Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

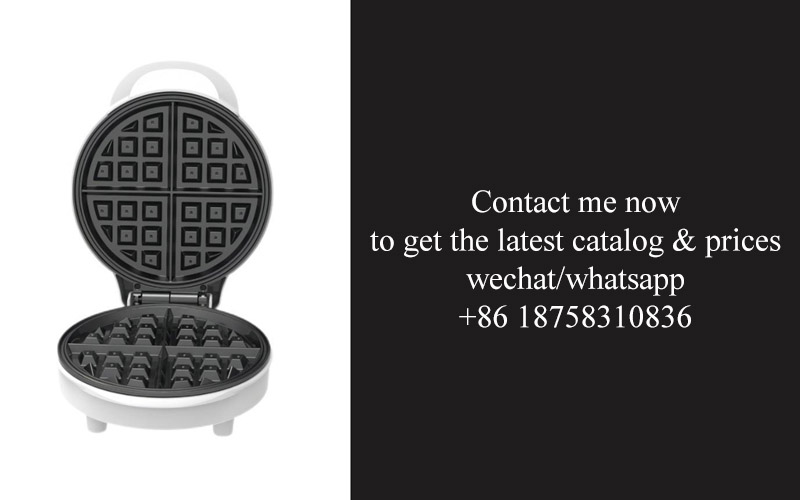

In the ever-evolving world of culinary innovations, one appliance has quietly surged to the forefront, revolutionizing the way we think about waffle making. The industrial waffle maker, with its robust build and powerful performance, has become a staple in commercial kitchens and beyond. As this versatile machine gains popularity, it’s time to delve into the reasons behind its meteoric rise and explore the future it promises.

The kitchen, once a realm of domestic cooking, is now witnessing a revolution with the rise of industrial waffle makers. These sturdy and powerful appliances have transformed the way we think about waffle production, becoming a game-changer in the culinary industry. From small cafes to large commercial kitchens, the demand for industrial waffle makers is on the upswing, and it’s not hard to see why.

Once confined to the breakfast table, waffles have now found their way into a variety of dishes, from sweet treats to savory snacks. The versatility of these delectable breakfast items has been harnessed by chefs and entrepreneurs alike, leading to a surge in the need for high-capacity, durable waffle makers. The rise of industrial waffle makers is not just a trend; it’s a testament to the evolving landscape of foodservice.

The efficiency and speed at which industrial waffle makers operate are unparalleled. These machines can churn out multiple waffles in rapid succession, making them a favorite among busy kitchens that require high-volume production. Their ability to maintain consistent heat and texture throughout the cooking process ensures that every waffle is a perfect replica of the last, pleasing both customers and kitchen staff.

The technology behind these industrial waffle makers has also seen significant advancements. Modern units are equipped with features that enhance their performance and durability. From non-stick surfaces that prevent sticking and make cleanup a breeze to programmable settings that allow for precise control over cooking temperature and time, these machines are designed to withstand the rigors of commercial use.

In the past, the idea of a waffle machine being used in a professional kitchen might have seemed unconventional. However, the popularity of waffles in various cuisines has paved the way for the integration of industrial waffle makers. From the fluffy Belgian-style waffles to the crispy American-style versions, these machines can cater to a wide range of preferences and dietary requirements.

The market for industrial waffle makers has also been influenced by the growing demand for convenience. With more people seeking quick and easy breakfast options, the ability to produce a high-quality waffle in minutes has become a valuable asset. This convenience extends beyond breakfast, as waffles can be used as a base for a variety of dishes, from sandwiches to desserts.

Another factor contributing to the rise of industrial waffle makers is the increasing trend towards health-conscious eating. As consumers look for alternatives to traditional breakfast items like pancakes and toast, waffles offer a lighter, healthier option. With the ability to use whole grains, fruits, and vegetables in waffle recipes, these machines have become a favorite among health-focused eateries.

The rise of the industrial waffle maker is also a reflection of the culinary innovation that’s driving the foodservice industry. Chefs and food entrepreneurs are constantly seeking new ways to differentiate their offerings, and the introduction of unique waffle shapes, sizes, and flavors has opened up a world of possibilities. The ability to customize waffles to meet specific tastes and dietary preferences has become a significant draw for customers.

