The 2200W european Plug Air Fryer, a famous OEM appliance, is riding innovation inside the kitchen market due to its healthful cooking abilties. This air fryer, known for its efficient low-fats cooking, is a favorite amongst clients seeking more healthy existence. Its fast heating performance and particular design have located it at the vanguard of the enterprise, with a growing market ability. With an emphasis on product differentiation, stringent uncooked cloth choice, and market segmentation, the 2200W eu Plug Air Fryer OEM is poised for extensive increase, attracting each domestic and worldwide brands to compete in this burgeoning section.

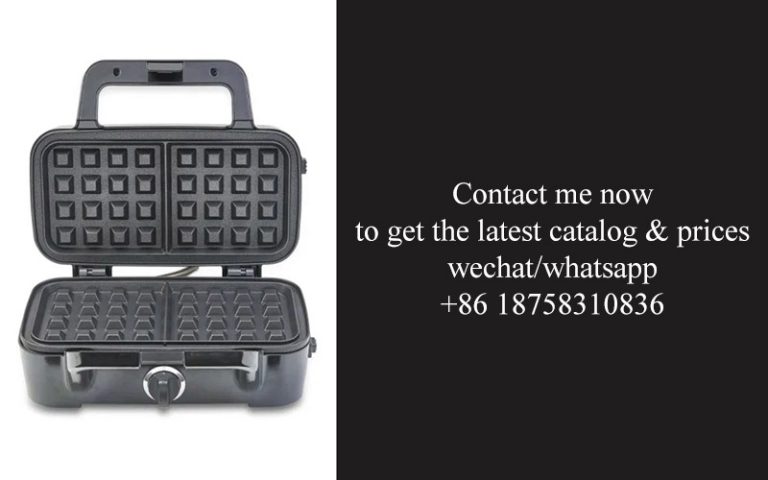

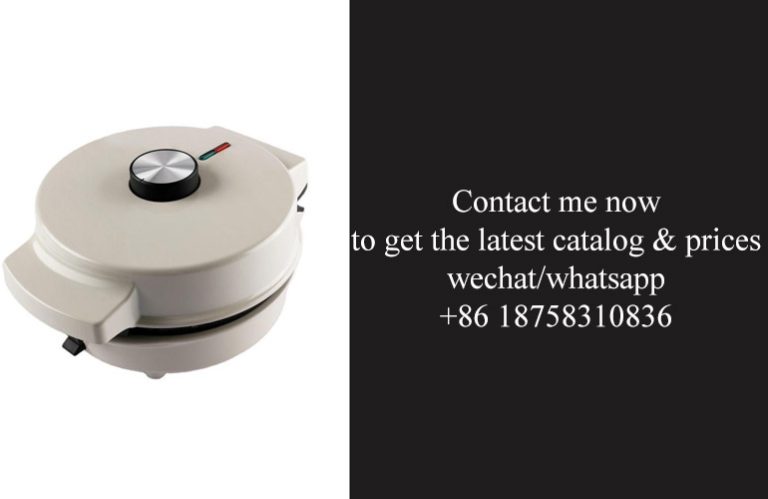

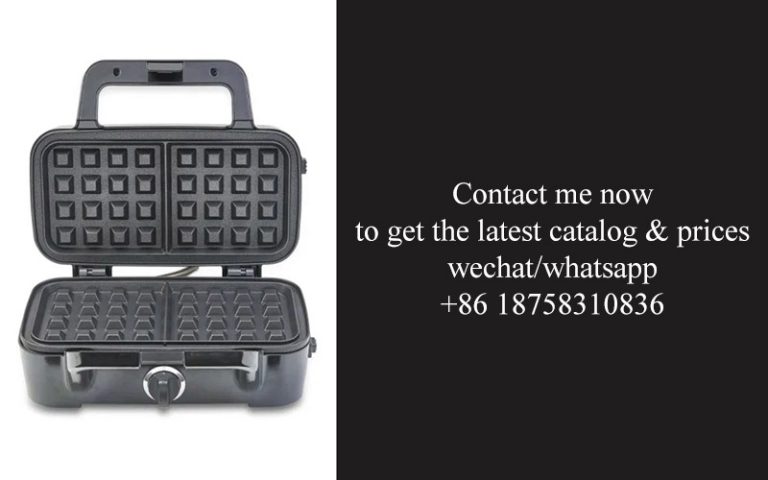

the economic grade waffle maker market is witnessing a surge due to its specific texture and simplicity of operation. amongst numerous kitchen appliances, these waffle irons are gaining traction, particularly with the advent of NSF-licensed models. these home equipment provide a safety guarantee via adhering to stringent sanitation and overall performance standards, enhancing their marketplace competitiveness. agencies are leveraging the benefits of these NSF-licensed waffle makers for his or her sturdiness, shrewd manipulate systems, and multifunctional designs, making them a desired preference for catering, inns, and greater. With an growing call for for healthful eating and heightened awareness of food safety, these industrial waffle makers are poised for vast marketplace growth.

