can choose from various sizes and configurations to fit their specific needs. Whether you’re running a bustling café or a high-end restaurant, there’s an industrial panini press out there that can meet your demands.

The design of these presses is sleek and modern, fitting seamlessly into any kitchen environment. They come in a range of finishes, from stainless steel to black, ensuring that they complement the existing décor without standing out too much.

The technology inside industrial panini presses is also impressive. Advanced heating elements ensure that the presses maintain consistent temperatures throughout their operation, while built-in timers allow for precise control over cooking times.

In the realm of sustainability, industrial panini presses shine as well. They are energy-efficient, using less power to achieve the same results as less efficient models. This not only helps reduce operating costs but also contributes to a greener kitchen environment.

Maintenance is a straightforward process with these presses. Regular cleaning and occasional descaling are all that’s required to keep them in top condition. This low maintenance aspect is a huge draw for busy kitchen staff who need to manage multiple tasks simultaneously.

The quality of the components used in industrial panini presses is top-notch. High-quality materials ensure that these machines will last for years, providing a great return on investment for any establishment.

Lastly, the reputation of the brands that manufacture these presses speaks volumes. With a history of producing reliable and innovative kitchen equipment, these brands have earned the trust of professionals worldwide.

In conclusion, the reasons why industrial panini presses are causing such a buzz are clear. Their durability, versatility, efficiency, safety, and modern design make them an invaluable asset to any kitchen. As the demand for quick, high-quality sandwiches continues to grow, these presses are poised to become an indispensable part of the culinary landscape.

Industrial panini presses have transcended their origins as simple kitchen gadgets, evolving into versatile tools that are now a staple in various culinary settings. This transformation is a testament to their adaptability, making them a go-to choice for everything from local delis to bustling commercial kitchens.

In the heart of the local deli, the industrial panini press has become a silent hero, ensuring that each sandwich is pressed to perfection. These presses are designed to handle the demands of a busy lunchtime rush, providing a consistent texture and temperature that keeps customers coming back for more. The adjustable heat settings allow for customization, whether it’s a warm, melting cheese sandwich or a crisp, toasty delight with all the fixings.

Commercial kitchens, on the other hand, have embraced the industrial panini press for its ability to streamline operations. The larger models can accommodate multiple sandwiches at once, reducing wait times and increasing efficiency. This is particularly crucial in fast-food establishments where speed is of the essence. The presses are built to withstand rigorous use, with durable materials and easy-to-clean surfaces that are essential in high-traffic environments.

Restaurants that offer a variety of grilled sandwiches and wraps have found that the industrial panini press is a versatile addition to their menu. It’s not just limited to traditional paninis; chefs are now experimenting with different types of bread, from ciabatta to pita, and even brioche, to create unique culinary experiences. The press can handle these variations with ease, allowing for creative freedom in the kitchen.

The versatility of industrial panini presses extends beyond just breads and cheeses. Many models come with non-stick surfaces that prevent sticking and make it possible to cook a variety of ingredients, from vegetables to proteins. This feature is particularly appealing to health-conscious consumers who are looking for quick, on-the-go meals that are both delicious and nutritious.

In the world of gourmet sandwiches, the industrial panini press has become a tool for craft and precision. Chefs can control the cooking time and temperature, ensuring that each ingredient is cooked to its peak flavor. The even pressure applied by the press helps to seal in the flavors and retain the juices, which is especially important for sandwiches that contain wet ingredients like tomatoes or lettuce.

The portability of these presses is also a key factor in their versatility. Many models are lightweight and compact, making them easy to move around the kitchen or even take to outdoor events. This flexibility is invaluable for caterers and event planners who need to provide high-quality food on the go.

In addition to the obvious use in sandwiches, the industrial panini press has found its way into other culinary applications. It’s not uncommon to see them used to prepare flatbreads, grilled cheese, or even as a substitute for a grill in a commercial setting. This multi-functionality means that the press can save valuable counter space and reduce the need for multiple appliances.

