Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In the ever-evolving landscape of kitchen appliances, there’s a buzz around a new trend that’s reshaping the way we think about our kitchens. It’s not just about the latest gadgets or sleek designs; it’s about the intersection of innovation and sustainability. This article delves into the fascinating world of integrated metal stamping for sandwich plates, exploring how this technology is not only revolutionizing the kitchen appliance industry but also paving the way for a greener, more efficient future. Join us as we uncover the latest market trends, consumer insights, and the expert opinions that are shaping this dynamic field.

The kitchen has always been the heart of the home, a place where culinary magic happens and memories are made. In recent years, there’s been a significant shift in kitchen trends, with one particular innovation standing out: the sandwich plate. Once a simple, functional piece of kitchenware, the sandwich plate has evolved into a must-have item for modern kitchens. Let’s delve into the reasons behind this surge in popularity.

Gone are the days when a sandwich plate was just a flat, round dish for serving cold cuts. Today, these plates are not just for sandwiches anymore; they’ve become a versatile tool for both casual and gourmet meals. The rise of the sandwich plate can be attributed to several factors, starting with the increasing demand for convenience in our fast-paced lives.

With busy schedules and the rise of single-person households, the need for quick and easy meal options has never been greater. Sandwich plates offer a perfect solution, allowing individuals to create a variety of meals in mere minutes. From a quick lunch of turkey and cheese to a sophisticated dinner with layers of flavors, these plates are a kitchen staple that caters to diverse tastes and dietary preferences.

Moreover, the sandwich plate’s adaptability is a game-changer. They’re not just for sandwiches; they can be used to serve salads, appetizers, and even desserts. The flat surface provides ample space for a variety of ingredients, while the raised edges prevent spills and make cleanup a breeze. This versatility has made sandwich plates a favorite among both homeowners and chefs alike.

Another reason for the sandwich plate’s rise is the influence of social media and food blogs. With the rise of influencers and food enthusiasts sharing their culinary creations online, there’s a constant stream of inspiration for home cooks. Sandwich plates have become a favorite prop for showcasing these creative dishes, further boosting their popularity.

Design-wise, sandwich plates have also seen a remarkable transformation. No longer limited to the traditional round shape, these plates now come in a variety of shapes, sizes, and materials. From sleek, minimalist designs to ornate patterns and vibrant colors, there’s a sandwich plate to match every kitchen aesthetic. This variety has allowed sandwich plates to appeal to a broader audience, from minimalist decorators to those who prefer a more eclectic look.

The integration of technology into kitchenware has also played a role in the sandwich plate’s popularity. Smart sandwich plates are now available, featuring built-in temperature controls and timers, making it easier than ever to ensure that your meal is perfectly toasted or heated. These innovative features not only enhance the user experience but also add a touch of modernity to the kitchen.

In addition to convenience and design, sustainability has become a key concern for many consumers. The sandwich plate’s eco-friendly production process, which often involves recycled materials, has made it an attractive choice for environmentally conscious shoppers. As people become more aware of their carbon footprint, they’re seeking out products that align with their values, and the sandwich plate fits the bill.

The rise of the sandwich plate in modern kitchens is also a testament to the power of innovation. As manufacturers continue to push the boundaries of what’s possible, we can expect to see even more exciting developments in this area. From new materials to advanced features, the future of sandwich plates looks bright.

In conclusion, the sandwich plate has transcended its humble origins to become a symbol of modern convenience, design, and sustainability. As our lives become increasingly fast-paced and diverse, the sandwich plate stands as a versatile and stylish solution that caters to the needs of today’s kitchen. Whether you’re a busy professional, a foodie, or simply someone who appreciates a good meal, the sandwich plate is undoubtedly here to stay.

Integrated metal stamping has emerged as a pivotal technology in various industries, particularly in the manufacturing of kitchen appliances. This process involves the creation of precision-formed metal parts by the use of dies and presses, allowing for the production of complex shapes with high accuracy and efficiency. Here’s a deeper look into the role of integrated metal stamping:

The precision and consistency of stamped parts are unmatched in the industry. Each stamping operation is meticulously controlled to ensure that every component meets the exact specifications required. This level of precision is crucial in kitchen appliances, where components must fit perfectly to ensure functionality and safety.

Efficiency is a cornerstone of integrated metal stamping. The process is highly automated, reducing the need for manual labor and streamlining production. This not only cuts down on costs but also shortens lead times, allowing manufacturers to respond quickly to market demands and consumer trends.

Customization is another key advantage of metal stamping. While mass production is its forte, the technology can be adapted to create a wide range of custom parts, making it ideal for kitchen appliances that often require unique components to meet specific design or functional requirements.