The rise of BPA-free substances in juicers has been a tremendous fashion inside the equipment industry, pushed by means of purchaser demand for healthier and environmentally pleasant alternatives. cloth factories specializing in those substances are at the vanguard, improving product protection and durability. manufacturers are leveraging these innovations to differentiate their products, supplying no longer only fitness benefits but also improved aesthetic and practical capabilities. the usage of advanced substances is raising manufacturing charges, but those are offset through extended market fee and the attraction of top rate, eco-aware products. This shift is bolstering global competitiveness for equipment manufacturers, especially within the juicer area.

The Russian kitchen equipment marketplace, witnessing constant increase, is a crucial segment for providers. As a key component of domestic life, kitchen home equipment, along with cooking gadgets, are in high demand. suppliers have to make certain strong logistics to preserve efficiency. This includes managing huge, precision device with excessive safety requirements, navigating Russia’s considerable and sparsely populated areas, and adapting to various climates. efficient logistics not handiest guarantees timely delivery and product integrity however additionally enhances consumer satisfaction and emblem credibility, important for competing in a marketplace with each domestic and international players.

The air fryer OEM market is experiencing rapid increase, pushed by patron call for for healthful cooking alternatives. manufacturers are that specialize in product innovation and smart capabilities, even as emphasizing the importance of warranty substitute to enhance logo reputation and consumer believe. by means of providing clean, green warranty guidelines and short reaction to after-sales problems, OEMs like certain are differentiating themselves, fostering loyalty, and solidifying their aggressive side within the appliance enterprise.

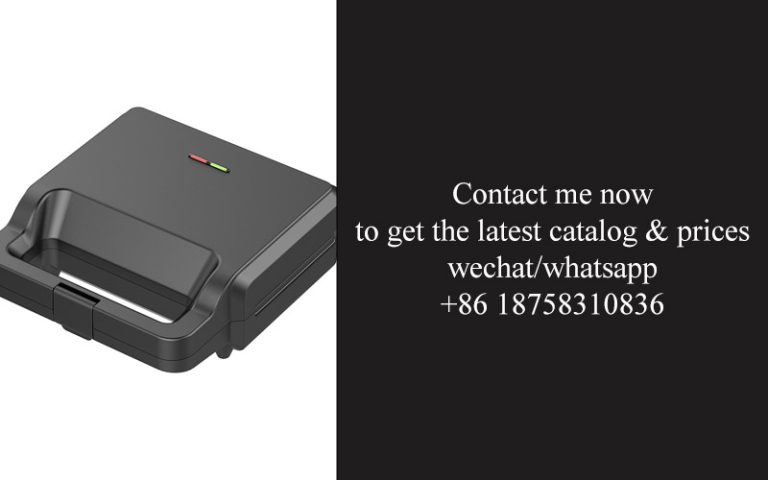

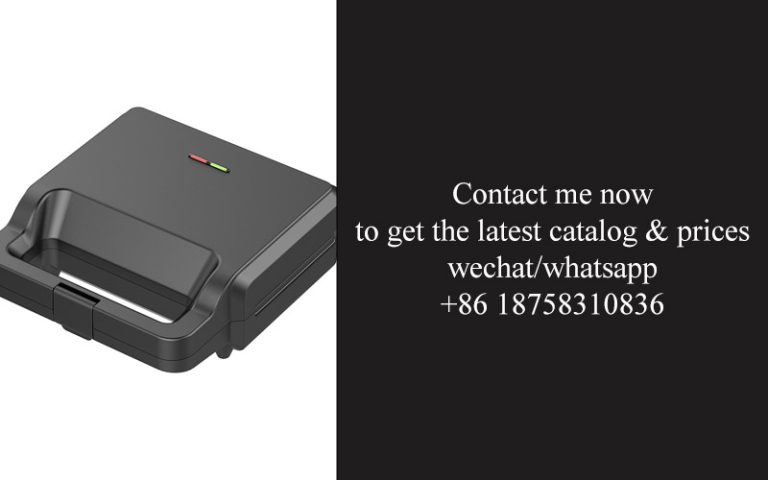

In Ningbo, China, FOB (loose On Board) sandwich maker providers are at the forefront of the kitchen appliance industry, experiencing speedy growth. Leveraging their strategic place as a key port city, Ningbo suppliers offer a comprehensive industrial chain, from raw substances to finished products. They concentrate on a huge range of sandwich makers, from domestic to commercial use, with a focus on innovation like smart temperature manipulate. Their products are notably in demand for his or her quality and efficiency, in particular in the ecu and American markets. With era driving the industry, Ningbo’s providers are continuously improving their offerings, inclusive of power-saving and portable designs, to cater to the evolving cooking tendencies and customer needs.

The 1200W commercial air fryer has revolutionized cooking with its innovative technology. This high-powered appliance offers a healthier alternative to traditional frying, using up to 80% less oil while delivering crispy, golden results. Its large capacity and versatile cooking modes, including frying, roasting, and baking, make it a game-changer in commercial kitchens. The 1200W rating ensures rapid cooking times, efficiency, and consistent performance, making it an indispensable tool for any establishment aiming to enhance menu offerings and cater to health-conscious consumers.

