Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

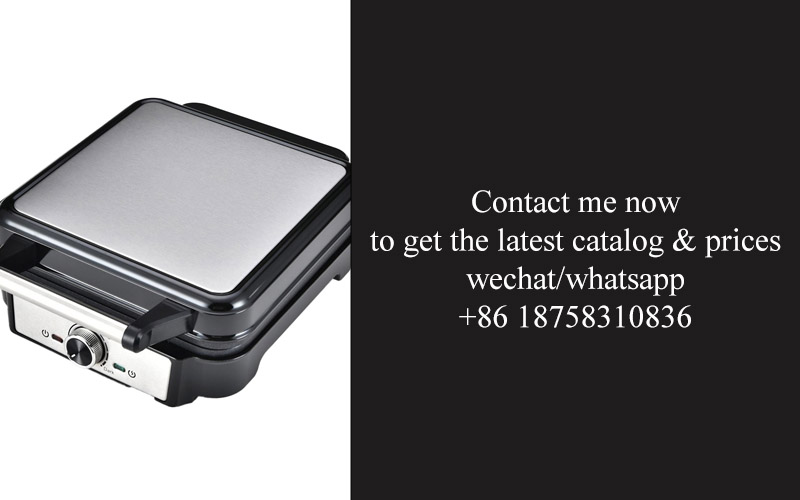

In the bustling world of foodservice and home cooking, the heavy-duty sandwich press has become an indispensable tool. These robust appliances have not only transformed the way we enjoy our sandwiches but have also carved a niche in the commercial and industrial sectors. Today, we delve into the fascinating journey of the heavy-duty sandwich press, exploring its evolution, the role of factories in its production, cutting-edge innovations, market trends, the impact of technology, success stories, industry challenges, and the paramount importance of quality control in manufacturing. As we conclude, we’ll glimpse into the future of heavy-duty sandwich press factories, envisioning a landscape of innovation and growth.

The heavy duty sandwich press market has emerged as a crucial segment within the culinary equipment industry, catering to a variety of commercial kitchens and foodservice establishments. These robust appliances are designed to withstand the rigors of high-volume production, ensuring consistent and professional-quality sandwiches for patrons. In this bustling market, where innovation meets durability, let’s delve into the intricacies that define the heavy duty sandwich press landscape.

Heavy duty sandwich presses are not your average kitchen gadgets; they are engineering marvels that can withstand the test of time and intense use. From bustling fast-food chains to gourmet sandwich shops, these presses play a pivotal role in the preparation of everything from classic ham and cheese to gourmet grilled creations. The market for these powerful tools is witnessing a surge in demand, driven by the growing popularity of casual dining and the rise of food trucks that require reliable, efficient equipment.

As the market expands, so does the competition among manufacturers. Heavy duty sandwich press factories are at the forefront of this race, constantly pushing the boundaries of design and functionality to meet the evolving needs of the industry. These factories, often located in industrial zones, are hubs of innovation where state-of-the-art machines are crafted to perfection.

The manufacturing process for heavy duty sandwich presses is a blend of traditional craftsmanship and modern technology. Steel frames, durable materials, and precise engineering ensure that these presses are not only built to last but also to deliver the desired outcome with every press. The attention to detail in these factories is remarkable, with every component meticulously tested for quality and durability.

One of the standout features of heavy duty sandwich presses is their ability to cook and toast sandwiches simultaneously, saving valuable time in the kitchen. The even heat distribution and the ability to customize cooking temperatures make these presses versatile tools for a wide range of sandwich variations. From crispy bacon to melting cheese, these presses can handle it all.

Within the market, there is a clear division between entry-level and premium heavy duty sandwich presses. Entry-level models are designed for smaller operations that may not require the high capacity or advanced features of their premium counterparts. However, as the market has matured, even entry-level presses have seen significant advancements in terms of build quality and performance.