The durability of stamped parts is a significant factor in the longevity of kitchen appliances. Metal stamping produces parts that are strong and resistant to wear, ensuring that the appliances can withstand the rigors of daily use in a kitchen environment.

Innovation is fostered through the use of integrated metal stamping. The ability to create intricate shapes and combine multiple parts into a single assembly opens up new possibilities for design and functionality. This has led to the development of more efficient and user-friendly kitchen appliances.

The cost-effectiveness of metal stamping cannot be overstated. By reducing the need for additional assembly and finishing operations, the overall production cost is significantly lower. This cost savings can be passed on to consumers, making high-quality kitchen appliances more accessible.

Environmental considerations are increasingly important in manufacturing, and integrated metal stamping contributes positively to sustainability efforts. The process uses less material than traditional methods, reducing waste. Additionally, the efficiency of the stamping process means less energy is consumed, further reducing the carbon footprint.

The scalability of metal stamping is a major benefit. Whether producing a few units for a niche market or millions for a mass-market product, the stamping process can be easily adjusted to accommodate different production volumes without compromising quality.

Quality control is integrated into the metal stamping process from start to finish. The use of advanced inspection equipment and rigorous quality checks at each stage ensures that only the highest-quality parts leave the factory floor.

The versatility of metal stamping is evident in the wide range of materials that can be used, from mild steel to stainless steel, aluminum, and copper. This flexibility allows manufacturers to choose the right material for the specific requirements of each kitchen appliance component.

The integration of metal stamping into the manufacturing process also contributes to the overall design flexibility. Engineers can design components that are both aesthetically pleasing and highly functional, enhancing the user experience.

The longevity of the stamping tools themselves is impressive. Properly maintained dies can last for years, providing a consistent supply of high-quality parts over an extended period.

In conclusion, integrated metal stamping plays a multifaceted role in the kitchen appliance industry. Its precision, efficiency, customization, durability, cost-effectiveness, environmental friendliness, scalability, quality control, versatility, design flexibility, and tool longevity all contribute to its central role in the production of modern kitchen appliances.

In the ever-evolving landscape of kitchen appliances, sandwich plates have emerged as a game-changer, offering functionality and style. With the integration of metal stamping technology, these plates have seen a wave of innovations that are reshaping the way we think about kitchenware. Here’s a closer look at some of the most notable advancements.

The Art of Design Meets DurabilityMetal stamping has allowed for the creation of sandwich plates with intricate designs and patterns that were once impossible to achieve with traditional manufacturing methods. The process involves forming metal sheets into precise shapes, which can result in plates that are not only visually appealing but also incredibly durable, able to withstand the rigors of daily kitchen use.

Sleek and Sophisticated AestheticsOne of the standout features of sandwich plates crafted through metal stamping is their sleek and sophisticated appearance. The ability to create fine details and metallic textures adds a level of elegance to kitchen countertops. Whether it’s a brushed finish or a polished look, these plates bring a touch of luxury to the everyday cooking experience.

Customization Like Never BeforeMetal stamping opens up a world of customization possibilities for sandwich plates. Manufacturers can now produce plates in a wide array of shapes, sizes, and designs, catering to the unique tastes of consumers. From minimalist geometric patterns to intricate floral motifs, the options are virtually limitless, allowing homeowners to express their personal style in their kitchen.

Improved Heat Distribution and RetentionThe innovative design of sandwich plates with integrated metal stamping often includes hollowed-out or layered structures. This not only adds to the aesthetic appeal but also improves the plate’s thermal properties. The hollow spaces can enhance heat distribution, ensuring that food is cooked evenly, while the layered design can help retain heat, keeping meals warmer for longer periods.

Enhanced Safety FeaturesSafety is a top priority in kitchen appliances, and metal stamping technology has contributed to this aspect as well. The ability to create non-slip surfaces and heat-resistant edges through stamping ensures that sandwich plates are safer to use. This is particularly important when serving hot dishes, as the risk of burns is significantly reduced.

Efficiency in Production and SustainabilityThe efficiency of metal stamping in the production of sandwich plates cannot be overstated. This method allows for high-speed and high-volume manufacturing, which reduces waste and energy consumption. As a result, manufacturers can produce more plates with less environmental impact, aligning with the growing demand for sustainable kitchenware.

Innovative Cooking TechniquesSandwich plates with integrated metal stamping have also paved the way for new cooking techniques. The unique designs of these plates can be used to create sous-vide-style cooking, where food is vacuum-sealed and then cooked in a water bath at a precise temperature. This not only locks in flavors but also ensures food is cooked to perfection.