The 4-slice sandwich maker has become a staple in kitchens worldwide, thanks to its convenience and efficiency. As an OEM product, these appliances offer a range of features, including non-stick surfaces, adjustable heat settings, and programmable timers for perfect cooking. With their ability to handle multiple slices at once, these sandwich makers cater to both home chefs and commercial kitchens, providing versatility and ease in meal preparation. The latest models also integrate smart technology, allowing for remote control and customization, further enhancing the cooking experience.

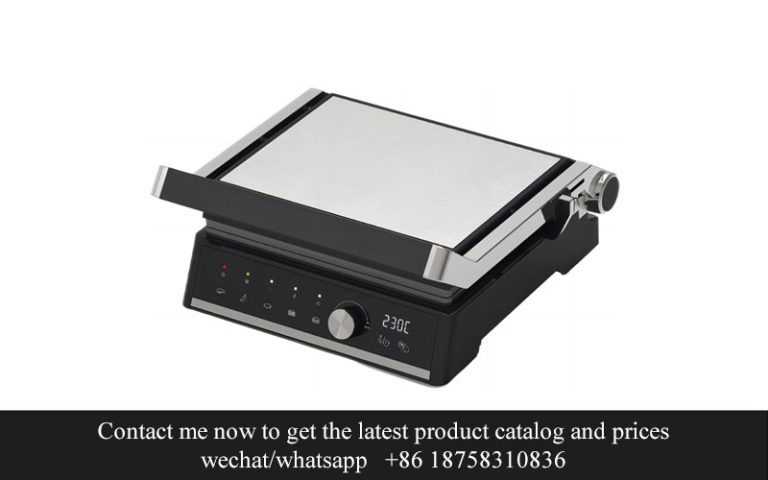

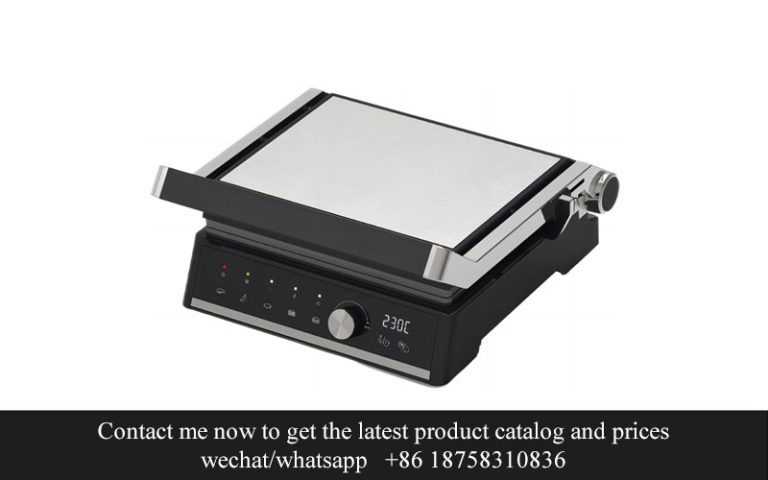

The stainless steel contact grill has revolutionized outdoor cooking with its sleek design, innovative features, and practical benefits. Constructed from durable stainless steel, these grills offer even heat distribution, a non-stick surface for easy cleanup, and safety features like cool-touch handles. Their versatility allows for a wide range of dishes, from meats and vegetables to sandwiches, all while locking in flavors and reducing oil usage. As a testament to modern kitchen innovation, the stainless steel contact grill seamlessly blends aesthetics and functionality, becoming a must-have for any culinary enthusiast.

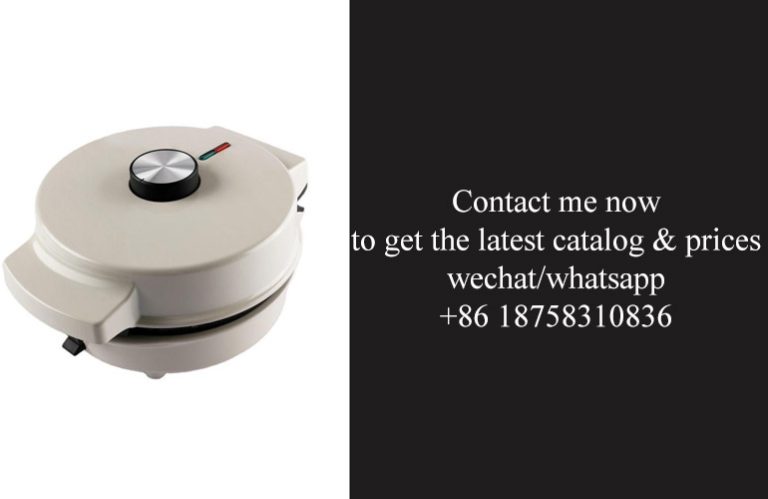

The industrial waffle maker, operating on a 220V standard, has surged in popularity due to its efficiency and versatility, making it a must-have for businesses. Manufacturers are responding by integrating advanced features, such as programmable settings and energy-efficient designs, to enhance performance. These robust machines are not just for breakfast; they offer a range of shapes and sizes, catering to diverse customer preferences. Their durable construction and user-friendly controls make them a cost-effective investment, driving profitability for any establishment looking to offer high-quality waffles.