Furthermore, the economic benefits of using industrial waffle makers are hard to ignore. For restaurants and cafes, these machines can lead to increased revenue through the sale of waffles as a menu item. Their ability to produce a high volume of waffles at a relatively low cost makes them a smart investment for any establishment looking to expand its menu or attract new customers.

In conclusion, the rise of industrial waffle makers is a multifaceted phenomenon that has reshaped the kitchen landscape. From their efficiency and versatility to their ability to cater to health-conscious consumers and drive economic growth, these machines have become an indispensable tool in the professional kitchen. As the demand for waffles continues to grow, it’s clear that the industrial waffle maker is here to stay, and its impact on the culinary world is just beginning.

The world of waffle production has evolved, and with it, the rise of industrial waffle makers has become a game-changer for chefs and businesses alike. One of the most crucial aspects of these machines is their electrical power source, typically the 220V standard. Understanding this voltage and its implications is key to ensuring smooth, efficient, and safe waffle production.

Electrical power is the backbone of any industrial appliance, and the 220V standard is a common voltage used across Europe, Asia, and some parts of Africa. This voltage level is chosen for its balance between energy efficiency and the ability to power high-performance machines. For industrial waffle makers, 220V provides the necessary power to handle the demands of commercial use.

In comparison to other voltage levels, such as 110V, 220V offers several advantages. Firstly, it allows for faster cooking times, as the higher voltage can more effectively heat the waffle grids. This not only increases production rates but also reduces the cost of energy consumption over time. Additionally, the higher voltage can provide more consistent heat distribution, ensuring that every waffle comes out perfectly golden and crispy.

However, it’s important to note that 220V can also pose some challenges. For starters, it requires a proper electrical installation to ensure safety. This means that industrial waffle makers need to be plugged into a dedicated circuit that can handle the power demands without overloading the system. This is especially crucial in commercial kitchens where multiple appliances are in use simultaneously.

Another factor to consider is the compatibility of the 220V standard with different regions. While it is widely used, there are still areas that operate on different voltage levels, such as 110V or 220-240V. Before purchasing an industrial waffle maker, it’s essential to verify that the machine is compatible with the local electrical infrastructure. This may require a voltage converter or transformer to safely adjust the voltage to the appropriate level.

The design of industrial waffle makers that operate on 220V also takes into account the thermal load. These machines are built to withstand the high voltage and the resulting heat output. The heating elements are designed to distribute heat evenly across the waffle grids, ensuring that each waffle cooks uniformly. The thermal insulation and material used in the construction of these machines are also designed to prevent overheating and maintain a safe operating temperature.

When it comes to maintenance, understanding the 220V standard is crucial. Regular maintenance of the electrical components is necessary to prevent any potential hazards, such as electrical shocks or fires. This includes checking the wiring, heating elements, and electrical connections for signs of wear or damage. Additionally, using the correct fuse or circuit breaker is essential to protect the machine and the electrical system from overloads.

Safety features are also a critical aspect of industrial waffle makers designed for 220V operation. These machines often come with features like automatic shut-off mechanisms, thermal cutouts, and grounding systems to prevent accidents. Operators should be trained to recognize and respond to these safety features to ensure a safe working environment.

In the realm of energy efficiency, 220V industrial waffle makers are designed to minimize waste and maximize output. Advanced heating technologies and precise temperature controls help reduce energy consumption while ensuring that waffles are cooked to perfection. This not only benefits the bottom line but also contributes to a more sustainable operation.

In conclusion, the 220V standard is a cornerstone of industrial waffle production. It offers the power needed to meet the demands of a busy kitchen, while also requiring careful consideration of electrical safety, compatibility, and maintenance. By understanding these factors, businesses can ensure that their waffle production runs smoothly, efficiently, and safely.

In the realm of industrial waffle makers, innovation isn’t just about producing the perfect waffle; it’s about streamlining the process, enhancing efficiency, and ensuring durability. When searching for the latest and greatest in industrial waffle maker designs, there are several key features to keep an eye out for:

Efficient Heat Distribution: A top-tier industrial waffle maker boasts even heat distribution across the grid. This feature ensures that every waffle is cooked to perfection, with no cold spots or overcooked edges. Look for machines with precision thermostats and non-stick surfaces that promote consistent heat and easy release.