Versatility in UseThe versatility of sandwich plates with metal stamping is another innovation that has gained traction. These plates can be used for a variety of purposes, from serving salads and appetizers to cooking steaks and vegetables. The durable construction and diverse designs make them suitable for both casual dining and formal gatherings.

Ease of CleaningOne of the practical benefits of metal-stamped sandwich plates is their ease of cleaning. The smooth, non-porous surfaces are resistant to stains and are simple to wipe clean, saving time and effort for busy cooks. This feature is particularly appealing to those who value convenience without compromising on quality.

In conclusion, the integration of metal stamping into sandwich plates has revolutionized the kitchenware industry. From aesthetic improvements to functional enhancements, these plates have become a symbol of modern kitchen innovation. As technology continues to advance, we can expect even more exciting developments that will further elevate the role of sandwich plates in our daily lives.

The kitchen landscape is undergoing a transformation, with a growing emphasis on efficiency, convenience, and sustainability. Consumers are increasingly seeking appliances that not only streamline their cooking routines but also enhance the overall kitchen experience. Here’s a closer look at the current market trends and consumer insights shaping the world of kitchen appliances.

In the realm of kitchen appliances, the demand for smart technology is on the rise. Consumers are looking for devices that can be controlled remotely, offering convenience and the ability to manage kitchen tasks from anywhere. Smart ovens, refrigerators with Wi-Fi capabilities, and even smart cooktops are becoming more common, reflecting a shift towards technology integration in everyday life.

The kitchen has traditionally been a hub for family gatherings and meals. As such, appliances that encourage social interaction are gaining popularity. Large, communal cooking surfaces and kitchen islands that double as prep stations are becoming more prevalent. These features not only cater to the need for shared cooking experiences but also to the desire for open, versatile kitchen spaces.

Energy efficiency is no longer just a concern for the environmentally conscious; it’s a mainstream expectation. Consumers are gravitating towards appliances that have a lower energy footprint. Energy-saving labels and certifications are becoming more important, as they signal to buyers that a product is both cost-effective and eco-friendly.

Sustainability is not just about energy use; it’s about the entire lifecycle of the product. There’s a growing preference for appliances made from recycled materials and designed for longevity. This extends to the packaging as well, with more brands opting for recyclable or biodegradable materials to minimize waste.

Innovation in design is also a key driver in the kitchen appliance market. Sleek, minimalist aesthetics are in vogue, but so are unique and functional designs that offer a touch of personality to the kitchen. Consumers are looking for appliances that not only look good but also offer a seamless blend with their kitchen decor.

Customization is becoming a significant trend, allowing consumers to choose appliances that fit their specific needs and preferences. From color options to unique features, appliances that can be tailored to individual tastes are becoming more common. This reflects a shift towards personalization in all aspects of life, including the kitchen.

