Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In the ever-evolving culinary landscape, commercial air fryer factories are at the forefront of innovation, offering a healthier alternative to traditional frying methods. As the demand for quick, convenient, and nutritious food options grows, these factories are not only adapting to market trends but also pushing the boundaries of technology to meet the needs of modern kitchens. This article delves into the innovations shaping the commercial air fryer industry, the competitive landscape, and the future predictions that are reshaping the path forward for these factories.

Commercial air fryers have become a cornerstone in the culinary world, offering a healthier alternative to traditional deep-frying. These innovative appliances have not only reshaped the way we cook but have also revolutionized the commercial kitchen landscape. With their ability to deliver crispy, golden-brown results without the excess oil, commercial air fryers have captured the interest of chefs, restaurateurs, and health-conscious consumers alike.

The concept of air frying originated in the 1950s, with the invention of the first domestic air fryer. However, it wasn’t until the late 2000s that the technology gained traction in the commercial sector. Today, commercial air fryers are a staple in fast-casual restaurants, hotels, and even in the bustling kitchens of professional chefs. They are designed to handle higher volumes and more intense cooking conditions than their domestic counterparts, making them perfect for busy commercial environments.

One of the key advantages of commercial air fryers is their ability to significantly reduce fat content in fried foods. Traditional deep-frying involves submerging food in a large amount of hot oil, which leads to a high calorie count and unhealthy fats. In contrast, air fryers use a combination of hot air circulation and a small amount of oil to achieve a similar texture and flavor, with a fraction of the fat. This not only appeals to health-conscious consumers but also to operators looking to cut down on operational costs.