Large Baking Surfaces: For those looking to cater to a crowd, the size of the baking surface is crucial. Industrial waffle makers with larger grids can produce more waffles at once, making them ideal for commercial settings like cafes, bakeries, and catering services. The ability to accommodate larger batches is a game-changer for businesses aiming to maximize output.

Quick Heat-Up Time: Time is money, especially in a busy kitchen. A high-quality industrial waffle maker should heat up quickly, allowing you to start producing waffles as soon as possible. This is especially important in high-demand situations where every minute counts.

User-Friendly Controls: Modern industrial waffle makers come with a variety of user-friendly controls. Digital displays and intuitive interfaces make it easy to set and monitor the cooking temperature. Some machines even have programmable settings, allowing for customized cooking times and temperatures to suit different types of batter or waffle preferences.

Durable Construction: Since industrial waffle makers are designed for heavy use, they need to be built to last. Look for machines with sturdy, heat-resistant materials such as stainless steel and aluminum. These materials not only ensure longevity but also contribute to the even distribution of heat and the durability of the cooking surface.

Safety Features: Safety should always be a top priority. Industrial waffle makers with safety features like automatic shut-off, cool-touch handles, and overheat protection are essential. These features not only protect the operator but also prevent accidents and potential damage to the machine.

Easy Cleaning: After a long day of waffle-making, the last thing you want to do is spend hours cleaning the machine. Modern industrial waffle makers are designed with easy cleaning in mind. Non-stick surfaces and removable grids make it a breeze to wipe down and keep the machine in top condition.

Versatility: Some industrial waffle makers are designed with versatility in mind, allowing for the creation of various waffle shapes and styles. From classic Belgian to mini or even heart-shaped waffles, a versatile machine can expand your menu options and attract a wider range of customers.

Efficient Power Consumption: While industrial waffle makers require a substantial amount of power, some models are designed to be energy-efficient. This is not only good for your utility bills but also for the environment. Look for machines that balance power consumption with performance.

Brand Reputation and Warranty: Finally, consider the reputation of the brand and the warranty offered. A well-known manufacturer with a strong track record of quality and customer service can give you peace of mind that your investment is in good hands. A comprehensive warranty can also provide reassurance should any issues arise during the machine’s lifespan.

By focusing on these innovative design elements, you can ensure that the industrial waffle maker you choose is not just a tool for the job, but a reliable and efficient addition to your kitchen’s arsenal.

In the bustling world of commercial kitchens, the industrial waffle maker has emerged as a beacon of innovation and efficiency. These machines are not just your average kitchen gadgets; they’re the heartbeat of waffle production, driving the market trends that are currently catching fire. Let’s delve into the reasons behind this surge in popularity.

The demand for quick-service waffles has surged, driven by the fast-paced lifestyle of consumers. With busy schedules and a growing preference for convenience, the industrial waffle maker has become a staple in quick-service restaurants (QSRs) and cafes. The ability to churn out waffles in a matter of minutes is a game-changer for businesses looking to keep up with the demand for freshly made breakfast items.

The rise of health-conscious eating habits has also played a significant role in the market’s shift towards industrial waffle makers. As consumers seek out healthier options, the demand for whole-grain and gluten-free waffles has skyrocketed. Industrial machines can easily accommodate these dietary preferences, offering a variety of settings and options to cater to a diverse customer base.

Customization is another key factor fueling the trend. Modern industrial waffle makers come with a plethora of patterns and designs, allowing chefs and bakers to create unique waffle varieties that stand out on the menu. From classic Belgian to heart-shaped or even novelty designs, the versatility of these machines is a hit with establishments aiming to offer a personalized touch to their offerings.

The technology behind industrial waffle makers has also advanced significantly. With features like digital temperature controls, precise timer settings, and automatic shut-off functions, these machines ensure consistency and safety in every batch. The precision these machines offer is crucial in maintaining quality and reducing waste, which is a top priority for any commercial kitchen.

Eco-consciousness is on the rise, and industrial waffle makers are responding with energy-efficient designs. As businesses look to reduce their carbon footprint, these machines offer a greener alternative without compromising on performance. The energy-saving capabilities not only help in lowering operational costs but also align with the broader sustainability goals of the industry.

The convenience of these machines is undeniable. With the ability to produce multiple waffles at once, industrial waffle makers are perfect for high-volume operations. This efficiency is a major draw for food service operators who need to serve large groups quickly and effectively. The ease of use and minimal maintenance requirements make these machines a practical choice for any kitchen.

