Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In the bustling world of commercial kitchens, the sandwich press has emerged as a game-changer, offering a quick and efficient way to craft mouthwatering sandwiches. But with the plethora of options available, choosing the right sandwich press can be a daunting task. That’s where the NSF-approved sandwich press steps in, promising quality, safety, and innovation. Today, we delve into the world of these sandwich presses, exploring their features, benefits, and the future they hold for the culinary landscape.

In recent years, the commercial sandwich press has seen a meteoric rise in popularity, becoming a staple in countless cafes, restaurants, and food service establishments. This surge in demand can be attributed to several factors that have reshaped the foodservice industry.

The convenience and speed at which a sandwich press can prepare a delicious, toasted sandwich have made it a favorite among busy diners and operators alike. With the increasing focus on fast-casual dining experiences, the ability to offer a quick yet satisfying meal has become a competitive advantage. As a result, the demand for commercial sandwich presses has skyrocketed.

Another key driver behind the rise of commercial sandwich presses is the versatility they offer. These appliances can handle a wide variety of ingredients, from classic ham and cheese to gourmet creations with avocado, smoked salmon, or even grilled vegetables. This adaptability has allowed sandwich shops to cater to diverse tastes and dietary preferences, expanding their customer base and menu options.

The culinary landscape has also evolved, with a growing trend towards healthier, heartier fare. Sandwich presses have stepped in to fill this niche, providing a way to prepare nutritious sandwiches with the added benefit of a crisp, toasted exterior. This has been particularly appealing to health-conscious consumers looking for a balanced meal on the go.

In the realm of innovation, manufacturers have been hard at work perfecting the design of commercial sandwich presses. Modern models now come with features like adjustable heat settings, non-stick surfaces, and even programmable options for different types of bread and fillings. These advancements have not only improved the quality of the final product but have also made the presses easier to use and maintain.

The convenience of these appliances extends beyond the kitchen. Their compact size and ease of cleaning have made them a practical choice for businesses looking to optimize their workspace. Moreover, the durability of commercial sandwich presses ensures they can withstand the rigors of a busy kitchen environment, making them a long-term investment for foodservice operators.

As the foodservice industry continues to evolve, the emphasis on sustainability has become more pronounced. Commercial sandwich presses that are energy-efficient and made from eco-friendly materials are gaining popularity. This shift towards more sustainable practices is not only good for the environment but also resonates with consumers who are increasingly concerned about the impact of their food choices.

The rise of the commercial sandwich press has also been fueled by the growth of food trucks and pop-up restaurants. These mobile operations often lack the space for large kitchen equipment, making the compact and efficient sandwich press an ideal solution. It’s no surprise that the demand for these presses has expanded into these niche markets as well.

Finally, the rise of social media and food blogs has played a significant role in the popularity of the commercial sandwich press. The ability to create visually appealing and appetizing sandwiches has become a key marketing tool for many foodservice businesses. The sandwich press has become a symbol of quality and innovation, often featured in promotional content to attract customers.

In conclusion, the rise of the commercial sandwich press is a testament to the evolving tastes and needs of the modern consumer. With its convenience, versatility, and technological advancements, the sandwich press has secured its place as a vital piece of equipment in the foodservice industry, and its popularity shows no signs of slowing down.

In today’s fast-paced culinary world, the demand for high-quality, consistent, and hygienic food preparation is paramount. The National Sanitation Foundation (NSF) approval has become a beacon of trust and quality for commercial kitchen equipment, especially for sandwich presses. Understanding what NSF approval entails can help operators make informed decisions about the equipment they choose to serve their customers.

NSF International is an independent, not-for-profit organization that writes standards and certification programs for products, services, and systems that improve public health and safety. When it comes to commercial sandwich presses, NSF certification ensures that the product meets stringent health, safety, and sanitation standards.

The process of obtaining NSF approval is rigorous and comprehensive. It involves a thorough review of the sandwich press’s design, materials, manufacturing process, and the effectiveness of its cleaning and maintenance procedures. This ensures that the press not only performs as advertised but also contributes to a safe and clean kitchen environment.

One of the key aspects of NSF approval is the material from which the sandwich press is made. It must be non-toxic and free from any harmful substances that could leach into the food. This is crucial for maintaining the integrity of the food being prepared and for the health of the consumers.

Moreover, NSF-approved sandwich presses must undergo rigorous testing to ensure that they can withstand the demands of a commercial kitchen. This includes evaluating the durability of the heating elements, the ability to maintain consistent temperatures, and the prevention of cross-contamination between different types of food items.