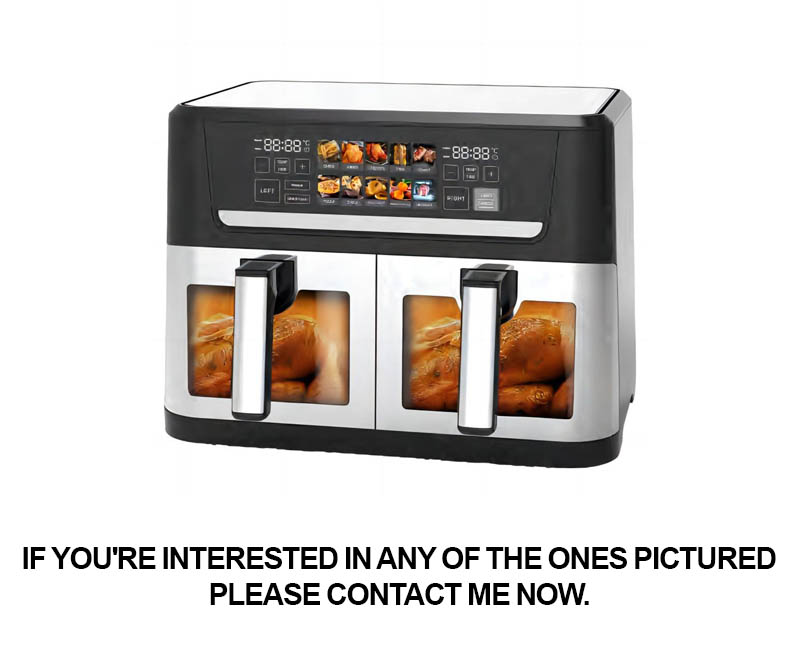

On the other side of the spectrum, premium heavy duty sandwich presses are the pinnacle of innovation. These machines often come with features like programmable settings, digital temperature controls, and non-stick surfaces that make them perfect for high-end restaurants and foodservice establishments that demand excellence in every aspect of their food preparation.

As we navigate through the heavy duty sandwich press market, it’s important to note that not all products are created equal. The market is saturated with various brands, each promising quality and reliability. However, discerning consumers and industry professionals alike are increasingly turning to reputable factories that have established a reputation for producing top-notch sandwich presses.

One such factory that stands out in the industry is known for its commitment to excellence and continuous improvement. This factory has a robust R&D department that constantly explores new materials, manufacturing techniques, and design concepts to stay ahead of the curve. Their presses are not just a product; they are a testament to their dedication to quality and innovation.

Another key factor in the heavy duty sandwich press market is the focus on safety. With the potential for high heat and pressure, these machines must be designed with the utmost safety in mind. Factories that prioritize safety in their manufacturing process ensure that operators can use the presses with confidence, knowing that they are protected from potential hazards.

The heavy duty sandwich press market is also influenced by global trends. As the world becomes more health-conscious, there is a growing demand for healthier sandwich options. This shift has led to the development of presses that can accommodate a variety of ingredients, from whole-grain bread to lean proteins and fresh vegetables, allowing for the creation of nutritious, wholesome sandwiches.

In conclusion, the heavy duty sandwich press market is a dynamic and competitive space that is constantly evolving. With the rise of casual dining, the demand for these robust machines has surged, and factories are stepping up to meet the challenge. Whether it’s through innovation, quality, safety, or a focus on health, these factories are setting the standard for the future of sandwich preparation.

The sandwich press, once a humble kitchen gadget, has undergone a remarkable transformation from a simple home appliance to a robust, industrial-grade tool. This evolution reflects the dynamic nature of technology and the changing demands of consumers.

Early sandwich presses were straightforward devices, designed with a singular purpose: to toast two slices of bread between hot plates, creating the perfect sandwich. These presses were often made of heavy cast iron or aluminum, ensuring durability and even heat distribution. They became a staple in many households, symbolizing the rise of convenience cooking and the American love affair with the sandwich.

As the culinary world expanded, so did the variety of sandwiches. The need for a more uniform and crispy result led to the introduction of spring-loaded models, which provided better pressure and consistency. These advancements in design catered to home cooks looking to elevate their sandwich-making skills.