The user-friendliness of these presses is another reason for their widespread adoption. They are easy to operate, with intuitive controls that allow for quick adjustments. This ease of use is particularly beneficial in environments where staff turnover is high, ensuring that new employees can quickly learn how to use the equipment effectively.

The industrial panini press has also become a favorite among food trucks and mobile vendors. The compact size and ability to cook a variety of foods make them perfect for these on-the-move operations. Customers can enjoy freshly prepared paninis and wraps without having to wait for them to be cooked on a conventional grill.

In summary, the industrial panini press has earned its place in a variety of culinary settings due to its versatility. Whether it’s in a local deli, a busy commercial kitchen, a gourmet sandwich shop, or a food truck, this versatile appliance continues to be a game-changer in the kitchen, offering a wide range of possibilities for chefs and foodservice professionals alike.

Industrial panini presses have surged in popularity, becoming a staple in both local delis and bustling commercial kitchens. Their versatility is undeniable, as these robust machines can transform a variety of ingredients into mouthwatering sandwiches with ease. Let’s delve into the innovative features that make these presses stand out.

One standout feature is the adjustable pressure settings. Not all paninis are created equal, and the ability to tweak the pressure allows chefs to cater to different preferences. Some diners might prefer a slightly toasted exterior with a soft, tender interior, while others might enjoy a crisp, golden-brown crust with a well-done filling. The variable pressure settings on industrial presses ensure that every sandwich meets these diverse expectations.

Another key feature is the non-stick surface. This is a game-changer for busy kitchens, as it reduces the need for constant oiling and makes cleanup a breeze. The non-stick coating also prevents food from sticking to the plates, ensuring that each sandwich is perfectly shaped and free from unwanted residue.

The size and capacity of an industrial panini press are crucial for high-volume operations. These presses often come with large plates that can accommodate multiple sandwiches at once, streamlining the cooking process. For instance, a press with a 12-inch plate can cook up to four sandwiches simultaneously, significantly cutting down on wait times during peak hours.

Temperature control is another essential feature. Consistent heat distribution is vital for achieving that perfect panini texture. Industrial presses typically offer precise temperature control, allowing chefs to maintain the ideal cooking temperature for different types of bread and fillings. This ensures that each sandwich is cooked to perfection, with a perfectly toasted crust and a warm, melted filling.

Some models come equipped with a programmable timer, which is a huge advantage in fast-paced kitchens. The ability to set a specific cooking time means that operators can ensure every sandwich is cooked to the same standard, without the risk of overcooking or undercooking. This feature is particularly beneficial for large orders, as it guarantees consistency across all servings.

Safety features are also a priority in industrial panini presses. Many models include an automatic shut-off function, which turns off the press after a predetermined period of inactivity. This not only prevents potential fires but also conserves energy. Additionally, some presses have cool-touch handles and a safety lock to prevent accidental operation when the press is open.

The design of an industrial panini press is also a factor to consider. A sleek, modern design not only looks appealing but also takes up less space on the kitchen counter. Compact presses are ideal for tight kitchens, while larger models can be used as a centerpiece for more open spaces. Some presses even come with a foldable design, making them easy to store when not in use.

Ease of maintenance is another important feature. Kitchens are bustling environments, and keeping equipment clean and in good working order is essential. Industrial panini presses with removable plates and drip trays make cleaning a quick and straightforward process. This is especially important for health and safety reasons, as it ensures that the equipment is ready for use at all times.

Lastly, the build quality of an industrial panini press should not be overlooked. These machines are designed to withstand the rigors of commercial use, so durability is key. Look for presses made from high-quality materials that can withstand high temperatures and frequent use without warping or breaking.

In summary, the innovative features of an industrial panini press make it a versatile and reliable tool for any kitchen. From adjustable pressure and non-stick surfaces to programmable timers and safety features, these presses are designed to enhance efficiency, consistency, and safety in the cooking process. When selecting an industrial panini press, consider these features to ensure you choose the best option for your specific needs.