Another important factor in the certification process is the ease of cleaning and maintenance. Commercial kitchens are high-risk environments when it comes to foodborne illnesses, so equipment that is easy to clean and sanitize is essential. NSF-approved sandwich presses come with features that facilitate quick and thorough cleaning, reducing the risk of bacteria and other contaminants.

The thermal performance of a sandwich press is also a critical component of NSF approval. The device must be able to reach and maintain the appropriate temperatures required to cook the sandwiches properly. This not only ensures food safety but also contributes to the overall quality of the final product.

Additionally, NSF certification extends beyond the physical aspects of the sandwich press. It also covers the operational safety features, such as automatic shut-off mechanisms that prevent overheating and potential burns. This level of attention to safety is what sets NSF-approved equipment apart from lesser-quality alternatives.

For operators in the foodservice industry, the NSF mark is a mark of excellence. It signifies that the sandwich press has been evaluated by a third-party organization and has met or exceeded the industry’s highest standards. This can be a significant selling point for restaurants and cafes looking to attract health-conscious consumers and differentiate themselves from competitors.

The peace of mind that comes with NSF approval is invaluable. It allows operators to focus on what they do best—serving great food—without the added stress of worrying about the safety and quality of their equipment. Customers can also have confidence that the food they’re eating has been prepared in a clean and safe environment.

In summary, understanding NSF approval for commercial sandwich presses is about recognizing the value of a product that has been scrutinized and certified to meet the highest standards of health and safety. It’s an assurance that the sandwich press not only performs as intended but also contributes to the overall well-being of the kitchen staff and the public it serves. For those in the foodservice industry, NSF approval is not just a certification; it’s a commitment to excellence in every aspect of sandwich preparation.

The NSF approved sandwich press has become a game-changer in the commercial kitchen scene, offering a blend of innovation and functionality. Here are some of the key features and benefits that make this appliance stand out:

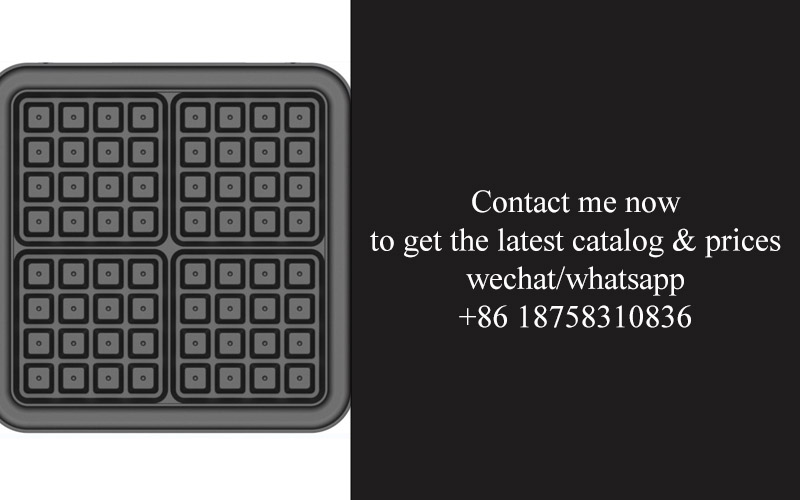

Consistent Heat Distribution: One of the standout features of the NSF approved sandwich press is its ability to maintain consistent heat across the entire cooking surface. This even heat ensures that every sandwich is cooked to perfection, with a golden-brown crust on the outside and a juicy, tender interior.

Non-Stick Coating: The interior of the press is coated with a high-quality non-stick material that not only prevents sticking but also makes cleanup a breeze. This is especially important in busy commercial kitchens where efficiency is crucial.

Adjustable Temperature Settings: With the ability to adjust the temperature according to the type of sandwich being prepared, the NSF approved sandwich press offers versatility. From classic ham and cheese to gourmet paninis, the precise heat control ensures the right level of doneness for each sandwich.