The commercial sector soon recognized the potential of the sandwich press. Initially, restaurants and delis used them to speed up the service of simple ham and cheese sandwiches. However, as gourmet sandwiches gained popularity, so did the demand for more versatile presses. This demand pushed manufacturers to create units capable of handling thicker fillings, more intricate designs, and even brioche or baguettes.

The transition to industrial-strength sandwich presses was marked by several key developments. The introduction of adjustable pressure mechanisms allowed operators to customize the toasting intensity for different types of bread and fillings. Additionally, non-stick coatings and high-quality materials made the presses more hygienic and easier to clean, crucial for maintaining a busy kitchen.

Industrial sandwich presses are not just for bread, either. The versatility of these machines has expanded to include paninis, melts, and even stuffed pastries. Some models now come with built-in grills or sear plates, allowing for a wide range of food preparation options.

In terms of size, industrial presses have grown to accommodate large batches, ensuring efficient service during peak hours. The increased capacity has also allowed for the production of sandwich presses suitable for countertop use, which can be found in convenience stores and food trucks.

As technology has advanced, so too has the control over the cooking process. Digital control panels allow for precise temperature settings and cooking times, ensuring consistency in the final product. This level of control is particularly important in the foodservice industry, where consistency is key to customer satisfaction.

The evolution of sandwich presses has not only been about size and power; it has also been about adaptability. Many presses now come with removable parts and interchangeable components, making them suitable for different types of cooking environments, from fine dining to fast-food outlets.

Moreover, the sustainability movement has influenced the design of new sandwich presses. Eco-friendly materials and energy-saving features are becoming standard, as manufacturers respond to the growing demand for environmentally responsible products.

In conclusion, the sandwich press has journeyed from a simple kitchen device to a versatile and powerful tool used in both residential and commercial settings. This evolution is a testament to the ever-changing landscape of foodservice and the innovative spirit of the manufacturing industry. The heavy-duty sandwich press has become more than a means to an end; it’s a symbol of the convenience and creativity that cooking has come to represent.

Heavy duty sandwich presses have become a staple in various industries, and the role of factories specializing in their production is pivotal. These factories are the backbone of the market, driving innovation, meeting demand, and ensuring quality.

These factories are not just manufacturing sites; they are hubs of engineering expertise. They take raw materials like metal, plastic, and rubber, and transform them into robust, reliable, and efficient sandwich presses. Each press is designed to withstand the rigors of commercial use, whether it’s in a busy restaurant kitchen, a fast-food outlet, or a food service establishment.

The precision required in the manufacturing process is remarkable. Heavy duty sandwich presses must be able to apply consistent pressure, ensuring that each sandwich is cooked to perfection with minimal variation. Factories achieve this through meticulous attention to detail in every stage of production, from design and prototyping to assembly and quality control.

Innovation is at the heart of what these factories do. They are constantly evolving their designs to incorporate new features that enhance the performance of the sandwich presses. This could be anything from improved heat distribution to ergonomic handles that reduce the strain on the operator. The ability to innovate is crucial for these factories to stay competitive in a market that is always seeking the next big thing.

Supply chain management is another critical function of heavy duty sandwich press factories. They must ensure a steady supply of components and materials to maintain production schedules. This requires a network of suppliers who can deliver high-quality inputs without delays. The complexity of this network is often underestimated, as it involves logistics, inventory management, and risk mitigation.

These factories also play a key role in after-sales service. They understand that a sandwich press is an investment, and they are committed to ensuring that it continues to perform well over its lifetime. This includes providing customer support, offering repair services, and even providing training on how to use the equipment properly. The level of service offered can significantly impact customer satisfaction and brand loyalty.

Quality control is non-negotiable in the heavy duty sandwich press industry. Factories adhere to strict standards to ensure that each unit meets the required specifications. This involves rigorous testing at various stages of the production process, from individual components to the fully assembled press. The goal is to deliver a product that is not only durable but also meets the highest safety and performance standards.