In recent years, the demand for industrial panini presses has surged, reflecting a shift in the culinary landscape. Here’s a deeper dive into the factors fueling this growth:

The rise of fast-casual dining: With the increasing popularity of fast-casual restaurants, there’s a greater need for efficient, high-quality food preparation. Industrial panini presses fit this bill perfectly, allowing for quick and consistent sandwich assembly.

Health-conscious consumers: As more people opt for healthier eating habits, the demand for fresh, homemade sandwiches has soared. Industrial presses enable restaurants to offer a variety of sandwiches, from classic ham and cheese to gourmet creations, all made on the spot.

The convenience factor: Busy lifestyles have led to a preference for convenient food options. Industrial panini presses provide a fast, easy way to prepare sandwiches that cater to customers seeking a quick bite without sacrificing taste.

Expansion of food trucks and pop-up restaurants: With the rise of food trucks and pop-up eateries, the need for portable and durable kitchen equipment has become crucial. Industrial panini presses are lightweight, easy to transport, and can withstand the rigors of mobile operations.

The global sandwich market: The sandwich market is not limited to a single region; it’s a global phenomenon. From Italy’s panini to Japan’s yakitori, the variety of sandwiches across cultures has expanded, and industrial presses can accommodate these diverse preferences.

Customization and personalization: Customers today want to feel like their meal is tailored to their tastes. Industrial panini presses allow for the customization of sandwiches, from choosing the type of bread to selecting the fillings, thus enhancing the customer experience.

The rise of gourmet sandwiches: The gourmet sandwich segment has seen significant growth, with high-end restaurants and foodies alike embracing creative, flavor-packed sandwiches. Industrial presses are capable of handling the heat required to achieve the perfect melt in cheese and the right amount of crispness in the bread.

Increased focus on sustainability: As businesses look to reduce their environmental footprint, using energy-efficient kitchen equipment becomes a priority. Many modern industrial panini presses are designed with energy-saving features, appealing to eco-conscious operators.

Technological advancements: The evolution of industrial panini presses includes the integration of new technologies, such as digital controls and non-stick surfaces, which make them easier to use and maintain.

The impact of social media: With the rise of social media, food trends spread like wildfire. The visually appealing nature of sandwiches made on industrial presses has made them a favorite for food photographers and influencers, further boosting their popularity.

Diverse applications: Industrial panini presses aren’t just for sandwiches. They can also be used to cook wraps, pizzas, and even some types of flatbreads, making them a versatile addition to any kitchen.

The economic downturn’s silver lining: While the global economic downturn has impacted many industries, it has also encouraged people to seek affordable yet satisfying meal options. Industrial panini presses provide a cost-effective solution for creating these meals.

The importance of speed in service: In the fast-paced food service industry, speed is key. Industrial panini presses can handle a high volume of orders quickly, ensuring that customers receive their food promptly.

The integration of panini presses in retail settings: Retail stores have also recognized the value of industrial panini presses, using them to offer grab-and-go sandwiches alongside their regular products.

The potential for international expansion: As the demand for industrial panini presses grows, so does the potential for international expansion. Manufacturers are looking to export their products to new markets, capitalizing on the global interest in this versatile piece of equipment.

In conclusion, the growing demand for industrial panini presses is a multifaceted trend that reflects changing consumer preferences, technological advancements, and the evolving landscape of the food service industry.

In the bustling food service industry, industrial panini presses have emerged as a staple for many businesses, offering a unique and efficient way to serve up delicious sandwiches. Let’s delve into a few case studies that showcase the successful implementations of these versatile appliances.

The Coffee Shop Success Story: A popular local coffee shop decided to introduce a new menu item: the panini. By investing in an industrial panini press, they were able to offer a variety of hot sandwiches that quickly became a hit. The press’s even heating and pressure-sealing capabilities ensured consistent, high-quality results, which in turn, increased customer satisfaction and repeat visits.

