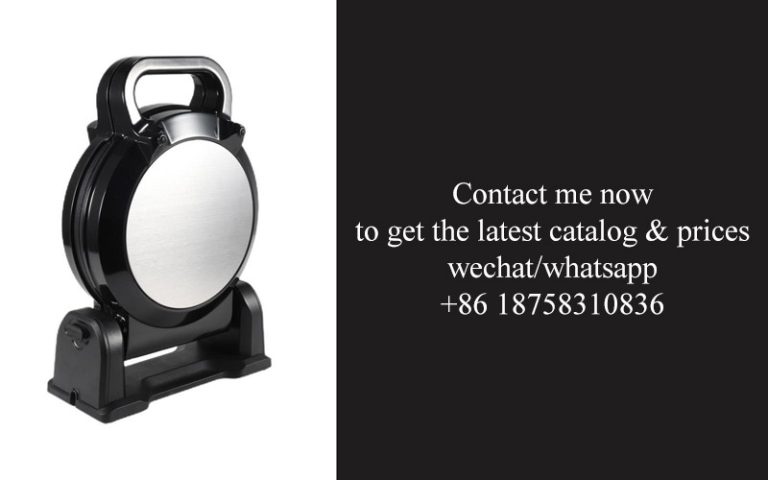

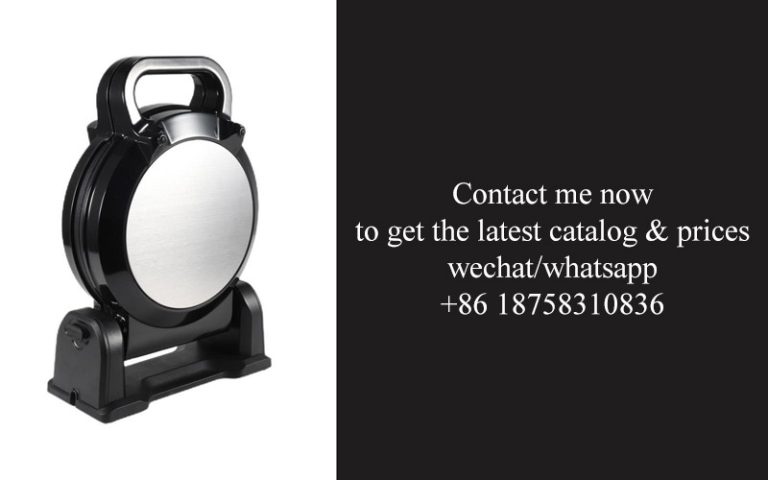

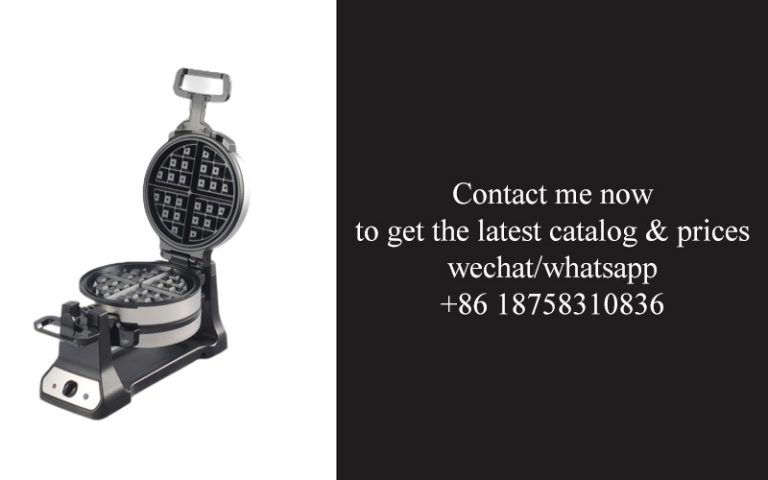

The continuous operation waffle iron plant is at the forefront of enterprise transformation, providing excessive performance and good sized advantages. unlike traditional single-operation models, these flowers can run 24⁄7, extensively boosting production capacity, specially treasured for big-scale catering offerings and bakeries. Their efficiency no longer handiest meets the needs of the modern cityscape however additionally gives a contrast advantage over single-operation gadgets. through decreasing downtime and improving typical manufacturing performance, those vegetation provide enormous value savings and operational advantages, making them a compelling desire for groups aiming to thrive inside the aggressive marketplace.