Moreover, these factories often contribute to the sustainability efforts within the industry. By using eco-friendly materials and practices, they reduce their environmental footprint. This commitment to sustainability is not just a corporate responsibility; it’s also a reflection of the broader market’s increasing demand for green products.

Innovation, efficiency, and quality are the cornerstones of success for heavy duty sandwich press factories. They are responsible for creating products that streamline the cooking process, improve food consistency, and enhance the customer experience. As the demand for high-quality, heavy-duty sandwich presses grows, these factories continue to expand their capabilities and explore new technologies to stay ahead of the curve.

The integration of advanced manufacturing technologies, such as robotics and automation, has also transformed the operations of these factories. This not only increases production speed but also improves accuracy and reduces the likelihood of human error. The result is a more streamlined process that can produce larger quantities of sandwich presses while maintaining the same level of quality.

In the end, heavy duty sandwich press factories are not just about manufacturing hardware. They are about creating solutions that address the needs of a dynamic market. From the design and engineering phase to the final product, these factories are committed to delivering excellence. Their role in the industry is multifaceted, encompassing everything from manufacturing to customer satisfaction and environmental responsibility.

In the realm of sandwich presses, innovation has become a cornerstone for leading factories striving to stay ahead in a competitive market. These factories are not just manufacturing appliances; they are crafting solutions that cater to the evolving demands of both commercial and domestic users. Here’s a glimpse into the groundbreaking design and functionality that these factories are pushing forward.

The integration of smart technology has revolutionized the sandwich press landscape. Modern presses now come equipped with digital controls that allow for precise temperature regulation, ensuring that every sandwich is cooked to perfection. Factories are introducing touchscreens that not only provide an intuitive user interface but also offer customizable settings, making it possible for operators to tailor the cooking process to specific types of bread or fillings.

One of the standout innovations is the introduction of variable pressure systems. These systems allow users to adjust the pressure applied during the cooking process, which is crucial for achieving the desired texture and crispiness in the sandwich. Leading factories are fine-tuning these systems to ensure that they are both durable and responsive, accommodating everything from delicate brioche to hearty focaccia.

The design of sandwich presses has also seen a shift towards user convenience. Modern models feature non-slip bases and ergonomic handles, making them safer and easier to use. Factories are now incorporating features like removable drip trays and easy-to-clean surfaces, which not only enhance the hygiene of the appliance but also simplify the cleaning process for the end-user.

Safety has always been a priority in kitchen appliances, and leading factories are taking it to new heights. Advanced safety features such as automatic shut-off mechanisms have become standard in many models. These mechanisms detect when the press is left unattended and turns off the heat to prevent any potential hazards. Additionally, some models come with thermal protection to safeguard against overheating.

In the realm of functionality, there’s a growing trend towards versatility. Factories are now producing sandwich presses that can not only handle the classic two-layered sandwich but also cater to the burgeoning popularity of open-faced sandwiches and even gourmet sliders. The ability to adjust the press to different sandwich sizes and shapes is a game-changer for cafes and delis looking to offer a diverse menu.

Customization is another area where innovation is flourishing. Some factories are offering sandwich presses with interchangeable plates, allowing users to switch between flat-top and grill-style cooking. This versatility means that the same machine can be used to toast bread, sear vegetables, or even cook eggs—multiplying its utility in a commercial kitchen.

Energy efficiency is also a key focus for leading factories. As environmental concerns grow, so does the demand for appliances that consume less energy. These factories are developing sandwich presses with energy-saving modes and LED indicators that reduce power consumption without compromising on performance.

The design of sandwich presses has also embraced sustainability. Materials used in construction are becoming more eco-friendly, with a move towards recycled plastics and sustainable metals. Some presses are even designed to be fully recyclable at the end of their life, minimizing their environmental footprint.

In terms of aesthetic, leading factories are paying close attention to the look of their products. Sandwich presses are now available in a range of colors and finishes, from sleek stainless steel to rustic wood tones, allowing them to fit seamlessly into any kitchen setting, from the bustling streets of a city to the cozy confines of a home kitchen.