The Fast-Casual Chain’s Menu Expansion: A fast-casual chain was looking to diversify its menu with a new offering that would stand out. After testing various cooking methods, they settled on an industrial panini press. The case study revealed that the press’s ability to cook sandwiches in just a few minutes, with a perfect crust, was a game-changer for their busy kitchen. The chain saw a significant increase in sales of the new menu item, and it became a favorite among their customers.

The Gourmet Restaurant’s Culinary Innovation: A gourmet restaurant known for its exquisite cuisine wanted to add a touch of innovation to its menu. They incorporated an industrial panini press into their kitchen, allowing them to create gourmet sandwiches with unique flavor profiles. The press’s ability to lock in flavors and achieve a perfect sear on the bread was a hit with patrons, who appreciated the fusion of traditional and modern culinary techniques.

The Sports Bar’s Fan Favorite: A sports bar sought to offer a quick and satisfying meal option for its customers. By installing an industrial panini press, they introduced a variety of themed sandwiches that catered to different tastes and preferences. The press’s speed and efficiency allowed the bar to serve up freshly cooked paninis in no time, making it a fan favorite during game-time.

The Catering Service’s Mobile Kitchen Solution: A catering service faced the challenge of providing high-quality food at events where traditional cooking methods were not feasible. They turned to an industrial panini press, which allowed them to cook sandwiches on-site, ensuring that each dish was freshly prepared. The press’s portability and ease of use made it an ideal solution for their mobile kitchen, and the catering service received glowing reviews for their delicious panini offerings.

The Community Café’s Sustainability Effort: A community café aimed to reduce its carbon footprint and support local farmers. They chose to use an industrial panini press to serve sandwiches made with locally sourced ingredients. The press’s efficient cooking process reduced energy consumption, and the café’s commitment to sustainability resonated with customers, who appreciated the fresh, high-quality food and the café’s eco-friendly stance.

The College Campus Diner’s Student Appeal: A campus diner wanted to attract students with a quick, affordable, and delicious meal option. They introduced a panini bar using an industrial panini press, offering a variety of customizable sandwiches. The press’s ability to cook a sandwich in minutes was perfect for the time-pressed students, and the diner saw a surge in sales as students enjoyed their custom-made meals.

The Hotel’s Breakfast Buffet Enhancement: A hotel sought to upgrade its breakfast buffet with a unique feature that would set it apart from competitors. They installed an industrial panini press, allowing guests to watch as their sandwiches were freshly cooked. The interactive experience added a new dimension to the buffet, and guests raved about the quality and taste of the paninis, contributing to positive reviews and increased room bookings.

These case studies highlight the versatility and success of industrial panini presses in the food service industry. From local delis to large-scale catering operations, these appliances have proven to be a valuable asset in creating a variety of delicious sandwiches that satisfy customers and enhance the dining experience.

The evolution of industrial panini presses has been a fascinating journey, reflecting not just technological advancements but also changing consumer preferences and market demands. From the humble beginnings of flatbread sandwiches to the high-tech machines gracing commercial kitchens today, here’s a glimpse into how these presses have evolved in design.

The Traditional Press: A Simple Yet Effective ToolEarly industrial panini presses were straightforward, featuring a single, flat plate that compressed the sandwich uniformly. These units were often large and bulky, designed to handle the high volume required in commercial settings. The design was functional, focusing on even heating and pressing without the complexities of modern units.

The Introduction of Double-Deck PressesAs the popularity of panini sandwiches grew, so did the need for more even pressing. Double-deck presses emerged, with two heating plates that sandwiched the bread and filling, ensuring consistent results. This design allowed for a more controlled cooking process, and the units began to feature adjustable pressure controls to cater to different types of bread and fillings.

The Emergence of Digital ControlsThe introduction of digital controls marked a significant shift in industrial panini press design. These new features allowed operators to set precise temperatures and cooking times, which was especially important for maintaining consistency across a high-volume operation. Digital displays and programmable settings made it easier for chefs to customize the cooking process to their specific menu items.