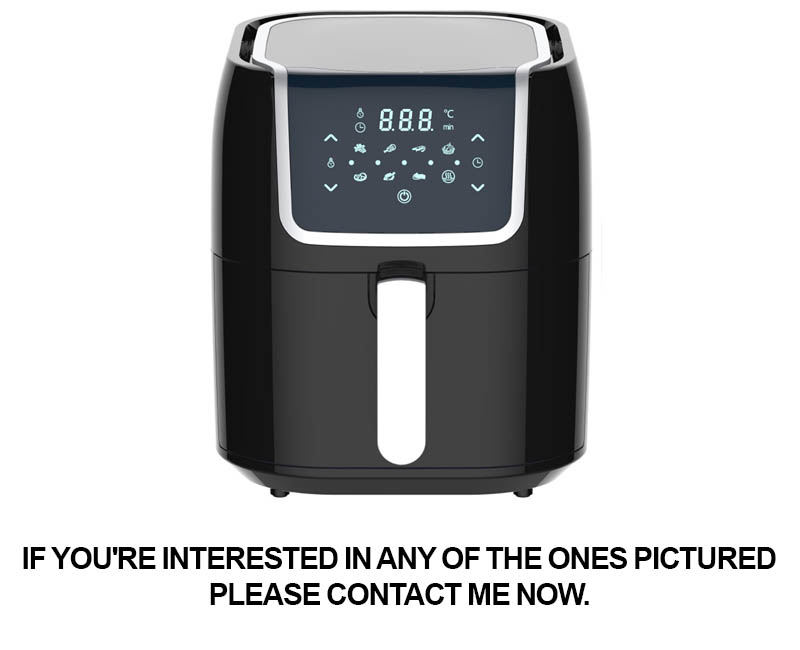

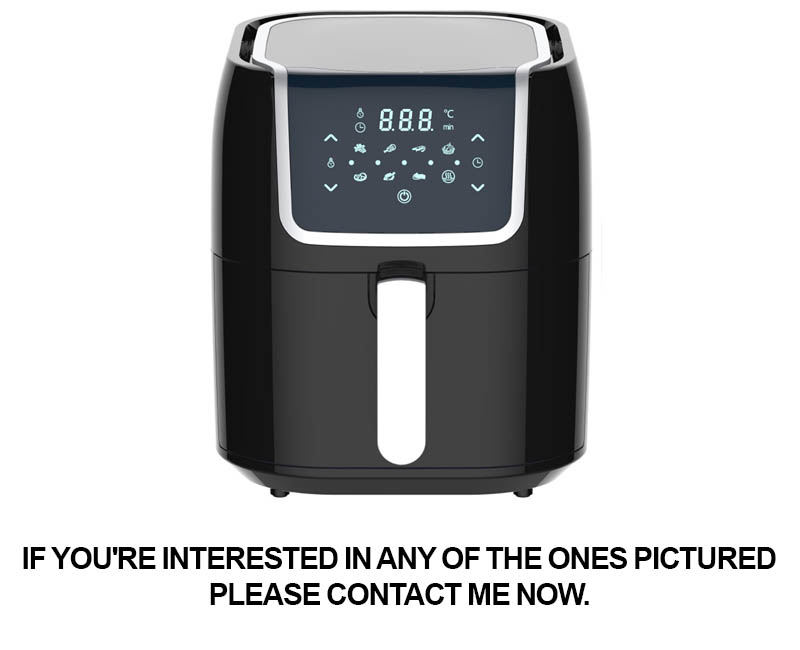

The design of commercial air fryers has also evolved to meet the demands of the modern kitchen. Many models now come equipped with features like digital controls, programmable settings, and timers, allowing for precise temperature and cooking time management. This has made it easier for chefs to experiment with recipes and achieve consistent results time after time.

Another significant aspect of commercial air fryers is their energy efficiency. With the increasing emphasis on sustainability and cost-effectiveness, these appliances have become more attractive to businesses. They consume less electricity than traditional fryers, which translates to lower energy bills and a smaller carbon footprint.

The market for commercial air fryers is also witnessing rapid innovation. Manufacturers are continuously pushing the boundaries of technology to create more advanced and versatile units. Some of the latest innovations include:

Multi-Functionality: Many modern commercial air fryers can perform a variety of tasks beyond frying, such as baking, roasting, and grilling. This versatility allows operators to use a single appliance for multiple cooking methods, saving space and reducing the need for additional equipment.

Smart Cooking Systems: Integrating smart technology, some air fryers can be controlled remotely via apps or connected to kitchen management systems. This allows for efficient monitoring and operation, even when the chef is not standing over the appliance.

Customizable Cooking Programs: Advanced models offer customizable cooking programs that can be tailored to specific types of food, ensuring optimal cooking times and temperatures for various ingredients.

Enhanced Safety Features: Safety is a top priority in commercial kitchens, and air fryers are being designed with this in mind. Features like automatic shut-offs, cool-touch surfaces, and child-resistant locks are becoming standard.

Energy-Saving Modes: Newer models are designed to save energy during idle periods, with features like sleep mode or automatic power-down after a set period of inactivity.

As the demand for healthier food options continues to grow, the role of commercial air fryers in the foodservice industry is only expected to expand. Operators are increasingly looking for ways to offer their customers a variety of healthy, delicious meals without compromising on taste or texture. Commercial air fryers are well-positioned to meet these needs, as they provide a flexible and efficient solution for preparing a wide range of fried foods in a healthier way.

In conclusion, commercial air fryers have come a long way since their inception. They have become an indispensable tool in the commercial kitchen, offering numerous benefits that align with current dietary trends and environmental concerns. As technology continues to advance, we can expect even more innovative features and improvements that will further solidify the position of air fryers as a staple in modern commercial cooking.

The surge in health awareness has propelled the demand for commercial air fryers, transforming the way we think about cooking and dining. As consumers increasingly seek out healthier alternatives to traditional frying methods, the commercial air fryer market has seen a significant upswing. Fast-casual dining establishments, in particular, are embracing this technology to offer patrons a guilt-free indulgence.

Restaurants and cafes are recognizing the benefits of air frying, which allows for the preparation of crispy, golden-brown foods with a fraction of the oil. This method not only reduces calorie intake but also minimizes the risk of heart disease and other health issues associated with deep-frying. The versatility of commercial air fryers has made them a staple in kitchens worldwide, catering to a diverse range of cuisines from fried chicken to French fries.

The convenience factor cannot be overlooked. Commercial air fryers are designed to save time and effort, allowing chefs to produce large quantities of food quickly. This efficiency is crucial in high-volume operations where speed is key to maintaining service quality. Moreover, the compact size of these fryers makes them ideal for space-constrained kitchens, where every square inch counts.

As the world becomes more environmentally conscious, the energy-saving capabilities of commercial air fryers are also a major draw. These appliances use up to 80% less oil than traditional fryers, leading to lower operational costs and a reduced carbon footprint. This eco-friendly aspect resonates with both businesses and consumers, who are looking for sustainable solutions that align with their values.