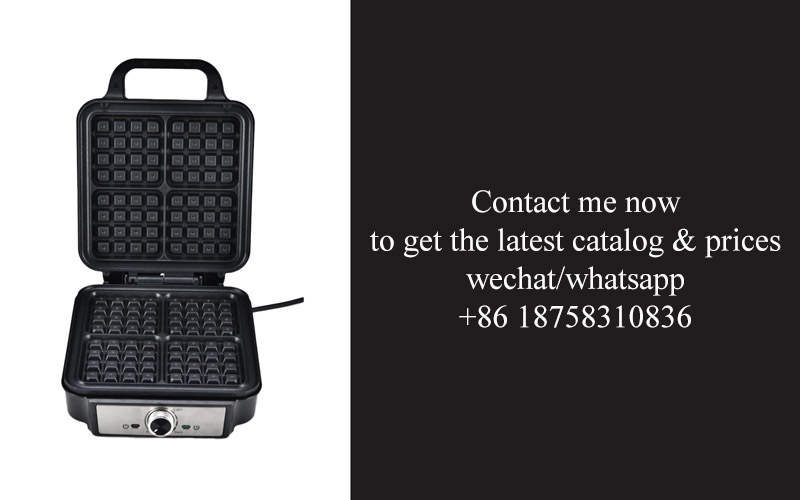

Quick and Efficient Cooking: Designed with speed in mind, this sandwich press can cook a sandwich in mere minutes. The rapid cooking time is a godsend for kitchens that serve a high volume of customers, ensuring that orders are turned around quickly without compromising on quality.

Safe and Easy to Use: The NSF certification ensures that the sandwich press meets stringent safety standards, including electrical and thermal safety. The appliance also features an easy-to-use interface with clear temperature controls and a simple on/off switch, making it accessible to all kitchen staff.

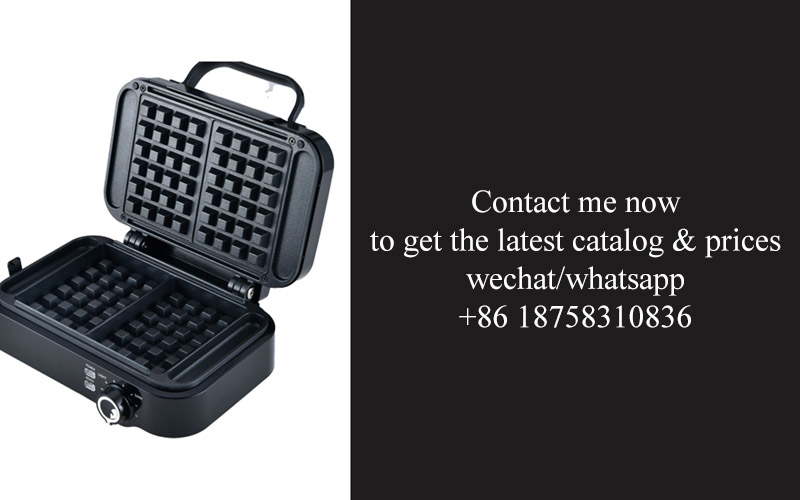

Space-Saving Design: Commercial kitchens often have limited space, and the NSF approved sandwich press is designed with this in mind. Its compact size allows for easy placement on countertops or in kitchen cabinets, maximizing the use of available space.

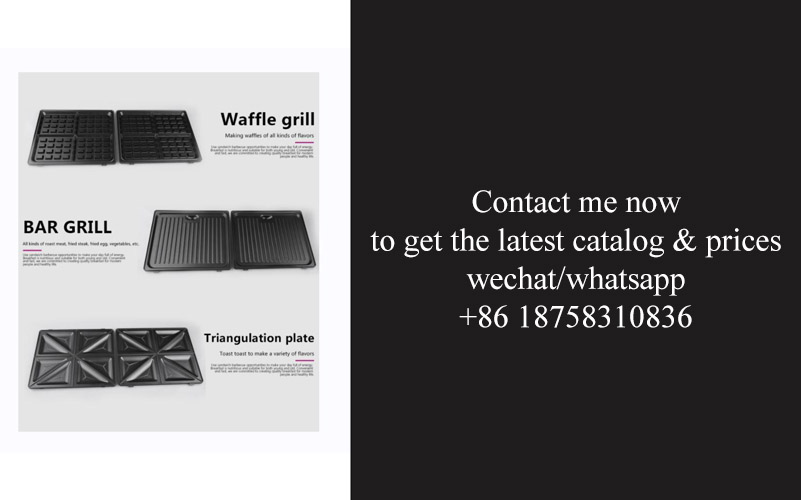

Versatile Cooking Capabilities: Beyond sandwiches, this press can be used to cook a variety of other items like wraps, paninis, and even small portions of pizza. The adjustable plates can accommodate different sizes and shapes, making it a versatile addition to any kitchen.