Finally, the rise of social media and food culture has influenced the design and functionality of sandwich presses. Factories are now incorporating features that make it easier for users to share their culinary creations, such as built-in photo spots and shareable recipes on the digital interfaces.

The innovations from leading sandwich press factories are not just limited to the products themselves; they extend to the entire ecosystem surrounding them. From customer service and warranty programs to educational content and community engagement, these factories are creating a comprehensive experience for users who value quality, innovation, and functionality in their kitchen appliances.

The heavy duty sandwich press sector is constantly evolving, with new trends shaping the market landscape. Here’s a look at some of the current hotspots in this dynamic industry:

Eco-Friendly Materials – With environmental concerns at the forefront, leading factories are now focusing on sandwich presses made from sustainable and recyclable materials. This shift not only appeals to eco-conscious consumers but also aligns with global efforts to reduce carbon footprints.

Smart Technology Integration – The integration of smart technology has become a major trend in the heavy duty sandwich press sector. Factories are now incorporating features like digital temperature controls, Bluetooth connectivity for remote monitoring, and even AI-driven predictive maintenance to enhance user experience and efficiency.

Versatility in Design – Sandwich presses are no longer just for making sandwiches. Innovations in design have expanded their functionality, with some models now capable of grilling, toasting, and even flipping food items. This versatility is attracting a wider audience beyond the traditional sandwich enthusiasts.

Customization and Personalization – Factories are embracing customization as a key trend. From adjustable pressure settings to interchangeable plates for different types of food, consumers are now able to tailor their sandwich presses to their specific preferences and dietary needs.

Health and Wellness Focus – As the health and wellness movement gains momentum, there’s a growing demand for sandwich presses that can accommodate healthier options. This includes models with non-stick surfaces that reduce the need for oil, and those that can handle high-heat cooking to preserve the nutritional value of ingredients.

Sustainability and Energy Efficiency – The heavy duty sandwich press sector is increasingly focusing on energy efficiency. New models are being designed with energy-saving features, such as automatic shut-off mechanisms and lower power consumption, which are both cost-effective and environmentally friendly.

Portability and Compactness – In response to the need for convenience, factories are producing lighter and more compact sandwich presses. These portable units are perfect for campers, students, or anyone who wants to enjoy a freshly made sandwich on the go without the bulk of traditional kitchen appliances.

Safety Features – Safety is a top priority in the design of heavy duty sandwich presses. Recent innovations include non-slip bases, child safety locks, and cool-touch handles to prevent accidental burns. These features are becoming standard in the industry, reassuring consumers of the safety of their appliances.

Globalization of Trends – Trends in the heavy duty sandwich press sector are becoming more globalized, with factories taking inspiration from international cuisine. This has led to the development of sandwich presses that can handle a variety of international recipes, from Asian-style buns to European open-face sandwiches.

Marketing and Branding – The way sandwich presses are marketed and branded is also evolving. Factories are using social media influencers and content marketing to reach a broader audience. They’re emphasizing the ease of use, the quality of materials, and the versatility of their products to stand out in a crowded market.

Customer Feedback and Continuous Improvement – Factories are placing a greater emphasis on customer feedback, using it to drive continuous improvement. This customer-centric approach ensures that the latest models are not only innovative but also meet the real-world needs and expectations of consumers.

Certifications and Standards – With the rise in consumer awareness about product safety and quality, there’s a growing trend towards obtaining certifications and adhering to international standards. Factories that can demonstrate compliance with these standards are gaining trust and market share.

These trends highlight the dynamic nature of the heavy duty sandwich press sector, with manufacturers constantly seeking to innovate and meet the changing demands of consumers. As the industry continues to evolve, it’s likely that we’ll see even more exciting developments in the future.

In the realm of heavy-duty sandwich press production, technology has not only streamlined the manufacturing process but has also revolutionized the way these appliances are designed and operated. The integration of cutting-edge innovations has led to a surge in efficiency, precision, and user experience. Let’s delve into the impact of technology on this sector.