The rise of social media and food influencers has also played a significant role in popularizing commercial air fryers. Visual content showcasing the delicious and visually appealing dishes prepared with these fryers has gone viral, sparking curiosity and interest among consumers. As a result, many are now actively seeking out restaurants and cafes that offer air-fried options.

The demand for commercial air fryers has been further fueled by the trend towards “clean eating” and the desire for more natural and unprocessed foods. Air frying allows for the creation of crispy snacks and meals with minimal additives, appealing to health enthusiasts who prefer to avoid artificial ingredients and preservatives.

The foodservice industry is also responding to the growing number of individuals with dietary restrictions, such as those with gluten sensitivities or those following low-carb or keto diets. Commercial air fryers offer a solution that can accommodate these needs without compromising on taste or texture, making them an attractive option for a wide range of customers.

Additionally, the versatility of commercial air fryers extends beyond the kitchen. They are increasingly being used in retail settings, where they can be found in convenience stores and gourmet markets, offering customers the option to purchase freshly fried snacks to go. This dual-purpose use has expanded the market for commercial air fryers, making them a must-have for any establishment looking to offer innovative and health-conscious options.

The demand for commercial air fryers is not just confined to traditional dining establishments. Hospitality venues, such as hotels and resorts, are also integrating these appliances into their operations. They are used to prepare everything from appetizers to desserts, ensuring that guests have access to a variety of delicious and healthy choices.

In conclusion, the growing demand for commercial air fryers is a testament to the changing landscape of the foodservice industry. As consumers continue to prioritize health, convenience, and sustainability, these fryers are becoming an essential tool for businesses looking to meet these evolving needs. With the right marketing and innovation, the market for commercial air fryers is poised to grow even further, offering endless possibilities for chefs and operators alike.

In the realm of commercial kitchen appliances, the air fryer has emerged as a game-changer. These innovative machines have not only revolutionized the way food is cooked but have also sparked a surge in demand. Let’s delve into the factors driving this growth and the evolving landscape of commercial air fryer factories.

The shift towards healthier eating habits has been a major catalyst for the increasing popularity of commercial air fryers. With the rise of fast-casual dining and a growing awareness of the health implications of deep-frying, these appliances offer a solution that allows for crispy, flavorful results with a fraction of the oil. As consumers seek out more nutritious options, the demand for commercial air fryers has surged, creating a lucrative market for manufacturers.

Restaurants and foodservice operators are always on the lookout for ways to streamline their operations and reduce costs. Commercial air fryers have stepped in as a cost-effective alternative to traditional fryers. They consume less energy, which translates to lower utility bills and a smaller carbon footprint. The efficiency of these fryers has made them an attractive option for businesses looking to optimize their kitchen setups.

Another factor contributing to the demand is the versatility of commercial air fryers. They can be used to prepare a wide range of dishes, from fried chicken and French fries to vegetables and seafood. This adaptability means that operators can offer a diverse menu without the need for multiple cooking appliances, saving space and simplifying kitchen layouts.

In response to the growing demand, commercial air fryer factories have been pushing the boundaries of innovation. Here are some of the key advancements that have been making waves in the industry:

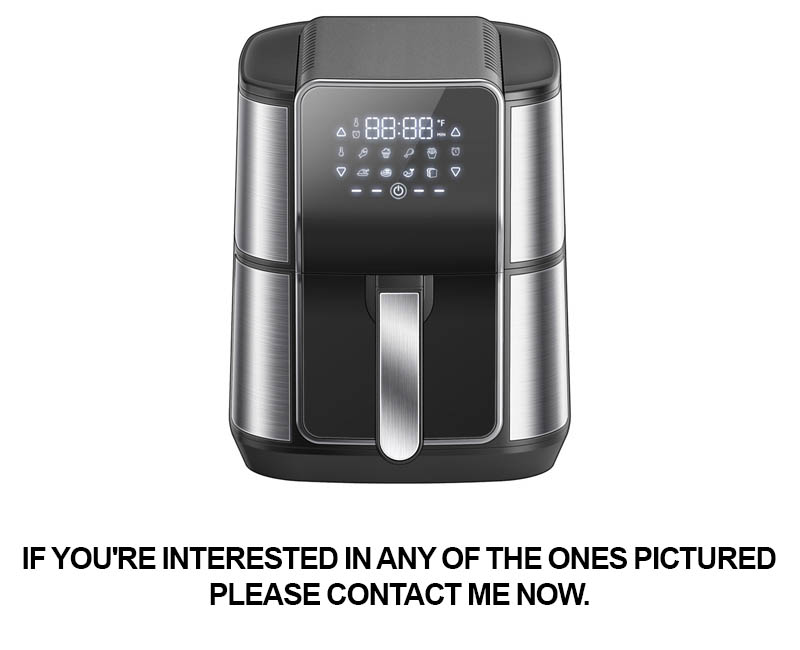

Advanced Heating Systems: Modern commercial air fryers are equipped with sophisticated heating systems that ensure even cooking. These systems can reach high temperatures quickly and maintain them consistently, which is crucial for achieving the perfect texture and flavor in a variety of foods.

Smart Technology Integration: The integration of smart technology has brought a new level of convenience to commercial air fryers. Operators can now control their fryers remotely, adjust cooking times and temperatures, and monitor energy usage through connected apps. This level of automation not only improves efficiency but also enhances safety.

Eco-Friendly Materials: Sustainability is a key concern for many businesses, and commercial air fryer factories have responded by using eco-friendly materials in their products. From the exterior casing to the interior components, these fryers are designed to be more durable and recyclable, reducing the environmental impact over their lifetime.

Energy-Saving Features: Energy efficiency is a top priority in the design of commercial air fryers. With features like automatic shut-off and optimized heat distribution, these appliances consume less energy than their deep-frying counterparts, making them a more sustainable choice for commercial kitchens.

Customizable Cooking Programs: Many commercial air fryers now come with customizable cooking programs that can be tailored to specific types of food. This allows operators to achieve consistent results across their menu, reducing waste and ensuring customer satisfaction.

Safety Enhancements: Safety is paramount in commercial kitchens, and air fryer factories have introduced various safety features to prevent accidents. These include overheat protection, child safety locks, and durable construction that can withstand the rigors of a busy kitchen environment.

Maintenance and Cleaning: Ease of maintenance and cleaning is another area where commercial air fryer factories have focused their innovation. With features like removable parts and non-stick coatings, these fryers are easier to clean and maintain, reducing downtime and labor costs.

As the demand for commercial air fryers continues to grow, so does the competition among manufacturers. The industry is witnessing a constant stream of new products and features that cater to the evolving needs of foodservice operators. The future of commercial air fryer factories lies in continued innovation and a focus on sustainability, efficiency, and safety to meet the expectations of a health-conscious and environmentally aware consumer base.

In today’s fast-paced world, data has become a cornerstone for businesses looking to stay ahead in the competitive landscape. For commercial air fryer factories, harnessing data analytics has become crucial in understanding and shaping industry trends. Here’s how data is at the forefront of innovation and decision-making within this sector.

The Power of Consumer InsightsConsumer behavior is constantly evolving, and data analytics enables manufacturers to track these changes with precision. By analyzing purchase patterns, preferences, and usage statistics, air fryer factories can tailor their products to meet the demands of modern consumers. This might involve a shift towards healthier, low-fat options or more efficient cooking times.

Predictive Analytics for Future DemandPredictive analytics takes consumer insights a step further, forecasting future demand based on historical trends and market indicators. For air fryer factories, this means being able to anticipate which features or designs will be most popular in the coming years. By staying ahead of the curve, manufacturers can ensure they have the right inventory and production capabilities in place.

Enhancing Product DevelopmentData-driven insights don’t just help predict consumer needs; they also inform product development. Air fryer factories are using data analytics to refine their designs, making them more user-friendly, energy-efficient, and durable. This includes everything from optimizing heating elements to improving user interfaces, ensuring that the end product is not just innovative but also practical.

Market Analysis for Strategic DecisionsStrategic decisions are made with a clear understanding of market dynamics. Data analytics provides a comprehensive view of the market, including competitor analysis, pricing strategies, and distribution channels. This information is vital for air fryer factories to make informed choices about where to allocate resources and how to position their products in the market.

Customer Feedback and SatisfactionCustomer feedback is a goldmine of data that can be leveraged to improve products and services. Air fryer factories are using sophisticated data tools to track customer satisfaction, identify areas for improvement, and measure the success of new product launches. This iterative process ensures that products are continuously evolving to meet customer expectations.