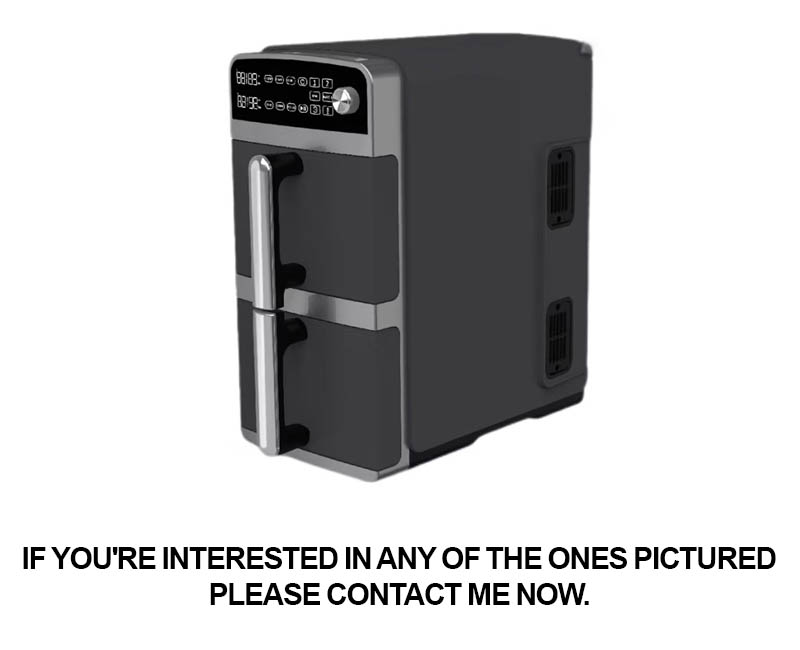

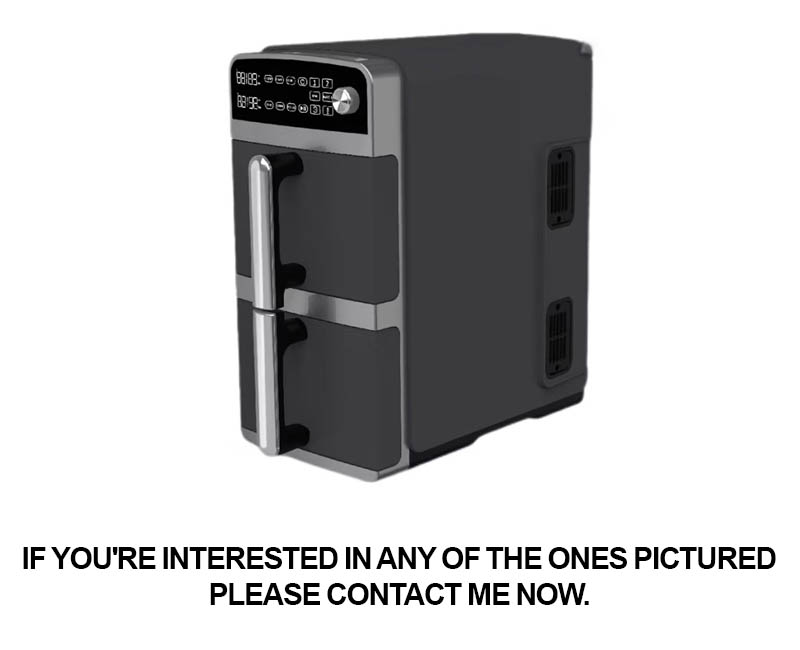

Health and wellness are at the forefront of consumer minds, and this extends to kitchen appliances. There’s a growing interest in appliances that make cooking healthier, such as air fryers and steam ovens that offer healthier alternatives to traditional frying and baking methods. Consumers are also looking for appliances that can help them track and manage their dietary needs, such as smart scales and calorie-counting appliances.

Safety features are becoming more sophisticated, with a focus on preventing accidents and protecting users. From child-proof locks on ovens to automatic shut-offs in case of overheating, safety is a key consideration for today’s consumers. Appliances that offer peace of mind are likely to resonate with buyers who prioritize security in their homes.

Finally, the rise of social media and online reviews has had a profound impact on consumer behavior. Consumers are more likely to make purchases based on the experiences and recommendations of others. This means that brands must not only deliver quality products but also engage with consumers through storytelling and community building.

The kitchen appliance market is evolving rapidly, influenced by a combination of technological advancements, changing consumer values, and shifting lifestyle trends. By understanding these market trends and consumer insights, appliance manufacturers can better meet the needs and desires of their customers, ensuring a bright future for the industry.

In the world of kitchen appliances, industry experts are a treasure trove of insights and predictions. Their perspectives shed light on the direction the market is heading, and their analysis often reveals the pulse of consumer needs and expectations. Here’s a glimpse into what these experts have to say:

The Shift Towards Smart Kitchen AppliancesIndustry experts are noting a significant shift towards smart kitchen appliances, with a particular emphasis on those featuring integrated metal stamping for sandwich plates. This trend is driven by the consumer desire for convenience, efficiency, and technology integration in their daily lives.

Innovation in Materials and DesignExperts agree that there’s a growing emphasis on innovation in both materials and design. The use of advanced metal stamping techniques for sandwich plates allows for not just durability but also the creation of intricate and functional designs that cater to modern aesthetic tastes.

Energy Efficiency and SustainabilityEnergy efficiency and sustainability are at the forefront of discussions among industry experts. They highlight that the demand for eco-friendly appliances, including those made with recycled metals from stamping processes, is not just a trend but a necessity for the future of the kitchen appliance industry.

The Role of E-commerceE-commerce’s impact on kitchen appliances is undeniable. Experts point out that the rise of online shopping has changed how consumers interact with brands and how they discover new products. This shift has also influenced the design and marketing strategies of appliance manufacturers.

Consumer Preferences and BehaviorUnderstanding consumer preferences and behavior is critical in the appliance industry. Experts discuss how consumers are increasingly looking for appliances that are easy to use, have a sleek design, and offer smart features. They emphasize the importance of intuitive interfaces and seamless integration with other smart devices in homes.

The Importance of Branding and StorytellingIn the competitive kitchen appliance market, branding and storytelling play a vital role. Experts note that companies that effectively communicate their brand values and product benefits are more likely to resonate with consumers. They suggest that the narrative around appliances, including sandwich plates, should highlight how they enhance the quality of life.

Global Market DynamicsIndustry experts also discuss the global market dynamics, noting that while North America and Europe remain strong markets, there is a surge of interest in emerging markets like Asia and Latin America. These regions are showing a high demand for affordable yet high-quality appliances.