Innovation in materials has also contributed to the market’s enthusiasm for industrial waffle makers. Non-stick surfaces and durable construction ensure that these machines can withstand the rigors of commercial use. The longevity of these products means fewer replacements and a lower total cost of ownership over time.

The integration of these machines into the supply chain is seamless. They fit into existing kitchen layouts without the need for extensive renovations. Their compact designs and easy integration with other kitchen equipment make them a versatile addition to any commercial kitchen setup.

The rise of social media and influencer culture has also had a significant impact on the market. With the ability to create visually appealing waffles, chefs and foodservice professionals are using these machines to showcase their culinary skills. The shareability of these creations on platforms like Instagram and TikTok has further propelled the popularity of industrial waffle makers.

The market for industrial waffle makers is also being driven by the desire for international flavors. As global cuisine continues to blend and merge, the ability to produce authentic waffles from around the world is a major draw. From the intricate patterns of Belgium to the hearty flavors of American pancakes, these machines allow for a wide range of cultural offerings.

Lastly, the versatility of these machines extends beyond just breakfast. They can be used for lunch and dinner, creating a variety of sweet and savory waffle dishes that cater to different tastes and occasions. This adaptability is a key factor in the machines’ appeal to a wide range of foodservice operations.

In conclusion, the market trend of industrial waffle makers catching fire is a multifaceted phenomenon. From convenience and customization to technological advancements and environmental considerations, these machines are at the forefront of the commercial kitchen revolution. As the demand for high-quality, quick-service waffles continues to grow, the industrial waffle maker is poised to remain a staple in the commercial kitchen landscape.

In the world of kitchen appliances, the waffle boom has been a fascinating phenomenon. Numbers tell a compelling story, and when it comes to the rise of industrial waffle makers, the data paints a vivid picture of a market on the move.

Sales figures have soared, with a significant increase in the demand for industrial waffle makers over the past few years. The growth rate has been nothing short of impressive, with double-digit percentage points in year-over-year sales. This surge can be attributed to a variety of factors, but one thing is clear: consumers are flocking to these machines for their efficiency and versatility.

Market research indicates that the demand for waffles has expanded beyond the traditional breakfast staple. Foodservice operators are embracing industrial waffle makers to offer a unique menu item that can be a hit at any time of the day. From breakfast buffets to dessert stations, the versatility of these machines is driving their popularity.

The data also reveals a shift in consumer preferences. There’s a growing trend towards healthier eating, and waffles have evolved to cater to this demand. High-protein, gluten-free, and whole-grain options are now commonplace, and this trend is reflected in the sales figures. Consumers are not just looking for a sweet treat; they’re seeking a nutritious one as well.

The rise of the industrial waffle maker is also closely tied to the rise of social media and influencer culture. Visual platforms like Instagram and TikTok have become hotspots for foodies, and waffles have been featured in countless viral posts. The aesthetic appeal of a perfectly golden waffle topped with fresh fruits or a drizzle of maple syrup is hard to resist, and this visual appeal is translating into sales.

In terms of demographics, the market for industrial waffle makers is broadening. While it started with cafes and bakeries, it has now expanded to include schools, hospitals, and corporate catering services. The convenience of these machines, coupled with their ability to produce consistent, high-quality waffles in large quantities, makes them a must-have for any establishment looking to offer a waffle station.

When it comes to the data, there’s also a geographical trend worth noting. The demand for industrial waffle makers is not limited to any one region; it’s a global phenomenon. Countries with a strong coffee culture, such as the United States, Canada, and Australia, are leading the charge, but emerging markets are catching up quickly.

The data also shows that there’s a significant investment in research and development within the industry. Manufacturers are constantly innovating, introducing new features and functionalities to keep up with the market demands. From programmable settings to non-stick surfaces, the technology behind these machines is advancing at a rapid pace.

Another interesting data point is the rise in the use of these machines in home kitchens. As the trend for home baking and cooking continues to grow, more consumers are investing in industrial waffle makers for their own use. The convenience and the ability to produce professional-quality waffles at home are making these machines a staple in many households.

The numbers also tell us that the market for accessories and add-ons is growing. From waffle mixers to toppings, there’s a thriving ecosystem around the industrial waffle maker. This not only extends the life of the machine but also adds value to the consumer experience.