Global Market TrendsThe world is becoming more interconnected, and air fryer factories are keeping a close eye on global market trends. Data analytics allows them to monitor how consumer preferences vary across different regions, enabling them to customize their offerings for specific markets. This can range from adapting to local dietary preferences to complying with international safety standards.

Real-Time Monitoring for EfficiencyReal-time data analytics is revolutionizing the production process. Air fryer factories are now able to monitor their operations in real time, ensuring that production lines run smoothly and efficiently. This includes tracking inventory levels, production speed, and quality control, all of which contribute to overall efficiency and cost savings.

Innovation Through Data-Driven PartnershipsCollaboration with academic institutions, research labs, and tech companies has become more common in the air fryer industry. By sharing data and insights, factories can foster innovation that might not have been possible in isolation. This can lead to breakthroughs in technology, materials, and design that push the boundaries of what’s possible in air fryer manufacturing.

In conclusion, the role of data in driving industry trends within the commercial air fryer sector is undeniable. From understanding consumer behavior to optimizing production processes, data analytics is a critical tool that air fryer factories are leveraging to stay competitive and deliver products that resonate with today’s consumers.

The competitive landscape of commercial air fryer factories is a dynamic and evolving field, characterized by fierce rivalry and constant innovation. Here’s an intricate look into the various facets of this competitive environment:

Innovation and Product DifferentiationManufacturers are vying for market share by pushing the boundaries of air fryer technology. They’re introducing features like adjustable temperature controls, multi-functional capabilities, and even customizable cooking programs to stand out in a crowded market.

Global Market ExpansionAs health consciousness spreads across the globe, commercial air fryer factories are not just focusing on local markets. They’re expanding their reach internationally, adapting their products to meet diverse cultural preferences and regulatory standards in different regions.

Strategic Partnerships and CollaborationsTo gain a competitive edge, many factories are forming strategic partnerships with foodservice operators, research institutions, and even tech companies. These collaborations aim to bring cutting-edge technology and insights into the development of new air fryer models.

Quality Control and CertificationQuality is paramount in the commercial air fryer industry. Factories are investing heavily in rigorous quality control processes and obtaining certifications to ensure their products meet the highest safety and performance standards. This not only builds trust with customers but also opens doors to larger contracts with prestigious clients.

Marketing and BrandingMarketing strategies play a crucial role in the competitive landscape. Factories are employing sophisticated branding campaigns, leveraging social media, and attending industry trade shows to showcase their latest innovations and establish their brand as a leader in the field.

Pricing StrategiesPricing is a delicate balance between cost and perceived value. Some factories opt for premium pricing to position their products as top-of-the-line, while others focus on competitive pricing to attract budget-conscious customers. The key is finding the sweet spot that maximizes profit margins without compromising on quality.

Supply Chain ManagementEfficient supply chain management is essential for commercial air fryer factories to stay competitive. Streamlining operations, reducing lead times, and optimizing inventory levels are critical to meeting customer demands and minimizing costs.

Regulatory ComplianceNavigating the complex web of regulations and standards is a challenge for commercial air fryer factories. Compliance with food safety regulations, electrical safety standards, and environmental regulations can be a significant competitive advantage, as it ensures that products can be sold in various markets without legal hurdles.

Customer Feedback and Continuous ImprovementFactories that actively seek customer feedback and use it to improve their products often gain a competitive edge. By listening to what customers want and need, these manufacturers can adapt their offerings to meet evolving market demands.

Technological LeadershipInnovation in technology is a cornerstone of competition. Factories that invest in research and development to create more efficient, energy-saving, and user-friendly air fryers are likely to outpace their competitors in the long term.

Sustainability InitiativesWith increasing environmental concerns, factories are also focusing on sustainability. Implementing green practices, using recyclable materials, and reducing carbon footprints are becoming part of the competitive strategy, as they appeal to eco-conscious customers and stakeholders.

In conclusion, the competitive landscape of commercial air fryer factories is shaped by a multitude of factors, from technological advancements and strategic partnerships to pricing and sustainability. As the industry continues to grow, these factors will likely play an even more significant role in determining the success of individual manufacturers.