Regulatory Compliance and Safety StandardsCompliance with regulatory standards and safety is non-negotiable. Experts stress that adherence to these standards not only ensures consumer safety but also builds trust and credibility with consumers. They highlight the importance of certifications and quality control measures in the manufacturing process.

Future Innovations and ChallengesLooking ahead, industry experts anticipate several innovations and challenges. They predict a greater emphasis on energy-saving technologies, the use of more sustainable materials, and the integration of advanced functionalities such as voice control and AI. Challenges include navigating supply chain complexities and addressing consumer concerns about data privacy and security.

In conclusion, the insights from industry experts reveal a dynamic landscape in the kitchen appliance industry, particularly in the realm of sandwich plates made with integrated metal stamping. These experts emphasize the need for innovation, consumer-centric design, and adherence to high standards of quality and safety to meet the evolving demands of today’s consumers.

In the realm of kitchen appliances, there are several notable case studies that showcase successful implementations of innovative technologies. From compact kitchen gadgets to high-end appliances, these examples highlight the impact of cutting-edge solutions on consumer lifestyles.

In one such case, a leading manufacturer of kitchenware introduced a line of sandwich plates designed with integrated metal stamping. The plates were not only visually appealing but also featured a unique locking mechanism that ensured a tight seal, preventing any leakage. This innovation caught the attention of consumers who were looking for convenience and durability in their kitchenware.

Customers raved about the ease of use and the sleek design of the sandwich plates. The integrated metal stamping allowed for a seamless and robust construction, which was a significant upgrade from the traditional plastic or wooden alternatives. The manufacturer saw a surge in sales, with the product becoming a must-have for many households.

Another success story involves a small startup that focused on eco-friendly kitchen appliances. They developed a line of sandwich plates using recycled materials and integrated metal stamping to create lightweight yet sturdy products. The plates were not only sustainable but also offered a variety of functionalities, such as a built-in cooling system to keep sandwiches fresh.

The startup’s commitment to sustainability resonated with environmentally conscious consumers, leading to a strong market presence. The integrated metal stamping process enabled the company to produce plates that were both cost-effective and eco-friendly, making it a favorite among eco-conscious shoppers.