The Rise of Non-Stick SurfacesOne of the most practical advancements in design was the adoption of non-stick surfaces on the pressing plates. This feature not only made cleaning easier but also reduced the risk of food sticking to the plates, which could lead to burning and a shorter lifespan for the press. Non-stick coatings also improved the overall hygiene of the cooking process.

Modular and Compact DesignsIn response to space constraints in modern kitchens, manufacturers started to produce more modular and compact designs. These presses were not only smaller in size but also designed to be stackable or mounted on walls, maximizing space efficiency. This shift was particularly welcomed in bustling cafes and delis where every square inch of space counted.

Enhanced Safety FeaturesSafety has always been a top priority in commercial kitchen equipment, and industrial panini presses are no exception. Modern designs now include features like automatic shut-off after a certain period of inactivity, ensuring that the press doesn’t overheat or pose a fire hazard. Some models also feature temperature sensors to prevent burning and provide alerts if the internal temperature exceeds safe limits.

Integration with Modern Cooking TechniquesThe evolution of industrial panini presses has also seen them integrating with other modern cooking techniques. For instance, some models now offer a combination of panini pressing with grilling capabilities, allowing for the creation of a wider range of dishes beyond just sandwiches. This versatility has made them a more valuable addition to any kitchen that wants to offer a diverse menu.

The Integration of Smart TechnologyIn recent years, the integration of smart technology has taken industrial panini presses to a new level. Some models now come with Wi-Fi connectivity, allowing operators to monitor and control the presses remotely. This feature is particularly useful for managing multiple presses in large operations, ensuring that each unit is operating at optimal conditions at all times.

Sustainability and Energy EfficiencyAs sustainability becomes a key concern in the food industry, manufacturers have started to focus on energy-efficient designs. Newer models of industrial panini presses are designed to consume less power while still delivering the same high-quality results. Features like energy-saving modes and efficient heating elements are becoming standard, reducing the carbon footprint of commercial kitchens.

The Evolution of AestheticsFinally, the design of industrial panini presses has also evolved aesthetically. Modern units are not just functional but also visually appealing, fitting seamlessly into the modern kitchen environment. The sleek, clean lines and stainless steel finishes of contemporary presses add a touch of elegance to any kitchen space.

In conclusion, the evolution of industrial panini presses is a testament to the ingenuity of kitchen equipment designers. From simple, functional tools to sophisticated, smart appliances, these presses have come a long way, offering commercial kitchens a versatile and efficient way to prepare one of the most beloved comfort foods.

In the world of culinary innovation, industrial panini presses have emerged as a favorite among chefs and business owners alike. These appliances are not just limited to crafting the perfect sandwich; they’ve become a staple in a variety of commercial kitchens. Let’s delve into why these presses are the talk of the town.

The precision and efficiency of industrial panini presses are unparalleled. These machines are designed to ensure consistent heat distribution, allowing chefs to create a golden-brown crust on each sandwich with ease. The even cooking temperature is a game-changer for establishments looking to maintain a high level of quality across their menu.

For those who value speed, industrial panini presses are a godsend. The quick cooking time means shorter wait times for customers, which is crucial in a fast-paced restaurant environment. The ability to serve more customers in less time can significantly boost sales and improve overall customer satisfaction.

One of the standout features of industrial panini presses is their versatility. They can handle a wide range of foods, from traditional sandwiches to wraps, paninis, and even flatbreads. This flexibility is particularly beneficial for kitchens that aim to offer a diverse menu or for those looking to keep up with changing trends.

The design of industrial panini presses has also evolved to cater to the needs of modern kitchens. Many models now come with adjustable heat settings, allowing chefs to customize the cooking temperature according to their specific recipes. Some even feature non-stick surfaces that make cleanup a breeze.

Durability is another aspect that has been meticulously considered in the design of these presses. Constructed with high-quality materials, they are built to withstand the rigors of daily commercial use. The sturdy build ensures that these appliances can last for years, reducing the need for frequent replacements.