In conclusion, the data behind the waffle boom is a testament to the versatility, convenience, and appeal of industrial waffle makers. From the rise in sales to the expansion of the market and the shift in consumer preferences, the numbers paint a picture of a market that’s not just catching fire but is also setting new standards in the culinary world.

Industrial waffle makers have traditionally been seen as a staple for morning breakfasts, serving up those fluffy, golden Belgian waffles. However, the landscape of these appliances is rapidly evolving, and their versatility is expanding beyond the realm of morning meals. Let’s delve into how these waffle makers are more than just breakfast tools.

From their sturdy build to their advanced features, industrial waffle makers are engineered to handle high-volume production. They’re not just for the breakfast rush at diners and cafes; they’re becoming a versatile asset in a variety of culinary settings. Consider these multifaceted uses:

Dessert Creations: Waffle makers are not just for savory morning treats; they’re also perfect for dessert. By swapping out the traditional batter for sweet ingredients, chefs can craft delectable waffles filled with fruit compotes, whipped cream, or chocolate sauce. This opens up a whole new world of dessert possibilities, from fluffy strawberry waffles to rich chocolate hazelnut creations.

Appetizers and Snacks: The versatility of industrial waffle makers extends to appetizers and snacks. Think of crispy, golden waffle triangles as an innovative way to serve pates, hummus, or even sushi. The waffle shape adds a fun twist to traditional finger foods, making them visually appealing and easy to hold.

Beverage Companions: Not all waffles are meant to be filled with sweet treats; some are designed to pair beautifully with drinks. Imagine a savory waffle with melted cheese, herbs, and a drizzle of olive oil as a perfect companion to a glass of wine or a cup of coffee. The possibilities are endless, from breakfast to an evening apéritif.

Gourmet Meals: Waffle makers can be used to create gourmet meals by incorporating them into dishes that typically don’t involve waffles. For instance, they can be used to make a crispy base for a seafood platter or to cook thin layers of waffle as a crust for lasagna. The key is to think outside the box and experiment with different textures and flavors.

Event Catering: Events often require a variety of food options, and industrial waffle makers can be a hit at catering services. From a casual picnic to a formal gala, the ability to offer a unique and fun food item can set a caterer apart. Waffles can be customized with various toppings and served as a side dish, main course, or a show-stopping centerpiece.

Cultural Integration: The versatility of waffle makers also allows for the integration of different cultural cuisines. For example, you can create Japanese-inspired waffles with teriyaki sauce and vegetables, or Korean-style waffles with kimchi and doenjang. This fusion approach can attract a diverse crowd and cater to specific dietary preferences.

Seasonal Specialties: Waffle makers can be used to create seasonal dishes that are both appealing and practical. Whether it’s a pumpkin spice waffle in the fall or a lemon zest waffle in the spring, these appliances can help bring the changing seasons to your table with a unique twist.

Eco-Friendly and Economical: By using waffle makers, establishments can reduce food waste and be more economical. Leftover bread or buns can be repurposed into waffles, offering a creative solution to leftovers. This not only reduces costs but also promotes sustainability.

Customization for Branding: For businesses looking to create a unique brand experience, waffle makers can be used to imprint logos or messages onto the waffles. This can be a great way to personalize the customer experience and leave a lasting impression.

Educational and Fun: Finally, waffle makers can be a fun tool for educational purposes. Schools, cooking classes, and community centers can use them to teach children about nutrition, cooking techniques, and the art of culinary creativity.

In summary, the industrial waffle maker’s versatility is undeniable. It’s an appliance that can enhance the menu in countless ways, offering both practicality and creativity. Whether you’re looking to add a new twist to breakfast, create a unique dessert, or cater to a diverse clientele, the waffle maker is an indispensable tool in the culinary arsenal.

In the bustling world of commercial kitchens, the efficiency and profitability of every appliance are paramount. Industrial waffle makers, once a niche item, have surged in popularity, offering a myriad of benefits to consumers and businesses alike. Let’s delve into the key advantages that these waffle wizards bring to the table.

Efficiency: The Time-Saver in the KitchenIndustrial waffle makers are designed to churn out waffles at a rapid pace. With their larger surface area and multiple plates, these machines can produce a higher volume of waffles in a shorter amount of time compared to their residential counterparts. This efficiency is a game-changer for busy cafes, restaurants, and food service operations, where time is money. The ability to serve a steady stream of freshly made waffles without the wait can significantly boost customer satisfaction and turnover.