As consumer demands for kitchen appliances grow greater numerous and personalised, especially in baking, the OEM marketplace for forged aluminum wafer molds is witnessing big increase. producers are responding to this fashion by supplying customized, health-conscious, and multi-useful mold designs. This surge in call for is not limited to metropolis markets however is global, pushed by using the popularity of healthful eating and the rise of clever kitchen technology. With a focus on progressive product design and sustainable materials, OEM manufacturers are poised to keep driving the industry’s expansion, both in baking and across diverse kitchen equipment sectors.

inside the technology-driven cityscape, hydraulic press production is witnessing a surge in technological improvements, propelling performance gains for producers. With a focal point on revolutionary technologies, these companies are streamlining operations, embracing automation, and optimizing designs to reduce electricity consumption and enhance productivity. the mixing of clever structures and lightweight materials isn’t always simplest lightening the presses but additionally improving their accuracy and reliability. As a end result, producers in this zone are positioned to fulfill the evolving needs of various industries, from automotive to aerospace, with specialised and customized answers that cater to the precise desires of every city’s manufacturing landscape.

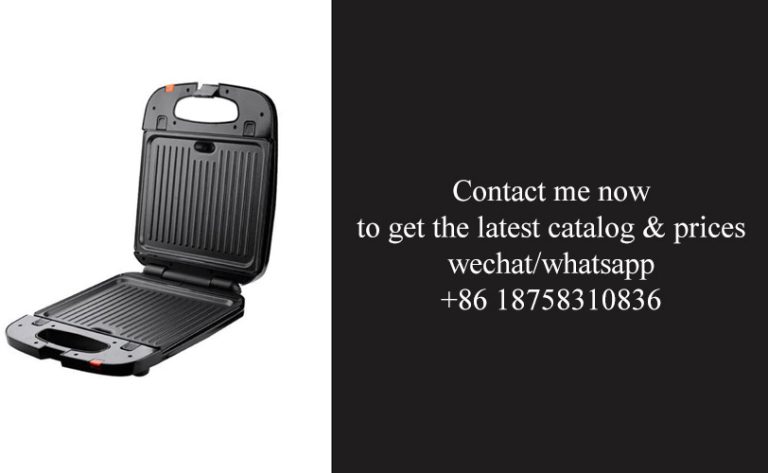

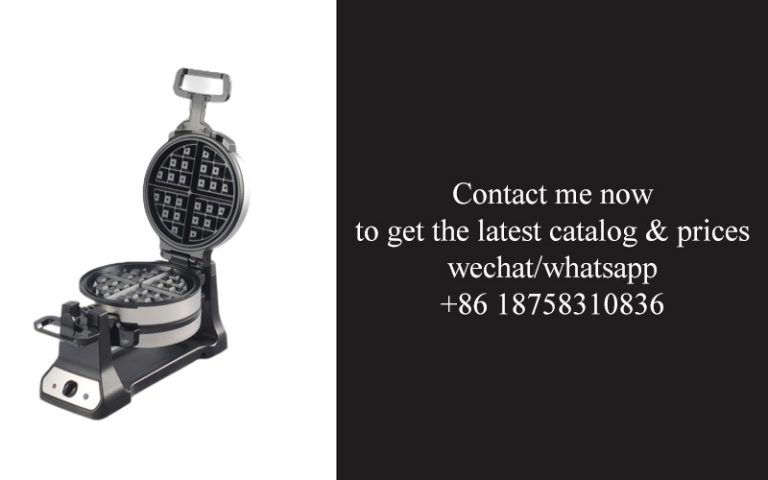

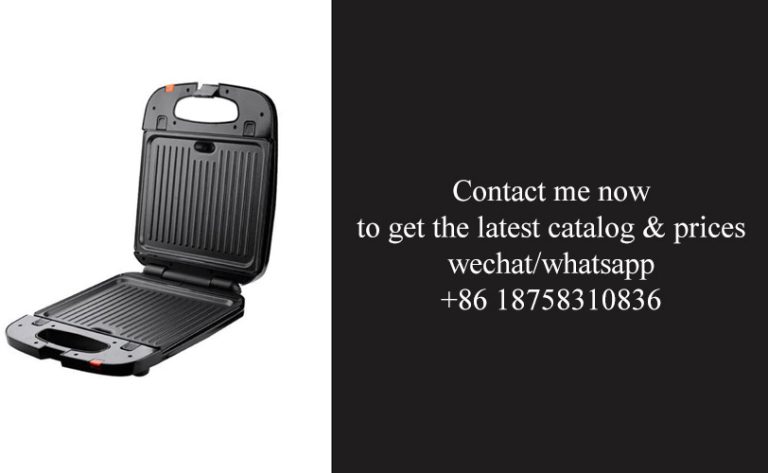

The NSF-certified industrial waffle maker has emerged as a market leader in the appliance enterprise, presenting a mix of advanced first-rate, revolutionary features, and robust performance. those waffle irons meet stringent NSF standards, ensuring protection, sturdiness, and compliance with global regulations. Key functions include clever manage systems, strength-efficient designs, and flexible multi-practical abilities, making them perfect for numerous commercial settings. With their non-stick surfaces, easy upkeep, and glossy aesthetics, these industrial waffle irons aren’t handiest a fave among cooks but additionally a trendsetter inside the business kitchen appliance quarter.