Chefs and business owners are also drawn to the ease of use of industrial panini presses. With simple, intuitive controls, operators can quickly adjust settings and get to work. This ease of operation is especially important for training new staff or ensuring consistency in food preparation.

Another benefit is the space-saving design of these presses. Despite their size, they are compact enough to fit into most kitchen layouts without cluttering the workspace. This is particularly valuable in smaller kitchen environments where every inch counts.

Energy efficiency is a crucial factor in the minds of many business owners. Industrial panini presses are designed to be energy-efficient, helping to reduce utility bills and minimize the environmental impact. The energy-saving features are a testament to the commitment of manufacturers to sustainable practices.

Safety features are also a priority in the design of these presses. Many models include safety locks to prevent accidental operation, and some come with cool-touch handles to ensure that operators can safely remove sandwiches without the risk of burns.

In terms of consumer appeal, the high-quality, perfectly toasted sandwiches that industrial panini presses produce can be a significant draw for customers. The visually appealing and delicious results can increase the likelihood of repeat business and word-of-mouth referrals.

As the demand for convenience and quality dining continues to rise, the role of industrial panini presses in the food service industry is only set to grow. The integration of technology, such as digital temperature controls and programmable settings, is further enhancing the capabilities of these presses.

For chefs and business owners, the love for industrial panini presses is rooted in their ability to deliver consistent, high-quality results time after time. The benefits are clear: increased efficiency, versatility, durability, ease of use, and energy savings, all contributing to a more profitable and customer-friendly kitchen operation.

In the bustling world of commercial kitchens, where every second counts and quality is paramount, the industrial panini press has emerged as a reliable workhorse. These robust appliances are not just about pressing sandwiches; they are integral to the efficiency and profitability of a food service operation. Here’s a deep dive into why chefs and business owners alike are smitten with these industrial marvels.

The durability of industrial panini presses is unmatched. Crafted from high-quality stainless steel, they are built to withstand the rigors of a busy kitchen environment. The sleek design not only looks professional but also ensures that the heat distribution is even, which is crucial for consistent results. Business owners appreciate this reliability, knowing that a well-maintained panini press can last for years, making it a wise investment.

Efficiency is key in a commercial kitchen, and industrial panini presses excel in this department. With rapid heating capabilities, these presses can be ready to use in mere minutes, significantly reducing wait times for customers. The ability to cook multiple sandwiches at once not only increases throughput but also ensures that orders are processed quickly, keeping the line moving and the patrons happy.

The adjustable heat settings are another feature that chefs find invaluable. Whether it’s the perfect char on a grilled cheese or the right level of crispiness for a panini, these presses offer precise control. This versatility allows for a wider menu, from classic sandwiches to gourmet creations, which in turn can attract a broader customer base.

The non-stick surfaces are a game-changer for both chefs and cleaning staff. Say goodbye to the days of scraping off stubborn bits of bread from the press. The easy-to-clean surfaces not only save time but also reduce the risk of food particles affecting the taste and quality of subsequent sandwiches.

Safety is a top priority in the kitchen, and industrial panini presses are designed with this in mind. The locking mechanisms prevent accidental burns and ensure that the press remains secure during operation. The visible heat indicators give clear signals when the press is hot, minimizing the risk of burns to both staff and customers.

Maintenance is a crucial aspect of keeping your industrial panini press in top shape. Regular cleaning and inspection are essential to prevent any malfunctions. The ease of disassembly and the availability of replacement parts make maintenance straightforward. Business owners benefit from the fact that these presses are user-friendly and don’t require specialized training to operate or maintain.

Energy efficiency is another reason why chefs and business owners are drawn to industrial panini presses. These appliances are designed to minimize energy consumption without compromising on performance. This not only helps in reducing utility bills but also aligns with the growing trend towards sustainable practices in the food service industry.

The portability of some models is a bonus for businesses that might need to set up temporary stands or pop-up shops. The ability to move the press around with ease means that operators can cater to events and festivals without the hassle of finding a permanent kitchen space.