Consistency: The Key to a Quality ProductOne of the biggest challenges in commercial cooking is maintaining consistency. With industrial waffle makers, operators can achieve a uniform texture and size every time. The precise temperature control and even heating ensure that each waffle is cooked to perfection, with a crispy exterior and a soft, fluffy interior. This consistency is crucial for building a reputation for quality, whether you’re a high-end café or a fast-food chain. Customers come to expect the same great taste and appearance, and an industrial waffle maker can deliver.

Profitability: Maximizing Returns on InvestmentInvesting in an industrial waffle maker is a strategic move that can pay off handsomely. These machines are built to last, with durable components and sturdy construction that withstand the rigors of commercial use. They also require less maintenance and have a longer lifespan than many other kitchen appliances. This means fewer unexpected repairs and replacements, which can eat into your bottom line. Additionally, the increased production volume and quality of waffles can lead to higher sales and happier customers, which translates into greater profitability.

Cost-Effective ProductionRunning an industrial waffle maker is a cost-effective endeavor. The energy-efficient design of these machines ensures that you’re not paying through the nose for electricity. Moreover, the high capacity of these waffle makers means you can produce more waffles with fewer machines, reducing the overall energy consumption. This is particularly beneficial for businesses looking to minimize their environmental footprint while keeping operational costs low.

Customization and SpecializationIndustrial waffle makers offer a range of features that allow for customization and specialization. From adjustable temperature settings to various plate designs, these machines can cater to different types of waffles and even other types of baked goods. This versatility not only opens up new menu options but also allows businesses to cater to specific dietary preferences and restrictions, such as gluten-free or vegan waffles. By offering a unique product, businesses can attract a wider customer base and potentially charge a premium.

Enhanced Customer ExperienceThe convenience and quality of waffles made with an industrial waffle maker can significantly enhance the customer experience. Quick service, delicious waffles, and a variety of options can create a memorable visit for customers. This can lead to repeat business and positive word-of-mouth referrals. In a competitive market, standing out with superior products and service is crucial, and an industrial waffle maker can be a key differentiator.

Training and SafetyOperating an industrial waffle maker is straightforward, but proper training is essential for safety and efficiency. These machines can be heavy and hot, so understanding how to use them correctly is vital. Manufacturers often provide comprehensive training programs to ensure that staff are confident in their operation. This not only ensures the safety of your employees but also the quality of the waffles being produced.

In conclusion, the benefits of industrial waffle makers are clear. They offer efficiency, consistency, and profitability that can elevate a business’s offerings and customer satisfaction. By investing in these versatile appliances, businesses can create a unique selling point, reduce costs, and ultimately, increase their bottom line.

In recent years, the industrial waffle maker market has seen a surge in demand, prompting manufacturers to adapt in various innovative ways. Here’s a look at how these companies are evolving to meet the growing needs of consumers and businesses alike.

Manufacturers are focusing on durability and reliability, understanding that industrial use demands robust equipment. They’re using high-quality materials and engineering their machines to withstand heavy use without compromise. The result is a longer lifespan and fewer breakdowns, which is crucial for high-volume operations.

One of the key adjustments has been the incorporation of programmable settings. These allow operators to tailor the cooking process to specific waffle types and consistency levels, ensuring a professional finish every time. Such customization not only satisfies a range of customer preferences but also optimizes efficiency by reducing trial and error.

The trend towards energy efficiency has also influenced the design of industrial waffle makers. As environmental consciousness grows, so does the demand for energy-saving appliances. Manufacturers are responding by developing models that use less power while maintaining peak performance, which is not only eco-friendly but also cost-effective for businesses.

The ability to clean and maintain the machines has become a focal point. Industrial kitchens require regular cleaning to maintain hygiene standards, and manufacturers are creating machines that are easier to clean, with removable parts and non-stick surfaces. This reduces downtime and ensures that the waffle making process can continue without interruption.

Technology integration is another significant adaptation. Many industrial waffle makers now come with digital interfaces that allow for precise temperature control and time management. These features not only make the machines more user-friendly but also reduce the potential for operator error, leading to more consistent and higher-quality waffles.