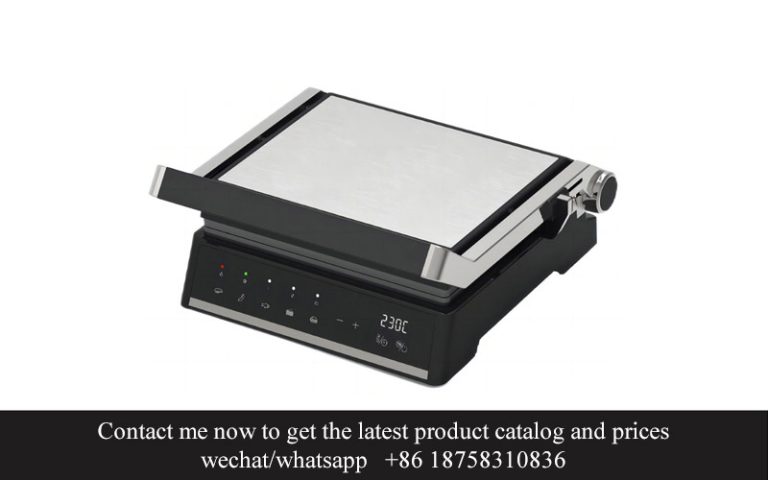

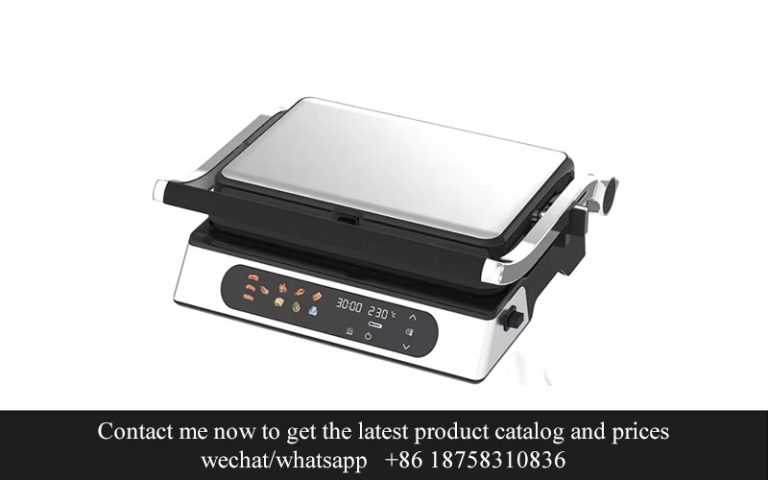

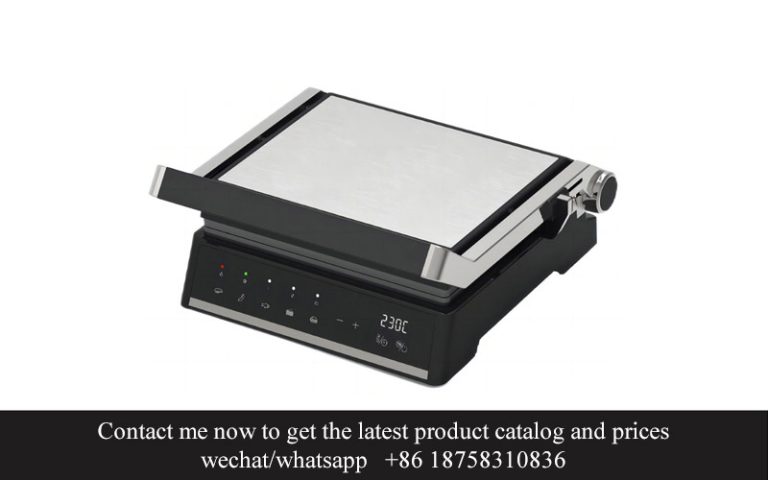

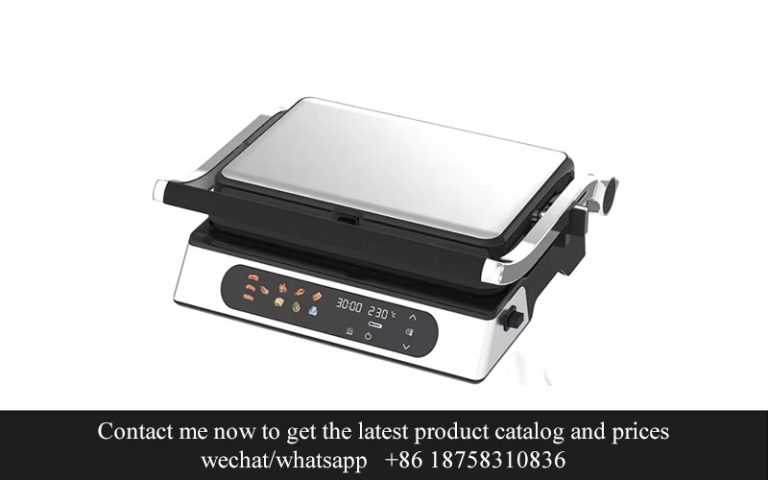

The kitchen equipment industry is increasingly more embracing ISO 22000 food safety standards to make certain product safety and efficiency. implementing the ISO 22000 widespread inside food protection factories ensures rigorous procurement procedures and stringent hygiene measures, improving the general satisfactory of appliances. This certification now not handiest ensures safety from raw cloth procurement to very last product transport but additionally boosts operational efficiency, main to marketplace trends that prioritize customer believe and pleasure.

