The EAC Waffle Maker factory has turn out to be a standout inside the kitchen appliance market with its modern and various product line. Its waffle irons, providing smooth designs and clever cooking programs, cater to ecu and American purchasers’ options for cultured appeal and functionality. The manufacturing unit’s awareness on safety, portability, and environmental cognizance, at the side of its commitment to after-sales carrier, has garnered excessive patron pride. With market information displaying consistent growth and an outstanding CAGR of over eight%, the EAC Waffle Maker manufacturing facility is poised to make bigger its product line, optimize power consumption, and make stronger its international logo presence, making sure a brilliant destiny inside the competitive equipment enterprise.

The Arctic Grade Waffle Maker has emerged as a standout in the kitchen equipment marketplace, shooting attention for its progressive layout and remarkable performance. Made with cold-resistant materials, this equipment ensures durability in extreme situations, making it best for each home use and outdoor adventures. Its fast heating, precise temperature control, and non-stick coating cater to the demand for convenient and healthy cooking. The Arctic Grade Waffle Maker’s reputation has surged in Europe and the united states, driven by means of its versatility, marketplace call for for

home equipment, and its potential to beautify each day cooking experiences. as the kitchen appliance marketplace maintains to evolve, the Arctic Grade Waffle Maker is poised to lead the way with its

features and commitment to consumer pride.

OEM kitchen appliance manufacturers are driving industry transformation thru progressive product design and strategic marketplace insights. They stay abreast of global trends, deeply apprehend client wishes, and collaborate with upstream and downstream industries to ensure satisfactory and efficiency. via investing in R&D, they expand smart, power-green home equipment with person-friendly functions, catering to modern life. Leveraging data evaluation, those producers awareness on intelligentization, sustainability, customization, and pass-enterprise integration to enhance competitiveness and make bigger their marketplace proportion within the dynamic kitchen appliance quarter.

the commercial waffle maker marketplace is witnessing strong increase, driven by way of the growing demand for fitness-conscious breakfast alternatives. producers are responding with progressive, strength-efficient designs, such as clever waffle irons with programmable controls and automated cleansing functions. as the market expands, opposition is fierce, with brands focusing on product differentiation and customization. commercial waffle maker factories, just like the one we’re discussing, are certain to keep performance through smart layout, material choice, and deliver chain management, making sure they continue to be aggressive and meet the evolving desires of customers and the industry.

The Ningbo small appliance supplier has surged ahead, achieving monthly sales of 10,000 gadgets, showcasing the sturdy increase of Ningbo’s kitchen equipment industry. thanks to particular market insights, relentless innovation, and a focal point on

products like smart ovens and air fryers, this supplier has established itself as a leader inside the quarter, leveraging a mix of smart layout, marketplace acumen, and strategic supply chain management. The surge in income not only highlights the energy of Ningbo’s small appliance marketplace however additionally underscores its position as a worldwide leader in kitchen home equipment.

The kitchen system industry is experiencing a high-quality transformation, with the East Coast OEM production gadgets leading the fee. these factories, strategically located in China’s coastal area, provide green,

products and services, assembly international demands. Their innovative technology and competitive pricing, along with a minimal order quantity of simply 500 gadgets, cater to each small groups and huge organizations. The industry trend now prioritizes innovation and efficiency, with clever appliances, electricity-saving functions, and fitness-aware designs becoming the norm. This shift not best complements cooking reports however also guarantees sustainable increase within the kitchen gadget sector.

The CE-certified air fryer OEM market has surged because of rising fitness cognizance, with producers focusing on low-fats cooking. those OEMs are essential to the marketplace, supplying customized, multifunctional air fryers that meet strict ecu protection requirements. progressive layout is pivotal for these manufacturers, making sure product protection, improving user experience, and boosting market competitiveness. through adhering to CE certification necessities, those OEMs can hopefully input the eu marketplace, relaxed a bigger share, and establish a reputable emblem photograph.