Customization isn’t just about settings; it’s also about size and shape. Manufacturers are recognizing the diversity of waffle preferences and are offering a variety of mold sizes and designs, from classic Belgian to more exotic shapes like hearts or stars. This caters to specific marketing strategies and niche markets, ensuring there’s a waffle for every consumer.

In response to the demand for a wide range of products, some manufacturers are even producing modular waffle makers that can switch between different mold sizes with ease. This not only saves space in commercial kitchens but also allows for a more dynamic menu without the need for multiple machines.

The demand for flexibility extends beyond the machine’s function. Many manufacturers are also offering flexible financing options, lease-to-own programs, and service contracts to make the initial investment more accessible. This approach eases the financial burden for businesses looking to expand their waffle production capabilities.

As the market continues to evolve, so does the emphasis on health and wellness. With the rise of healthier eating habits, manufacturers are exploring the possibility of non-fat or low-fat options in their waffle maker designs. These healthier alternatives cater to the growing segment of consumers looking for nutritious waffle options.

Moreover, the industry is seeing a push towards sustainability. Manufacturers are exploring the use of recycled materials in their products, reducing their carbon footprint, and contributing to a greener environment. This sustainability focus not only appeals to eco-conscious consumers but also aligns with corporate social responsibility goals.

The rise of foodservice delivery has also impacted the industrial waffle maker market. As more waffles are sold outside of traditional breakfast hours, manufacturers are looking into the development of countertop models that can be easily moved around for catering or mobile foodservice operations.

Lastly, training and support have become integral parts of the package. Recognizing the importance of knowledgeable operators, manufacturers are investing in training programs and offering comprehensive customer support to ensure that their machines are used to their full potential.

In summary, the demand for industrial waffle makers has driven a wave of innovation among manufacturers. By focusing on durability, programmability, energy efficiency, and customization, these companies are not only meeting the needs of the market but also shaping the future of the waffle-making industry.

In the world of culinary innovation, the art of waffle making has evolved far beyond the traditional home kitchen. As the demand for industrial waffle makers surges, manufacturers are at the forefront, continuously adapting and pushing the boundaries of what these machines can do. Here’s a glimpse into the future of waffle making, where emerging technologies and features are reshaping the industry.

The Integration of Smart TechnologyManufacturers are increasingly incorporating smart technology into their industrial waffle makers. Features like touchscreens, digital temperature controls, and programmable settings allow operators to tailor their waffle-making experience with precision. This integration not only enhances user convenience but also opens up new possibilities for customization and consistency in the production process.

Energy Efficiency and SustainabilityAs environmental concerns grow, energy efficiency has become a key focus for manufacturers. Newer models of industrial waffle makers are designed to consume less power while maintaining high performance. The adoption of energy-efficient components and eco-friendly materials reflects a commitment to sustainability, which is increasingly important to both businesses and consumers.

Customization for Diverse MarketsThe global market for waffles is diverse, with different preferences and dietary requirements. To cater to this, manufacturers are offering a variety of waffle molds that can produce different shapes and sizes. From heart-shaped waffles for Valentine’s Day to gluten-free options for a growing segment of health-conscious consumers, the ability to customize waffle makers is expanding the market reach.

Automated Production LinesThe demand for high-volume, consistent waffle production has spurred the development of automated production lines. These lines can handle everything from dough preparation to final product packaging, reducing the need for manual labor and minimizing the potential for human error. The result is a more streamlined and cost-effective production process that can meet the needs of large-scale operations.

Health and Safety FeaturesAs food safety regulations tighten, manufacturers are integrating new health and safety features into their industrial waffle makers. Features like non-stick surfaces that reduce the need for butter or oil, automatic shut-off functions to prevent overheating, and easy-to-clean components are becoming standard. These enhancements not only protect consumers but also simplify maintenance for operators.

Interactive Training ModulesUnderstanding how to use the latest industrial waffle makers effectively is crucial for businesses. Many manufacturers are now offering interactive training modules that can be accessed online or through the machine itself. These modules provide step-by-step guidance and troubleshooting tips, ensuring that operators can get the most out of their equipment.

Enhanced Productivity Through ConnectivityThe connectivity of industrial waffle makers is also improving. With the ability to connect to the internet, these machines can send real-time data on performance, maintenance schedules, and even inventory levels. This connectivity not only helps businesses to optimize their operations but also provides manufacturers with valuable feedback to improve their products.