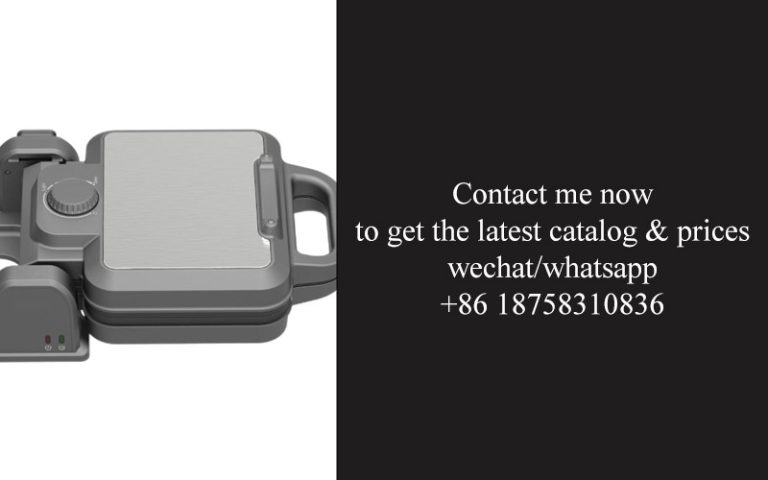

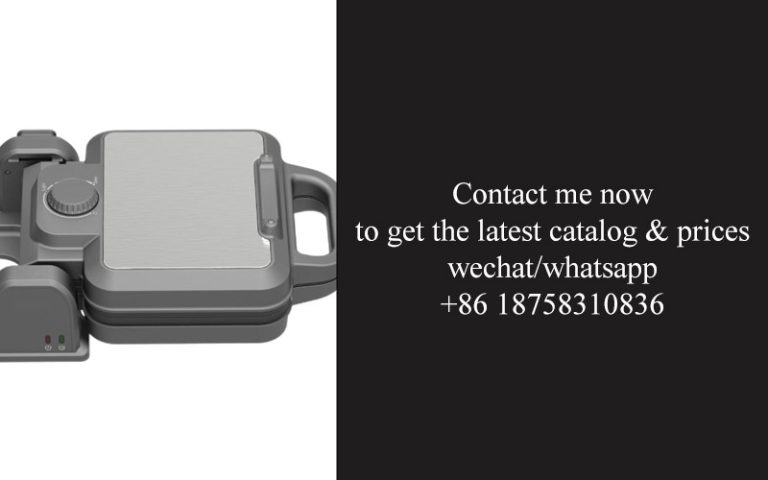

The double-sided flip waffle maker for food vehicles is a innovative appliance that appreciably complements operational performance and convenience. Its modern design permits for simultaneous waffle cooking on both sides, lowering coaching instances and maximizing space in cell catering vehicles. With its compact and transportable nature, it is a great choice for food vans seeking to provide a various menu with out compromising on overall performance. this flexible and efficient equipment is poised to end up a famous preference inside the mobile catering industry, imparting both velocity and first-rate to fulfill customer needs.

Ceramic covered waffle plates are revolutionizing the kitchen appliance marketplace with their BPA-free, non-stick surfaces and fitness-aware design. those innovative appliances not best decorate cooking reports with their even warmth distribution and crisp waffles but also cater to the growing call for for

and secure kitchenware. As consumers prioritize health and sustainable living, ceramic lined waffle plates are poised to emerge as a staple in modern kitchens, offering both practicality and peace of thoughts.

The kitchen appliance industry is presently experiencing a surge in innovation, pushed by the increasing variety and personalization of purchaser demands. to satisfy those evolving needs, certain era offers a 20-day speedy prototyping ODM pattern service, catering to the growing demand for personalization within the european and American markets. Our service consists of green layout affirmation, sample production with advanced generation, and iterative layout approaches to ensure fine and meet expectations. by using emphasizing innovation and performance, we provide modular designs and integrate

functions, including smart fitness management and strength-saving technology, to deliver marketable merchandise quick. Our commitment to high-quality and patron delight has earned us massive reward in the industry.

The NSF/ANSI 4 licensed waffle maker has emerged as a market preferred amongst city purchasers. diagnosed for its safety and performance, those appliances are gaining traction because of their stringent certification requirements. main producers within the city are embracing this certification, making sure their waffle makers meet high protection and health necessities. The sure brand, mainly, is making waves with its NSF/ANSI four certified waffle makers, which aren’t most effective dependable however additionally elegant and smooth to use, solidifying their function as a top preference in the appliance market.

The UL 197 commercial popular has emerged as a essential benchmark for kitchen equipment safety, extensively impacting each manufacturers and clients in foremost cities. This wellknown, established with the aid of Underwriters Laboratories, sets stringent necessities for layout, materials, installation, and overall performance, aiming to make sure the reliability and safety of business kitchen equipment. by means of adhering to UL 197, manufacturers in towns like the big apple, London, and Tokyo are improving product nice, selling purchaser believe, and fostering technological innovation, in the end shaping a safer and extra efficient equipment marketplace.