In the dynamic world of commercial air fryer factories, navigating regulatory compliance is a complex task that requires a keen understanding of the laws and standards that govern the industry. Here’s a delve into the intricacies involved:

The industry is subject to stringent safety regulations that are designed to protect consumers and workers. These regulations often encompass electrical safety, material handling, and fire prevention, among others. Compliance with these standards is not only mandatory but also a reflection of the company’s commitment to quality and safety.

One of the key challenges is staying up-to-date with the latest amendments to existing regulations and the introduction of new ones. Governments and regulatory bodies frequently update their guidelines, and failing to adapt can lead to legal issues, fines, or even the shutdown of operations.

Ensuring that all products meet the required safety certifications is a critical aspect of compliance. This involves rigorous testing and certification processes from independent bodies that validate the air fryers’ adherence to safety standards. Companies must maintain detailed documentation of these certifications to prove compliance.

Environmental regulations are also a significant consideration. The manufacturing process, the materials used, and the end-of-life disposal of air fryers all fall under the purview of environmental laws. Factories must implement strategies for waste reduction, recycling, and energy efficiency to minimize their environmental impact.

Labor laws dictate the rights and protections of employees, including working hours, overtime pay, and workplace safety. Compliance with these laws is essential for maintaining a positive work environment and avoiding legal disputes.

The quality control process is integral to regulatory compliance. This includes the use of advanced testing equipment to ensure that every air fryer meets the required performance standards. Quality assurance teams monitor every stage of production to identify and rectify any deviations from the established specifications.

Training programs for employees are crucial for compliance. Workers need to be educated on the safety procedures, use of equipment, and the importance of adhering to regulatory guidelines. Regular training sessions help in reinforcing these principles and maintaining a culture of compliance.

Supply chain management plays a pivotal role in regulatory compliance. Ensuring that all components and raw materials used in the manufacturing process are sourced from compliant suppliers is vital. This requires due diligence in supplier selection and ongoing audits to verify their adherence to regulations.

Intellectual property laws also come into play, especially in the context of innovative designs and technologies. Protecting patents and trademarks not only safeguards the company’s investment but also prevents competitors from copying compliant products.

In the face of international trade, navigating customs and import/export regulations is a challenge. Each country has its own set of rules regarding product standards, tariffs, and trade barriers. Staying compliant with these laws requires a comprehensive understanding of international trade practices and the ability to navigate complex bureaucratic procedures.

Finally, legal counsel is often essential for commercial air fryer factories. Attorneys specializing in industrial law can provide guidance on complex legal issues, help draft necessary documentation, and represent the company in any legal disputes that may arise.

The landscape of regulatory compliance in the commercial air fryer industry is multifaceted, requiring a holistic approach that encompasses safety, environmental, labor, quality control, supply chain, intellectual property, international trade, and legal considerations. By addressing these areas with precision and dedication, factories can not only ensure legal compliance but also build a reputation for reliability and trustworthiness in the market.

The commercial air fryer market is on the cusp of significant transformations, driven by both technological advancements and shifting consumer preferences. As we look ahead, several predictions and opportunities emerge that could reshape the industry.

Technological IntegrationThe integration of IoT (Internet of Things) and AI (Artificial Intelligence) is expected to play a pivotal role in the future of commercial air fryers. Smart fryers could offer predictive maintenance, optimizing their performance and reducing downtime. With real-time data analysis, manufacturers can anticipate and meet the evolving needs of customers more effectively.

Health and SustainabilityAs health consciousness continues to rise, there’s a growing trend towards healthier cooking methods. Commercial air fryer factories are likely to focus on developing units that use less oil and provide healthier cooking options. Additionally, the sustainability movement may prompt the use of biodegradable materials and energy-efficient designs, aligning with eco-friendly practices.

Market ExpansionThe demand for commercial air fryers is not confined to the foodservice industry. Opportunities are emerging in other sectors such as retail, where air fryers could be sold as a premium product for home use. The expansion into these markets requires a nuanced understanding of consumer needs and preferences, which can vary significantly from one demographic to another.

Global ReachWith the global trend towards fast-casual dining and the proliferation of international franchises, commercial air fryer factories have the chance to expand their reach. The ability to adapt to local tastes and cooking traditions will be crucial. This could involve customizing fryer models to accommodate specific food types or cultural preferences in different regions.