Durability: Crafted from high-quality materials, the NSF approved sandwich press is built to last. It can withstand the rigors of a busy commercial kitchen environment, withstanding heat, pressure, and regular use without compromising its performance.

Easy to Clean: The non-stick coating and the ability to remove the cooking plates for thorough cleaning ensure that the sandwich press remains hygienic and ready for use at all times. This feature is particularly beneficial in maintaining the highest levels of food safety.

Energy Efficient: Designed with energy efficiency in mind, the sandwich press uses less power than traditional cooking methods, which can help reduce utility bills and minimize the kitchen’s carbon footprint.

Enhanced Presentation: The even browning and cooking process of the sandwich press result in a visually appealing presentation. This can be a significant advantage for establishments that rely on food presentation to attract customers.

Customizable Cooking Experience: Some models of the NSF approved sandwich press offer additional features such as adjustable pressure settings or even a built-in searing function to give the sandwiches a distinctive charred flavor.

In summary, the NSF approved sandwich press is not just a cooking tool; it’s an investment in quality, efficiency, and safety for any commercial kitchen. Its features and benefits make it an essential appliance for any establishment looking to serve delicious, perfectly cooked sandwiches in a timely and professional manner.

In recent years, the design of commercial sandwich presses has undergone a remarkable transformation, merging functionality with innovation. Here’s a closer look at some of the latest developments in this area.

The sleek, modern aesthetics of new sandwich presses are not just for show. Many manufacturers are focusing on creating equipment that not only performs well but also complements the aesthetic of contemporary commercial kitchens. These presses often feature a streamlined design with a minimalist approach, which not only looks appealing but also minimizes the footprint on countertops.

One of the standout innovations is the integration of digital controls. These controls allow for precise temperature and pressure adjustments, ensuring consistent and high-quality results every time. Users can set specific parameters for each type of sandwich, making it easier to cater to different preferences and dietary requirements.

The use of non-stick surfaces has been refined with advanced coatings that are more durable and easier to clean. These surfaces not only prevent food from sticking but also reduce the need for butter or oil, which can cut down on calories and fat content. The ease of cleaning is also a significant benefit, as it saves time and effort for busy kitchen staff.

Many sandwich presses now come with adjustable plates. This feature allows operators to customize the sandwich size and shape, offering a wider variety of options to their customers. Whether it’s a classic six-inch sub or a gourmet hero, the ability to cater to different preferences enhances the appeal of the sandwich press in high-volume foodservice settings.

In terms of safety, modern sandwich presses incorporate various safety features. Auto shut-off functions are common, preventing the machine from overheating and reducing the risk of fire. Some models also include a cool-touch exterior, which is especially important in busy kitchens where spills and burns are a concern.

The inclusion of removable parts has also been a game-changer. Many sandwich presses now have plates, grids, and other components that can be easily removed and cleaned. This not only simplifies maintenance but also allows for quick and efficient cleaning between uses, which is crucial in a commercial kitchen environment.

Some models have even embraced eco-friendly design principles. They are made from sustainable materials and are energy-efficient, contributing to a greener kitchen operation. The reduced energy consumption not only lowers operational costs but also aligns with the growing demand for environmentally responsible practices in the foodservice industry.

Innovation in the design of sandwich presses has also led to the development of multifunctional units. Some presses can be used to toast bread, cook paninis, and even prepare other types of food items. This versatility is attractive to operators looking to maximize their equipment investment without compromising on quality.

Lastly, the user interface has seen improvements. Touchscreen displays and intuitive controls make it easier for staff to operate the sandwich press, even without extensive training. This user-friendly design is particularly beneficial in fast-paced environments where efficiency is key.

Overall, the innovations in sandwich press design reflect a commitment to quality, efficiency, and customer satisfaction. From aesthetic appeal to safety features and sustainability, these advancements are shaping the future of commercial sandwich preparation.

In recent years, the kitchen appliance market has seen a surge in demand for efficient and innovative products. Consumer preferences are evolving, driven by a combination of health consciousness, convenience, and technological advancements. Here’s a closer look at the current market trends and how they shape consumer preferences in the kitchen appliance industry.

Health and Wellness Take Center StageOne of the most significant trends in the kitchen appliance market is a growing emphasis on health and wellness. Consumers are increasingly looking for appliances that can help them prepare nutritious meals at home. This includes not just kitchen gadgets for cooking, but also those that can assist in meal planning and portion control. For instance, sandwich presses that offer adjustable heat settings have become popular, allowing users to achieve a desired level of crispness without overcooking their ingredients.