Innovative Cooking MethodsTraditional waffle makers use heat to cook waffles, but emerging technologies are exploring new methods. Some manufacturers are experimenting with induction heating, which provides faster and more even cooking. Others are looking into the use of infrared technology, which could offer even greater control over the cooking process and potentially reduce energy consumption.

Elevated User ExperienceThe user experience is being elevated with features like built-in Bluetooth connectivity for music streaming, LED lighting for a better work environment, and ergonomic designs that reduce operator fatigue. These additions turn the industrial waffle making process into a more enjoyable and efficient experience for those who use the machines daily.

In summary, the future of waffle making is a blend of cutting-edge technology, sustainability, and customer-centric design. Manufacturers are responding to the demand for versatile, efficient, and user-friendly machines that can meet the needs of a global market. As technology continues to evolve, the possibilities for what industrial waffle makers can achieve are nearly limitless.

In the bustling world of culinary innovation, the industrial waffle maker has emerged as a game-changer, transforming the way we think about breakfast and beyond. It’s not just about the golden, crispy waffles anymore; it’s about a machine that can cater to a variety of culinary needs with precision and efficiency. Let’s delve into why this appliance is not just a kitchen staple but a must-have for any culinary professional or enthusiast.

The rise of the industrial waffle maker has been fueled by a surge in demand for high-quality, consistent waffles, not just for breakfast but for a variety of occasions. The market has seen a shift from traditional, household waffle irons to commercial-grade appliances that can handle the demands of large-scale production. These machines are designed to churn out waffles in rapid succession, ensuring a steady supply for cafes, restaurants, and even food trucks.

Efficiency is key in the kitchen, and industrial waffle makers are a testament to this. They are built to be user-friendly, with features that make operation a breeze. From adjustable temperature controls to non-stick surfaces that simplify cleaning, these machines are engineered to reduce downtime and increase productivity. The ability to produce multiple waffles at once means that time spent waiting for each batch is minimized, allowing chefs to focus on other aspects of their menu.

Consistency is another critical factor in the success of any kitchen. With industrial waffle makers, every waffle comes out with the same texture, shape, and crispiness. This uniformity is crucial for maintaining brand standards and customer expectations. The precision of these machines ensures that the final product is not only visually appealing but also delicious, every single time.

Profitability is a driving force behind the adoption of industrial waffle makers. For businesses, the ability to serve high-quality waffles at a consistent rate can lead to increased sales and satisfied customers. The cost-effectiveness of these machines, when factored into the volume of waffles they can produce, makes them a sound investment. Additionally, the versatility of these appliances allows for the creation of various waffle styles, from classic Belgian to creative flavors, expanding the menu and potentially boosting revenue.

Manufacturers have been quick to adapt to the growing demand for industrial waffle makers. They are not just focusing on the production of these machines but also on enhancing their features and capabilities. One notable trend is the integration of smart technology. Modern industrial waffle makers come with digital displays that allow for precise temperature control and programmable settings. This technology ensures that the machine operates at optimal levels, reducing the risk of overcooking or undercooking.

Another innovation is the development of waffle makers that can produce different shapes and sizes. This flexibility allows for a wider range of products, from the classic square waffle to heart-shaped or even custom designs. Some models even offer the ability to create waffles with unique patterns, adding an extra layer of visual appeal and potential for customization.

In terms of materials, manufacturers are exploring sustainable options. Eco-friendly, durable materials are being used to construct these machines, not only to reduce the environmental impact but also to ensure long-lasting performance. The focus on sustainability is not just a trend but a responsibility that manufacturers are embracing to meet the demands of a more environmentally conscious market.

The future of waffle making is also looking towards energy efficiency. As energy costs continue to rise, manufacturers are working on appliances that consume less power without compromising on performance. This commitment to energy-saving features is not only beneficial for the environment but also for businesses looking to cut down on operational expenses.

In conclusion, the industrial waffle maker has become an indispensable tool in the kitchen. Its efficiency, consistency, and profitability make it a must-have for any establishment that values high-quality, reliable service. As manufacturers continue to innovate and adapt to the market’s needs, the possibilities for waffle making are expanding, promising even more exciting developments in the future. Whether it’s for a busy café, a food service operation, or even a home kitchen looking to elevate its culinary offerings, the industrial waffle maker stands as a symbol of progress and innovation in the world of food preparation.