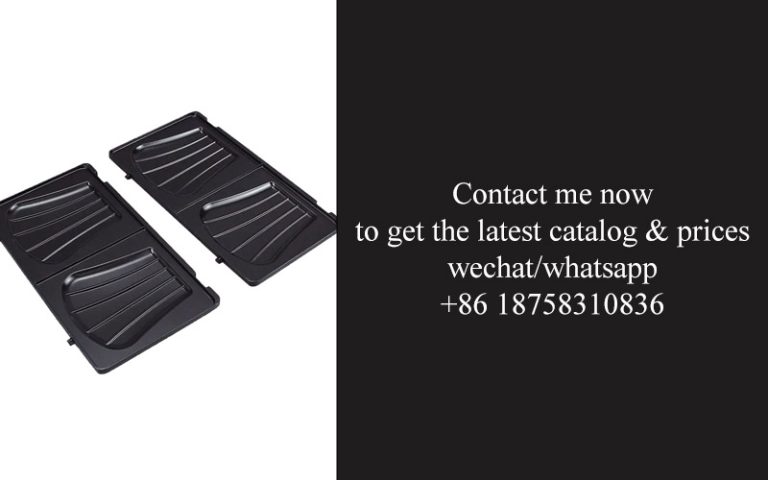

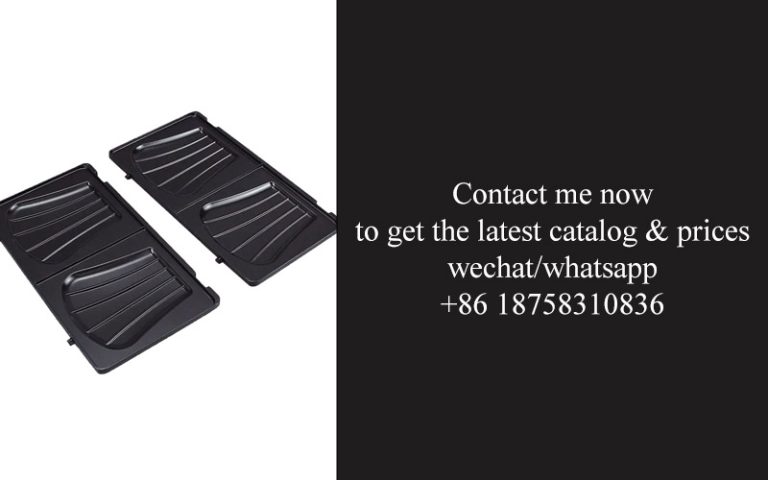

Amidst globalization’s surge, the kitchen appliance industry, significantly sandwich makers, is undergoing rapid transformation. EAC compliant sandwich maker factories, adhering to stringent protection and environmental standards, are pivotal on this shift. these facilities, like the Meiji factory, introduce modern products that cater to fitness-conscious customers and the fast-paced town life-style. with the aid of imparting multifunctional, well designed sandwich makers, they make sure particular cooking for advanced flavor. furthermore, these EAC certified home equipment are a positive manner to cook dinner scrumptious sandwiches while meeting global fine and safety requirements, making them a popular preference in urban families and commercial settings alike.

Low MOQ air fryer manufacturers are capitalizing on the developing call for for healthful cooking home equipment via introducing innovative models. those producers, with their reduced minimum order portions, are reducing access limitations and fostering market diversification. they’re leveraging online income channels and focusing on smart, strength-green designs, including contact-screen controls, multi-practical units, and

materials. To compete, they’re improving person enjoy, exploring pass-enterprise collaborations, and making an investment in R&D to create unique products that cater to various patron wishes, even as additionally targeting global markets for enlargement.

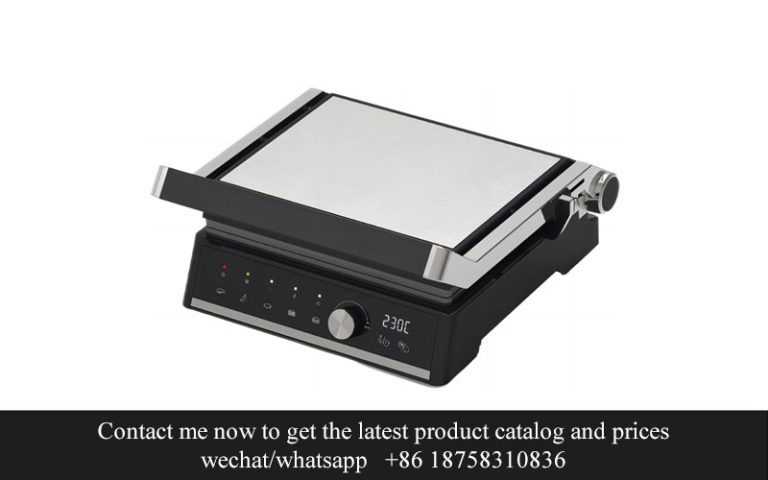

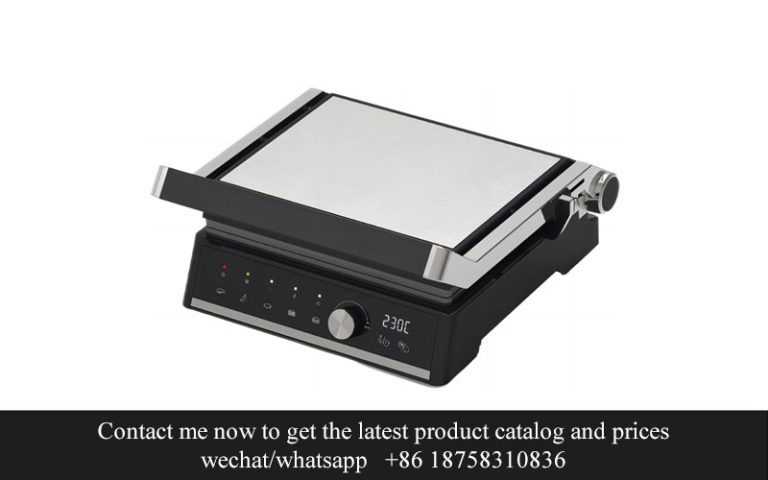

The customizable touch grill OEM market is witnessing large traits, with a developing demand for personalized capabilities and designs. To preserve tempo, producers are innovating with smart temperature control, computerized cleansing, and

materials, while also specializing in cost reduction. An modern solution has finished a 30% value discount through advanced substances, clever manufacturing, optimized supply chains, included layout, and energy-saving technologies. This price performance, combined with the upward thrust of on-line income channels and the call for for high-quit products, is anticipated to drive marketplace boom. As competition intensifies, producers should maintain to innovate and cater to various customer needs to preserve their market function.