Smart Technology IntegrationThe integration of smart technology in kitchen appliances is another major trend. Consumers are seeking appliances that can be controlled remotely, offering convenience and efficiency. Smart sandwich presses, for example, can be connected to a smartphone app, allowing users to monitor and control the cooking process from anywhere. This technology not only adds a layer of convenience but also ensures that the sandwich is perfectly toasted, even when the user is not in the kitchen.

Sustainability and Eco-Friendly DesignsWith environmental concerns on the rise, there’s a strong preference for sustainable and eco-friendly kitchen appliances. Consumers are looking for products that are energy-efficient and made from recyclable materials. The sandwich press market has responded by offering models that are designed with the environment in mind, featuring energy-saving modes and components that are easy to recycle.

Design Aesthetics and FunctionalityThe aesthetic appeal of kitchen appliances has become a key factor in consumer decisions. Modern consumers not only seek appliances that perform well but also those that complement their kitchen’s decor. Sandwich presses are now available in a variety of sleek designs, including brushed stainless steel, black, and even colorful finishes. The emphasis on both form and function means that these appliances are not just tools for cooking but also stylish additions to the kitchen.

Customization and PersonalizationPersonalization has become a significant trend in the kitchen appliance market. Consumers are looking for appliances that can be tailored to their specific needs and preferences. This includes features like adjustable heat settings, non-stick surfaces for easy cleaning, and even sandwich presses with interchangeable plates for different types of bread. The ability to customize the cooking experience is appealing to those who want to have more control over their meals.

Versatility in FunctionThe versatility of kitchen appliances is highly valued by today’s consumers. A sandwich press that can also toast bagels, make paninis, or even grill vegetables is seen as a smart investment. The demand for multi-functional appliances is driven by the desire for convenience and the ability to prepare a variety of dishes with a single tool.

E-commerce InfluenceThe rise of e-commerce has also had a profound impact on consumer preferences. Online shopping allows consumers to compare products, read reviews, and make informed decisions. The convenience of shopping from home and the ease of finding niche products have changed how consumers approach kitchen appliance purchases.

The trend towards healthy eating, smart technology, sustainability, design, customization, versatility, and e-commerce all play a role in shaping consumer preferences in the kitchen appliance market. As manufacturers continue to innovate, these trends will likely evolve, offering consumers even more options to meet their unique needs and preferences.

In the bustling landscape of commercial kitchens, the National Sanitation Foundation (NSF) plays a pivotal role in ensuring that the equipment used meets stringent safety and health standards. The organization’s seal of approval is not just a certification; it’s a benchmark that speaks volumes about the reliability and quality of kitchen equipment, including sandwich presses.

The NSF’s involvement in the commercial kitchen equipment sector is multifaceted. It starts with the development of rigorous standards that manufacturers must adhere to. These standards are designed to protect public health and safety, ensuring that the equipment is not only functional but also safe to use.

One of the key aspects of NSF’s role is the testing and certification process. Equipment manufacturers must submit their products for thorough evaluation, which includes material safety tests, performance assessments, and user safety checks. This process ensures that the sandwich press, for instance, not only delivers a perfect sandwich but also does so without the risk of harmful chemical leaching or the potential for user injury.

The NSF certification also addresses the longevity and sustainability of the equipment. It assesses the durability of components, the efficiency of energy use, and the recyclability of materials. This is particularly important for sandwich presses, which are used extensively in high-volume environments where equipment wear and tear can be rapid.

Moreover, NSF standards consider the ease of maintenance and cleaning, which is crucial for maintaining a hygienic kitchen. A sandwich press that is easy to clean not only reduces the risk of foodborne illness but also streamlines the kitchen workflow, allowing for more efficient service.

In the realm of energy efficiency, NSF-approved sandwich presses are likely to be equipped with features that minimize energy consumption. This is not just a cost-saving measure for businesses but also a responsible step towards environmental sustainability. In an industry where energy use can be significant, such innovations are highly valued.

The NSF also keeps a pulse on industry trends and updates its standards accordingly. This adaptability ensures that the certification remains relevant and continues to serve as a mark of excellence. For example, with the growing emphasis on food safety and traceability, NSF may update its guidelines to reflect these new requirements.