Innovation in Cooking TechniquesInnovation isn’t just about the fryer itself; it’s also about the cooking techniques. Factories may explore new methods of cooking with air fryers, such as air roasting or air grilling, which could offer additional benefits like better texture and flavor profiles. This could open up new avenues for chefs and foodservice operators to create unique menu items.

Energy EfficiencyEnergy efficiency remains a key concern for businesses worldwide. Commercial air fryer factories are likely to focus on developing more energy-efficient models that can reduce operational costs for their customers. This could involve improvements in insulation, heating elements, and the overall design of the fryer.

Customization and Modular DesignThe future of commercial air fryers may see a shift towards modular and customizable units. Factories could offer a range of components that can be mixed and matched to suit specific kitchen requirements. This could include different sizes, power levels, and even add-ons like digital interfaces or specific cooking programs.

Regulatory ComplianceAs the industry grows, so does the need for regulatory compliance. Factories will need to ensure that their products meet stringent safety and environmental standards. This may involve investing in quality control systems and obtaining certifications that are recognized globally.

Partnerships and CollaborationsTo stay ahead, commercial air fryer factories might look to form strategic partnerships with ingredient suppliers, software developers, and other industry players. Collaborations could lead to the creation of innovative cooking solutions that integrate advanced technology with practical applications.

In conclusion, the future of commercial air fryers is ripe with opportunities. By focusing on technological integration, health and sustainability, market expansion, and innovation, factories can anticipate and adapt to the changing landscape, ensuring a competitive edge in the evolving commercial kitchen environment.

In the ever-evolving landscape of commercial air fryer factories, several notable innovations have emerged, reshaping the industry and setting new standards for efficiency, safety, and innovation. Here’s a glimpse into some of the standout successes:

Energy-Efficient Design: One factory has made waves with its energy-efficient commercial air fryers, which use up to 70% less energy compared to traditional fryers. This not only reduces operational costs for businesses but also minimizes the environmental footprint, a crucial factor in today’s market.

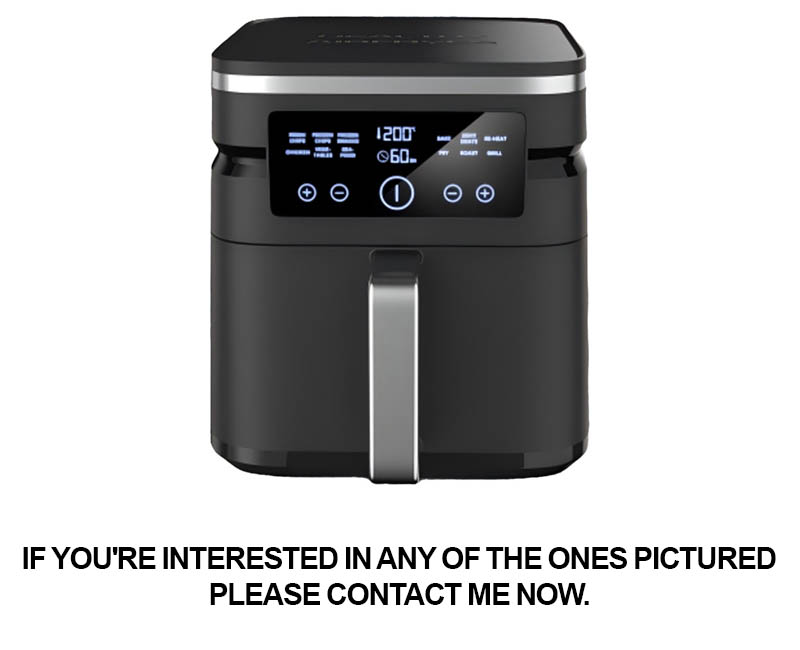

Smart Technology Integration: A leading factory has developed air fryers equipped with smart technology, allowing operators to remotely control and monitor their fryers through mobile apps. This innovation has enhanced productivity and provided peace of mind for businesses, ensuring that the fryers are operating at peak performance at all times.

Enhanced Capacity: To cater to the growing demand for high-volume cooking, a commercial air fryer factory has introduced models with increased capacity. These fryers can process a larger batch of food in a single cycle, significantly reducing the time needed for large-scale foodservice operations.

Customizable Features: Recognizing the diverse needs of different markets, a factory has designed air fryers with customizable features, such as adjustable heat settings and various cooking modes. This allows operators to tailor the cooking process to the specific requirements of their menu items.