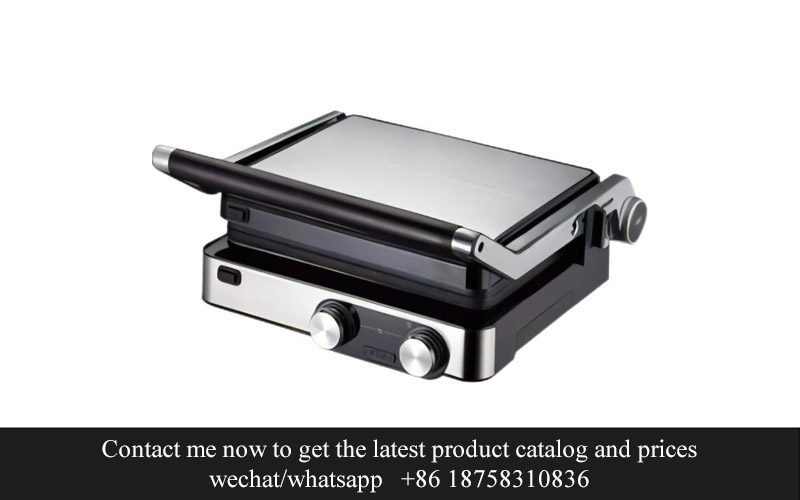

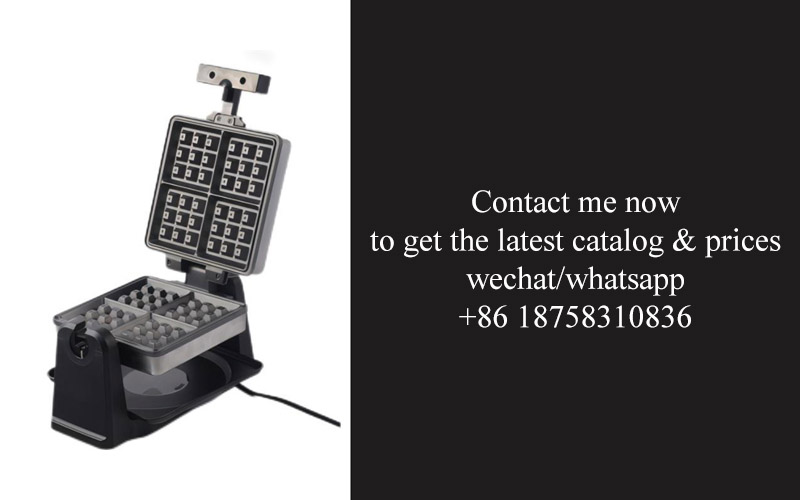

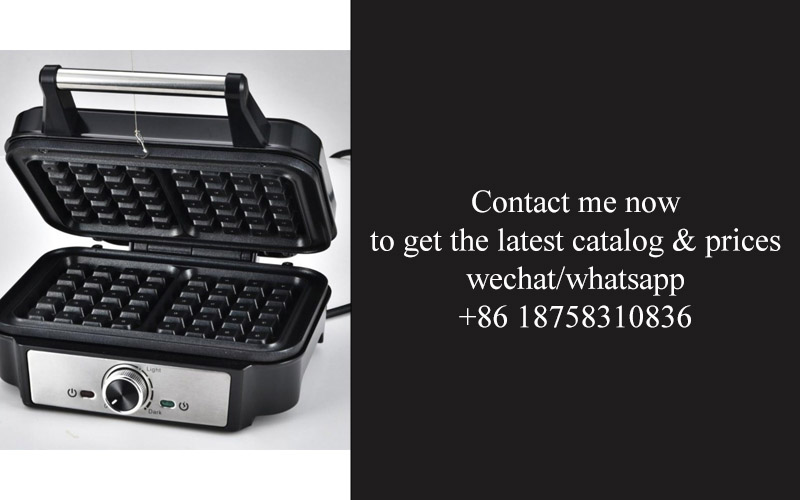

In a different sector, a global appliance brand incorporated integrated metal stamping into their high-end sandwich makers. The innovative design of the sandwich plates allowed for a faster cooking time and a more even distribution of heat. This resulted in perfectly toasted sandwiches every time, without the need for constant monitoring.

The success of this product can be attributed to the brand’s reputation for quality and innovation. The integrated metal stamping process not only enhanced the performance of the sandwich maker but also added an element of sophistication to the kitchen. Consumers were willing to invest in this premium appliance due to its seamless integration of technology and design.

A case study from a European kitchenware company demonstrated how integrated metal stamping could revolutionize the way people enjoy their morning coffee. They developed a line of coffee presses with sandwich plates that could be used for both brewing coffee and serving sandwiches. The innovative design allowed for a compact and multipurpose appliance that saved space in the kitchen.

The product quickly gained popularity due to its practicality and the convenience it offered to busy individuals. The integrated metal stamping process ensured that the sandwich plates were not only durable but also had a smooth surface that made them easy to clean. This attention to detail and functionality made the coffee press with sandwich plates a standout product in the market.

In the realm of commercial kitchen appliances, a fast-food chain implemented integrated metal stamping in their sandwich-making stations. The process allowed for the creation of custom sandwich plates that matched the brand’s aesthetic while ensuring a hygienic and efficient operation. The plates were designed to be stackable, reducing waste and making it easier for kitchen staff to manage the workflow.

The success of this implementation was twofold: it improved the overall quality of the sandwiches and enhanced the brand’s image. Customers appreciated the consistency and presentation of the sandwiches, while the fast-food chain enjoyed increased sales and customer satisfaction.

These case studies illustrate how integrated metal stamping has become a key factor in the development of innovative kitchen appliances. By combining functionality, durability, and aesthetic appeal, manufacturers are able to create products that not only meet consumer needs but also exceed their expectations. The future of kitchen appliances looks bright, with endless possibilities for further innovation through the use of integrated metal stamping technology.

In the quest for sustainable living, the environmental impact of products and manufacturing processes is under closer scrutiny than ever before. The environmental impact of sandwich plates, particularly those crafted through integrated metal stamping, is a topic of great interest. Here’s a closer look at how these factors interplay:

The Lifecycle of Sandwich PlatesFrom raw materials to disposal, the lifecycle of a sandwich plate is a complex web of environmental considerations. Metal stamping, as a manufacturing process, has evolved to minimize waste and reduce energy consumption, making it a more sustainable choice for producing sandwich plates.

Metal Stamping and Resource EfficiencyIntegrated metal stamping is a resource-efficient process that allows for the creation of sandwich plates with minimal material waste. The precision of stamping ensures that every piece of metal is utilized, which is a stark contrast to other manufacturing methods that may result in significant material losses.

Energy Consumption and EmissionsThe energy required to operate metal stamping machines has been significantly reduced over the years. Advanced technologies and energy-efficient motors are now standard, which not only lower operational costs but also decrease the carbon footprint associated with the production of sandwich plates.

Waste Reduction in Metal StampingOne of the key benefits of integrated metal stamping is the reduction of waste. By using precise cutting techniques and optimizing the design of sandwich plates, manufacturers can produce high-quality products with very little scrap. This waste is often recycled, further reducing the environmental impact.