For operators of commercial kitchens, the NSF approval is a reassurance. It means that the sandwich press, along with other kitchen equipment, has been vetted by an independent third party. This can be a significant differentiator when attracting customers who are increasingly health-conscious and seek out establishments that prioritize cleanliness and safety.

In terms of regulatory compliance, the NSF certification can also help businesses avoid legal pitfalls. By using NSF-approved equipment, kitchens are more likely to meet local and federal health codes, reducing the risk of fines or closures.

Furthermore, the NSF’s involvement in the training and education of kitchen staff is another critical aspect of its role. By promoting proper usage and maintenance of kitchen equipment, the NSF helps to prevent accidents and ensure that staff are well-equipped to handle the latest in commercial kitchen technology.

The impact of NSF certification extends beyond the immediate product. It influences the entire supply chain, pushing manufacturers to innovate and improve their products. This, in turn, can lead to a ripple effect that benefits the entire industry, from the manufacturer to the end consumer.

In conclusion, the NSF’s role in the commercial kitchen equipment sector is integral to maintaining high standards of safety, health, and efficiency. For the sandwich press, NSF approval signifies a commitment to excellence that extends from the material selection to the user experience, making it a trusted choice for kitchens worldwide.

In one busy café, the introduction of an NSF-approved sandwich press transformed the daily workflow. This sleek, commercial-grade appliance not only streamlined the process of pressing out perfect sandwiches but also became a standout feature for customers. The press’s even heating and pressure capabilities meant every sandwich was consistently cooked to perfection, a stark contrast to the inconsistent results achieved with previous methods.

At a bustling deli, the adoption of an NSF-certified sandwich press marked a significant shift in their menu offerings. They were able to introduce a variety of new sandwich options, including gluten-free and vegan selections, thanks to the press’s versatile design. This expanded menu not only catered to a wider range of dietary preferences but also increased their customer base significantly.

A high-end hotel’s catering department found that the implementation of an NSF-approved sandwich press elevated their event offerings. The press’s ability to create professional-quality sandwiches in large quantities without compromising on quality was invaluable for large-scale events. The uniformity and consistency of the sandwiches left a lasting impression on guests, reflecting the hotel’s commitment to excellence in service.

In a fast-casual restaurant, the sandwich press became a cornerstone of their sandwich-making process. The speed at which the press could cook and seal sandwiches meant faster service times for their customers. The increased efficiency also allowed the kitchen staff to handle more orders without sacrificing the quality of the food. This efficiency boost translated into higher customer satisfaction and improved overall sales.

A health-conscious café integrated an NSF-approved sandwich press into their kitchen to offer a range of low-fat and high-protein sandwiches. The press’s ability to cook with minimal oil made it an ideal choice for their health-focused menu. The sandwiches were not only healthier but also retained their moisture and flavor, a testament to the press’s superior cooking capabilities.

In a sports stadium, the addition of an NSF-approved sandwich press to the concessions area was a game-changer. It allowed for quick, on-the-go sandwiches that were both satisfying and nutritious. The press’s durability and ease of use ensured that it could withstand the rigorous demands of a high-traffic environment, providing consistent results throughout the event.

A local food truck business found that the NSF-certified sandwich press was a perfect fit for their mobile kitchen. The compact size and portability of the press meant they could offer their signature sandwiches at various locations without any hassle. The press’s reliability and ease of cleaning were key factors in maintaining the cleanliness and safety standards of their mobile kitchen.

A school cafeteria replaced their outdated sandwich presses with NSF-approved models to improve the quality of their meals. The new presses were not only more efficient but also easier to use, reducing the time spent on lunch preparation. The school’s students and staff appreciated the improved taste and texture of the sandwiches, making the cafeteria a more popular spot during mealtime.

A gourmet bakery used an NSF-approved sandwich press to experiment with unique flavors and textures in their sandwiches. The press’s even heat distribution allowed for precise cooking, enabling the bakery to create sandwiches with perfect grill marks and melted cheese. This addition to their menu became a hit, offering a unique twist on the traditional sandwich.

In a community kitchen that serves a diverse group of people, the NSF-certified sandwich press was a unifying tool. It allowed the kitchen staff to cater to various dietary needs, from vegetarian to keto, with ease. The consistency and quality of the sandwiches were well-received by everyone, fostering a sense of community and inclusivity through shared meals.

Understanding the needs of your kitchen, the capacity of your staff, and the demands of your customers are key factors in selecting the perfect NSF approved sandwich press for your business. Here’s a breakdown of what to consider:

Assess Your Kitchen SpaceBefore diving into the specifics of the sandwich press, consider the physical space you have available. Is there room for a large, countertop model, or do you need a compact, undercounter unit? The layout of your kitchen will greatly influence the type of press that will fit seamlessly into your workflow.