Customer satisfaction is the ultimate goal in the food service industry, and industrial panini presses play a significant role in achieving that. The consistent quality of the sandwiches they produce, combined with the speed and ease of use, means that customers can enjoy their meals promptly and with delight.

In the competitive landscape of the food service industry, staying ahead means embracing innovations that streamline operations and enhance the customer experience. Industrial panini presses have proven to be a valuable tool in this quest. From their durable construction to their user-friendly features, these appliances are a testament to the evolution of kitchen technology. They are not just a part of the kitchen equipment; they are an extension of the chef’s skill and the business owner’s vision.

The evolution of technology has significantly impacted the food service industry, and industrial panini presses are no exception. These versatile appliances have become a staple in commercial kitchens, from local delis to bustling restaurants. They’ve transformed the way sandwiches are made, offering a level of consistency and efficiency that traditional methods cannot match. Let’s delve into the future of industrial panini presses and what we can anticipate in the coming years.

The demand for convenience and speed in the food service sector continues to rise, and industrial panini presses are perfectly poised to meet these needs. With their ability to cook multiple sandwiches at once, these machines have become a cornerstone in high-volume operations. However, the future is not just about cooking speed; it’s about innovation and sustainability.

One trend we can expect to see is the integration of smart technology into industrial panini presses. These smart features could include wireless connectivity, allowing for remote monitoring and control of the machine’s settings. Imagine being able to adjust the temperature or cooking time from your smartphone while you’re on the go. This level of connectivity could lead to more efficient operations and even predictive maintenance, reducing downtime and extending the life of the equipment.

Energy efficiency is another area where industrial panini presses are likely to evolve. As sustainability becomes a more pressing concern for businesses and consumers alike, manufacturers will focus on creating appliances that consume less power without compromising on performance. This could involve the development of more advanced heating elements and improved insulation, ensuring that the presses not only cook quickly but also do so with minimal energy use.

Customization is also a factor that’s set to grow. In the future, industrial panini presses may offer a range of interchangeable plates and attachments, allowing operators to cater to a variety of dietary preferences and menu items. From gluten-free to vegan options, the ability to tailor the cooking surface to specific needs will be a game-changer for kitchens looking to diversify their offerings.

Material advancements are another aspect we should keep an eye on. As manufacturers strive to create more durable and reliable equipment, we may see the use of new materials that are not only robust but also lightweight. This would not only make the presses easier to handle but also reduce the overall weight of the appliance, potentially lowering shipping costs and improving the environmental footprint.

Safety features are paramount in any kitchen, and the future of industrial panini presses will likely see an emphasis on this aspect as well. Improved safety mechanisms, such as automatic shut-offs in case of overheating or blockages, will be standard. Additionally, user-friendly interfaces and clear safety warnings will help prevent accidents and ensure that operators can work confidently.

The future of industrial panini presses also hinges on the adoption of new cooking techniques. We might see the integration of steam or infrared heating, which could provide a healthier cooking option compared to traditional methods. These alternative cooking methods could be particularly appealing to health-conscious consumers and those looking to offer a variety of menu items that cater to different dietary requirements.

Innovation in the form of modular design is also on the horizon. Kitchens are always evolving, and having a panini press that can be adapted to fit new layouts or equipment changes is a significant advantage. Modular presses could be designed with interchangeable parts, allowing for easy upgrades and repairs without the need for a complete replacement.

Lastly, the future of industrial panini presses will be shaped by the needs of the end-users—the chefs and business owners. As such, we can expect to see a greater focus on user experience. This could manifest in the form of intuitive controls, ergonomic designs, and user training programs that help operators get the most out of their equipment.

In conclusion, the future of industrial panini presses is bright and filled with potential. From smart technology and energy efficiency to customization and safety, these appliances are set to evolve in ways that will not only improve the efficiency of commercial kitchens but also enhance the quality and variety of the food they produce. As the industry continues to grow and change, so too will the industrial panini press, ensuring it remains a vital tool for any kitchen looking to stay ahead of the curve.