Sustainable Materials and CoatingsIn addition to the manufacturing process, the choice of materials and coatings also plays a crucial role in the environmental impact of sandwich plates. Many manufacturers are now using recycled metals and eco-friendly coatings that are free from harmful chemicals, contributing to a more sustainable product lifecycle.

Recycling and End-of-Life DisposalThe end-of-life disposal of sandwich plates is another critical aspect of their environmental impact. Metal is one of the most recyclable materials, and when sandwich plates are made from metal, they can be easily recycled at the end of their useful life. This recycling process not only conserves resources but also reduces the need for new raw materials.

The Role of RegulationGovernment regulations and standards have also played a significant role in pushing the industry towards more sustainable practices. For example, restrictions on harmful substances in coatings and the promotion of energy-efficient manufacturing processes have spurred innovation in the metal stamping industry.

Consumer Awareness and DemandAs consumers become more environmentally conscious, there is a growing demand for sustainable products. This demand has influenced the design and production of sandwich plates, with manufacturers increasingly focusing on eco-friendly practices to meet consumer expectations.

Global Initiatives and CertificationsMany global initiatives and certifications, such as the ISO 14001 Environmental Management System, have been adopted by manufacturers to ensure that their products and processes adhere to stringent environmental standards. These certifications serve as a benchmark for the environmental impact of sandwich plates and other metal-stamped products.

Long-Term Sustainability GoalsThe metal stamping industry has set long-term sustainability goals that aim to reduce greenhouse gas emissions, minimize waste, and promote the use of renewable energy. These goals are being achieved through continuous improvements in technology, processes, and supply chain management.

Innovation in Metal Stamping TechniquesInnovation is a driving force behind the reduction of the environmental impact of sandwich plates. Advances in metal stamping techniques, such as the use of automation and advanced materials, are not only increasing efficiency but also reducing the environmental footprint of production.

The Impact of Remote ManufacturingThe rise of remote manufacturing, where products are produced closer to the consumer, is another trend that is reducing the environmental impact of sandwich plates. By minimizing transportation distances, the carbon footprint of these products is further decreased.

In conclusion, the environmental impact of sandwich plates, especially those produced through integrated metal stamping, is a multifaceted issue that encompasses the entire lifecycle of the product. From the choice of materials and manufacturing processes to end-of-life disposal, every step is being scrutinized and improved to ensure that sandwich plates are produced in a manner that is both sustainable and responsible.

Innovation has always been at the forefront of the kitchen appliances industry, and as we look towards the future, several trends are poised to shape the landscape of the next decade. From advancements in smart technology to sustainable manufacturing practices, here are some of the prospects that could redefine how we interact with our kitchen appliances.

The integration of artificial intelligence (AI) is expected to become more sophisticated, offering appliances that not only perform tasks but also learn from user habits to optimize performance and energy efficiency. Imagine a refrigerator that adjusts its cooling cycles based on the frequency of your grocery shopping or an oven that suggests recipes based on the ingredients you have on hand.

Sustainability is no longer just a buzzword; it’s a critical factor in product development. Companies are focusing on reducing the carbon footprint of their products throughout their lifecycle, from raw material sourcing to end-of-life recycling. This shift is prompting the development of appliances made from recycled materials, and the use of renewable energy sources in their production processes.

The Internet of Things (IoT) is expanding beyond smartphones and home security systems to include kitchen appliances. Smart kitchen ecosystems that allow users to control and monitor their appliances remotely are becoming more common. This interconnectedness promises greater convenience and efficiency, but also raises concerns about data security and privacy.

Health and wellness are increasingly influencing kitchen appliance design. We’re seeing a rise in appliances that not only enhance the taste and nutritional value of food but also make it easier to track and manage dietary intake. For example, juicers that provide detailed nutritional breakdowns or coffee makers that can tailor the strength and flavor of your brew based on your personal preferences.