Evaluate Your MenuThe variety of sandwiches you offer should guide your choice of press. If you’re specializing in artisanal sandwiches with thick bread, you might need a press with adjustable pressure to ensure even cooking. Conversely, if your menu is more about quick service, a model with a simple on/off feature might suffice.

Consider Capacity and SpeedThe volume of sandwiches you plan to produce daily is crucial. A high-capacity press can handle more batches in less time, which is ideal for busy cafes and delis. Look for features like programmable settings that can accommodate different types of bread and fillings, allowing for quick adjustments without sacrificing quality.

Durability and MaintenanceInvesting in a durable sandwich press is essential for long-term success. Look for models made from high-quality materials that can withstand the rigors of a commercial kitchen. Also, consider the ease of cleaning and maintenance. A press that’s easy to disassemble and clean can save time and reduce the risk of cross-contamination.

Safety FeaturesSafety should always be a top priority in a commercial kitchen. Ensure that the NSF approved sandwich press you choose has safety features like non-slip feet, cool-to-the-touch exteriors, and emergency stop mechanisms. These features not only protect your staff but also prevent accidents and ensure compliance with health codes.

Energy EfficiencyEnergy costs can add up, especially in a busy kitchen. Opt for a sandwich press that is energy-efficient, as it can help reduce your utility bills over time. Look for models with automatic shut-off features that turn off the press after a certain period of inactivity.

Brand Reputation and WarrantyThe reputation of the manufacturer can be a good indicator of the quality of the sandwich press. Brands with a strong presence in the commercial kitchen equipment market often stand behind their products with robust warranties. A good warranty can provide peace of mind and protect your investment.

Customer FeedbackBefore making a final decision, read reviews and gather feedback from other businesses that have purchased similar sandwich presses. Real-world experiences can offer valuable insights into the performance and reliability of the equipment.

Budget ConsiderationsFinally, align your budget with your needs. While it’s tempting to go for the most expensive model, it’s important to find the right balance between cost and quality. A well-priced NSF approved sandwich press can offer excellent performance without breaking the bank.

Future-ProofingThink about the scalability of your business. A sandwich press that can adapt to future menu changes or increased demand can be a wise investment. Choose a model that allows for potential upgrades or modifications as your business grows.

By carefully considering these factors, you can select an NSF approved sandwich press that not only meets your current needs but also has the flexibility to support the growth and success of your business.

The evolution of sandwich presses has been marked by a constant push for efficiency, convenience, and innovation. As the demand for high-quality, quick-service food options grows, the future of sandwich press technology is poised to revolutionize the way we think about fast-casual dining. Here are some key trends and predictions that are shaping the future of sandwich press technology.

Smart Automation: The integration of smart technology into sandwich presses is already gaining traction. Imagine a press that not only ensures consistent results but also communicates with the kitchen staff to optimize workflow and reduce downtime. Features like automated temperature control, pressure adjustment, and even predictive maintenance could become standard.

Customization on Demand: With the rise of personalized food experiences, sandwich presses are likely to evolve to accommodate a wider variety of ingredients and cooking styles. Multi-functional presses that can handle everything from paninis to avocado toast to grilled cheese are on the horizon, allowing for on-the-spot customization without compromising on speed or quality.

Energy Efficiency: As sustainability becomes a more critical concern, the next generation of sandwich presses will likely focus on energy efficiency. Smaller footprints, energy-saving modes, and the use of eco-friendly materials are just a few ways that manufacturers are expected to reduce the environmental impact of their products.

Health and Safety: The future of sandwich press technology will undoubtedly emphasize health and safety features. From non-stick surfaces that reduce the need for chemical coatings to anti-microbial materials that prevent the growth of bacteria, the focus will be on creating a safer environment for both customers and staff.

Connectivity: Just as smartphones and kitchen appliances are becoming more connected, sandwich presses may soon be part of a larger kitchen ecosystem. They could be integrated with POS systems, inventory management software, and even customer-facing applications to provide a seamless experience from order to delivery.

Compact Design: The need for space-saving solutions in commercial kitchens is undeniable. As such, the design of sandwich presses is expected to become more compact without sacrificing performance. This trend could lead to the development of modular presses that can be easily expanded or reconfigured to fit any kitchen layout.