Eco-Friendly Materials: An innovative factory has taken sustainability to a new level by using recycled materials and biodegradable components in their air fryers. This not only appeals to environmentally conscious customers but also reduces the cost of disposal and maintenance for businesses.

Healthier Cooking Options: With health being a top priority, a factory has developed air fryers that use a fraction of the oil compared to traditional fryers. This has enabled operators to offer healthier, lower-fat food options without compromising on taste.

Safety Features: A manufacturer has focused on safety, incorporating multiple safety features into their air fryers. These include automatic shut-offs in case of overheating or unauthorized access, as well as clear safety warnings and child locks.

Modular Design: A factory has introduced modular air fryer units that can be easily expanded or reconfigured to meet changing business needs. This flexibility allows for a cost-effective solution that grows with the business, making it a favorite among franchise operations.

Rapid Cooking Technology: To improve efficiency, a manufacturer has developed air fryers with rapid cooking capabilities. These units can cook food up to 50% faster than traditional fryers, which is especially beneficial for fast-casual dining establishments looking to maintain a quick service pace.

Customizable Cooking Systems: A factory has taken customization to the next level by offering air fryers with fully programmable cooking systems. Operators can input specific cooking times, temperatures, and other settings to achieve consistent and precise results with each batch.

These case studies highlight the commitment of commercial air fryer factories to innovation and customer satisfaction. By continuously pushing the boundaries of what is possible in air frying technology, these factories are not only meeting the demands of today’s market but also setting the stage for future advancements in the industry.

The path for commercial air fryer factories is paved with innovation and adaptability. As we look to the future, several key trends and strategies are shaping the industry’s trajectory.

Innovation remains at the heart of progress, with manufacturers pushing the boundaries of what’s possible. This could mean developing fryers that are not only more energy-efficient but also more versatile, capable of handling a wider range of cooking tasks. The ability to switch from air frying to grilling, baking, or roasting with minimal adjustments could revolutionize the commercial kitchen landscape.

Adapting to the changing tastes and dietary needs of consumers is also crucial. As the health and wellness movement continues to gain momentum, air fryer factories must consider the introduction of models that offer healthier cooking options, such as those with adjustable oil capacities or integrated filtration systems to reduce grease content.

Sustainability is another driving force. The industry is increasingly focusing on the lifecycle of their products, from the materials used to the end-of-life recycling programs. Factories that invest in sustainable practices and materials are not only reducing their environmental footprint but also appealing to a growing segment of eco-conscious consumers.

Collaborations and partnerships are becoming more common, with air fryer factories working with culinary experts, food scientists, and even tech companies to create the next generation of fryers. These alliances can lead to groundbreaking features, such as smart technology that allows for remote monitoring and control, ensuring that food is cooked to perfection every time.

Regulatory compliance remains a vital aspect of the industry’s future. As standards evolve, factories must stay ahead of the curve, ensuring that their products meet all local and international safety, health, and environmental regulations. This often requires ongoing research and investment in quality control measures.

Marketing strategies are also evolving. With the rise of social media and online platforms, air fryer factories are finding new ways to engage with their customers. Virtual demonstrations, user-generated content, and interactive experiences are becoming key tools in the marketing arsenal, helping to build brand loyalty and awareness.

The rise of e-commerce has opened up new markets and sales channels for commercial air fryer factories. By embracing online sales, manufacturers can reach customers in remote areas and tap into global markets more easily. This shift also requires a focus on customer service and support, as buyers may have questions or need assistance with their purchases.

Innovation in user experience is another area that holds promise. Factories are exploring ways to make air fryers more intuitive and user-friendly, perhaps through simpler interfaces or even voice-controlled systems. By focusing on the ease of use, they can cater to a broader range of customers, from seasoned chefs to novices looking to experiment with healthier cooking methods.

The future of commercial air fryer factories is also intertwined with the broader foodservice industry. As restaurants and cafes continue to seek ways to offer quick, delicious, and healthy meals, air fryers can play a pivotal role. Factories that understand and anticipate these needs will be well-positioned to provide the solutions that chefs and operators are looking for.

In conclusion, the path forward for commercial air fryer factories is one of continuous improvement and strategic adaptation. By focusing on innovation, sustainability, and customer satisfaction, these factories can not only meet the demands of the present but also shape the future of commercial cooking.