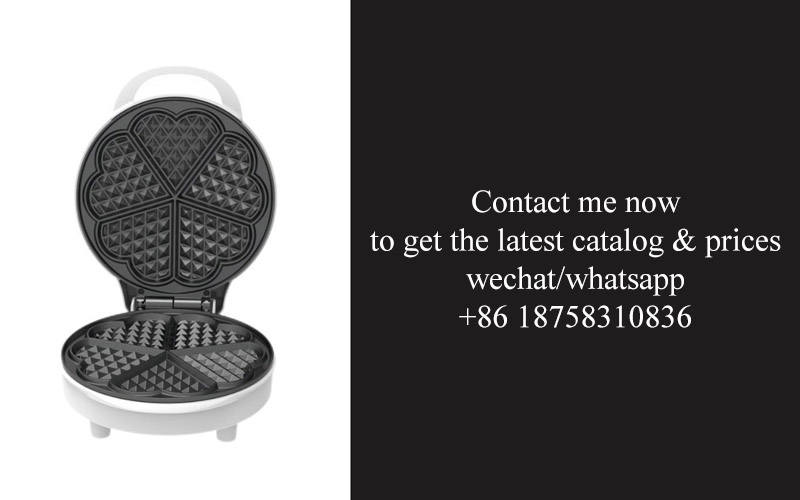

In the realm of cooking, there’s a growing interest in multi-functional appliances that can perform a variety of tasks. Induction cooktops that can switch between high and low heat quickly, air fryers that mimic the crispy texture of fried food with less oil, and countertop ovens that can handle a range of cooking techniques from baking to grilling are becoming popular.

The rise of personalization is also a significant trend. Appliances that can be customized to meet individual needs and preferences are gaining traction. This could mean appliances that come with a variety of interchangeable attachments or those that can be controlled via mobile apps to cater to specific cooking styles or dietary restrictions.

Energy efficiency remains a key concern, with manufacturers under pressure to produce appliances that consume less power while maintaining or improving performance. Innovations like LED lighting in refrigerators, energy-saving motors, and smart systems that adjust power usage based on usage patterns are becoming standard features.

In terms of design, appliances are becoming sleeker and more integrated into the kitchen’s overall aesthetic. There’s a move away from the clunky, boxy appliances of the past to sleek, modern designs that blend seamlessly with kitchen countertops and cabinets.

The rise of subscription-based models is another interesting development. Instead of purchasing appliances outright, consumers can subscribe to services that provide them with the latest appliances, often with maintenance and upgrade services included. This model is particularly appealing to those who prefer to avoid large upfront costs and want to always have the most advanced technology in their homes.

Lastly, there’s a growing emphasis on the importance of service and support. As appliances become more complex, the need for reliable customer service and technical support becomes paramount. Companies that invest in excellent after-sales service are likely to gain a competitive edge.

These future prospects are just the beginning. The kitchen appliances industry is continually evolving, and the next decade promises to bring even more innovations that will change the way we live, cook, and interact with our kitchen environments.

The journey through the world of kitchen appliances has been a fascinating one, marked by constant evolution and innovation. As we reflect on the journey, it’s clear that several key themes have emerged, shaping the direction of the industry.

Technology has been the driving force behind the latest advancements, with smart features becoming increasingly prevalent. From voice-controlled ovens to appliances that learn your cooking habits, technology is not just making kitchen tasks easier but also more personalized.

Sustainability has also taken center stage, with manufacturers focusing on eco-friendly materials and energy-efficient designs. This shift is not just a response to consumer demand but a recognition of the industry’s responsibility to the environment.

The integration of metal stamping technology, particularly in the creation of sandwich plates, has opened up new possibilities. The ability to craft intricate designs and durable components has not only enhanced the functionality of kitchen appliances but has also set new standards for aesthetics and reliability.

Consumer insights have been pivotal in guiding the development of these appliances. Understanding the needs and preferences of the modern consumer has led to a surge in multi-functional and user-friendly appliances that cater to a diverse range of lifestyles.

Industry experts have offered valuable perspectives, emphasizing the importance of innovation and the need to stay ahead of market trends. Their insights have underscored the fact that the future of kitchen appliances lies in a harmonious blend of technology, sustainability, and user-centric design.

Case studies of successful implementations have shown us that when these elements are brought together effectively, the results can be truly transformative. These examples serve as inspiration for what is possible when the industry embraces change and pushes boundaries.

As we look to the road ahead, it’s evident that future prospects are bright. The integration of advanced materials and technologies will continue to drive innovation. We can expect to see even more sophisticated appliances that not only simplify daily tasks but also enrich our lives.

The rise of smart kitchens, powered by the Internet of Things, promises a seamless integration of appliances, creating an environment where cooking and entertaining are more enjoyable and efficient. The potential for customization and personalization will also grow, allowing consumers to tailor their kitchen experiences to their unique tastes and needs.

Sustainability remains a critical focus, with manufacturers increasingly under pressure to reduce their environmental impact. This push will likely lead to more sustainable production processes, the use of renewable energy, and the development of appliances that are designed for longevity and easy recycling.

In conclusion, the kitchen appliance industry is at a pivotal point. The convergence of technology, sustainability, and consumer-centric design is propelling the industry forward. As we move forward, it’s important to remember that the success of these appliances is not just in their ability to perform tasks, but in how they enhance our lives and contribute to a healthier, more sustainable future. The journey is far from over, and the possibilities are vast.