Enhanced Cooking Technology: Advances in cooking technology will likely lead to sandwich presses that offer more precise control over cooking times and temperatures. This could mean faster cooking cycles, better texture retention, and the ability to cook a variety of foods without the need for additional cooking equipment.

Smart Cooking Profiles: With the help of AI and machine learning, sandwich presses could offer personalized cooking profiles based on user preferences and ingredient combinations. This would not only streamline the cooking process but also ensure that every sandwich is cooked to perfection.

Eco-Friendly Materials: The use of sustainable materials in sandwich press construction is becoming increasingly important. From recycled metals to biodegradable plastics, the industry is moving towards a more environmentally responsible approach to product design.

User-Friendly Interface: As technology becomes more sophisticated, the interfaces on sandwich presses will need to be more intuitive. A user-friendly interface that allows for easy adjustments and programming will be crucial for busy kitchen staff who need to maintain efficiency without the need for extensive training.

In conclusion, the future of sandwich press technology is bright, with a focus on automation, customization, sustainability, and user experience. As the demand for high-quality, quick-service food continues to grow, these innovations will be key to meeting the needs of modern kitchens and satisfying the palates of discerning consumers.

The NSF-approved commercial sandwich press has emerged as a game-changer in the foodservice industry. By understanding the impact of this certification, businesses can gain insight into the quality and safety of their equipment. Here’s how the NSF approval not only ensures compliance but also enhances the operational excellence of commercial kitchen equipment.

In today’s fast-paced restaurant environment, where time is of the essence, the efficiency of kitchen appliances is paramount. The NSF certification serves as a testament to the reliability and performance of commercial sandwich presses. These units are designed to meet stringent standards for food safety, cleanliness, and durability, making them a reliable choice for busy kitchens.

The design of an NSF-approved sandwich press is not just about pressing sandwiches to perfection; it’s about incorporating innovations that cater to the evolving needs of the industry. Modern presses feature non-stick surfaces that prevent food from sticking, ensuring consistent and clean results with every press. Additionally, the ability to adjust heat settings and cooking times allows for versatility in preparing a variety of sandwich options, from classic ham and cheese to gourmet creations with exotic fillings.

Hygiene is a critical factor in foodservice operations, and NSF-approved sandwich presses address this concern head-on. The materials used in these presses are resistant to corrosion and easy to clean, which is essential for maintaining a clean kitchen environment. Features like removable drip trays and sealed components prevent the spread of bacteria and ensure that every sandwich is cooked with the highest level of sanitation.

Market trends indicate a growing preference for convenience and speed in food preparation. Consumers are increasingly looking for quick-service options that don’t compromise on quality. The NSF-approved sandwich press has capitalized on this trend by delivering high-quality sandwiches in record time. The demand for such appliances is likely to rise as more businesses seek to attract time-conscious diners.

The integration of technology into kitchen equipment is another significant trend. While the traditional sandwich press has been a staple in the industry for decades, new models now come with digital controls that allow for precise temperature and timing. These advancements not only enhance the cooking experience but also provide operators with data that can optimize their workflows.

For businesses looking to implement an NSF-approved sandwich press, there are several factors to consider. The size of the operation will dictate the capacity and size of the press needed. Some models are designed for high-volume restaurants, while others are better suited for smaller cafes or delis. Additionally, the type of sandwiches you plan to serve will influence the features you should look for, such as adjustable heat settings or a flat surface for a variety of fillings.

The future of sandwich press technology is poised to bring even more innovation to the forefront. Smart presses could be on the horizon, with built-in sensors that adjust to the type of sandwich being prepared, ensuring consistent results every time. These advancements may also include predictive maintenance features that alert operators to potential issues before they become problematic.

As for the role of NSF in commercial kitchen equipment, it serves as a guiding light for businesses looking to invest in quality. NSF International is a recognized leader in public health and safety, offering certification programs that ensure products meet strict criteria. For equipment like the sandwich press, this certification means that it has been evaluated for its performance, material safety, and cleanliness, providing peace of mind for operators and consumers alike.

In conclusion, the NSF-approved commercial sandwich press is more than just a kitchen appliance; it’s a symbol of quality, safety, and innovation. By embracing these standards, businesses can not only elevate their sandwich offerings but also set a new benchmark for foodservice excellence. With continuous advancements in technology and design, the sandwich press is set to remain a staple in commercial kitchens, constantly improving to meet the demands of a modern, health-conscious consumer.