Precision Engineering and Material ScienceModern heavy-duty sandwich presses rely heavily on precision engineering and material science. Advanced machining techniques allow for the creation of intricate components that are both durable and precise. High-grade metals like stainless steel, aluminum, and titanium are favored for their strength and resistance to heat, ensuring that the sandwich presses can withstand heavy use without compromising on quality.

Automated Assembly LinesThe advent of automated assembly lines has transformed the production of heavy-duty sandwich presses. Robots and specialized machinery work in harmony to assemble components with extreme accuracy, reducing the potential for human error and increasing output. These lines are capable of handling a high volume of production, ensuring that the market’s demand is met efficiently.

Smart Sensors and Control SystemsIntegrating smart sensors into the design of heavy-duty sandwich presses has allowed for real-time monitoring of performance. These sensors can detect temperature, pressure, and even the amount of force being applied, ensuring consistent results with every press. Control systems have evolved to become more intuitive, with user interfaces that are easy to navigate, even for those not technically inclined.

Energy Efficiency and SustainabilityTechnology has played a pivotal role in making heavy-duty sandwich press production more energy-efficient and sustainable. Advanced insulation materials reduce heat loss, leading to lower energy consumption during the pressing process. Moreover, some presses now come with energy-saving modes that can be activated during periods of lower usage, further cutting down on operational costs.

Customization and PersonalizationCustomization has become a key trend in the heavy-duty sandwich press industry. With the help of technology, factories can now produce presses that are tailored to specific customer needs. Whether it’s adjusting the pressure for different types of sandwiches or integrating additional features like non-stick surfaces or digital displays, technology allows for a high degree of personalization.

Durability and LongevityOne of the most significant impacts of technology on heavy-duty sandwich press production is the increase in durability and longevity. By using high-quality materials and advanced manufacturing techniques, presses are now designed to last longer and require less frequent maintenance. This not only saves costs for businesses but also enhances the user experience by providing reliable and consistent performance over time.

Quality Assurance and SafetyQuality control in heavy-duty sandwich press production has been elevated through the use of technology. Automated testing systems can simulate real-world conditions to ensure that every press meets the highest safety standards. These tests include checking for structural integrity, temperature distribution, and compliance with health and safety regulations.

Integration with Smart Kitchen AppliancesThe integration of heavy-duty sandwich presses with smart kitchen appliances is another technological advancement. These presses can now be connected to home automation systems, allowing users to monitor and control their presses remotely. This integration opens up new possibilities for creating smart kitchen environments that are both convenient and efficient.

Environmental ConsiderationsLastly, technology has enabled heavy-duty sandwich press factories to be more environmentally conscious. By reducing waste, optimizing resource usage, and developing eco-friendly manufacturing processes, these factories are contributing to a greener future. Innovations like solar power for factory operations and recycling programs for used materials are becoming increasingly common.

In summary, the impact of technology on heavy-duty sandwich press production is profound. From enhancing precision and efficiency to improving safety and sustainability, technological advancements are reshaping the industry, offering new opportunities and challenges for both manufacturers and consumers alike.

In the realm of heavy-duty sandwich press production, several factories have carved out a niche for themselves with remarkable success stories. These case studies highlight not just the products they manufacture, but also the innovative approaches and strategies that have propelled them to the forefront of the industry.

One such factory, known for its precision engineering, has seen a surge in demand for its high-capacity sandwich presses. Their success can be attributed to a combination of factors, including a relentless pursuit of quality and a keen understanding of market needs. Their presses are not only robust and durable but also equipped with features that cater to the specific requirements of commercial kitchens.

The factory’s R&D team has developed a unique heat distribution system that ensures even cooking across the sandwich, a crucial aspect for maintaining consistency in the final product. This innovation has not only won them accolades but also a loyal customer base that values reliability and performance.

Another standout case is a factory that has embraced sustainability in its production process. They have integrated eco-friendly materials and energy-efficient technologies into their sandwich presses, making them a favorite among eco-conscious businesses. Their commitment to reducing their carbon footprint has not only set them apart from competitors but has also opened up new markets, particularly in Europe and North America.

This factory’s success lies in its ability to adapt to changing trends. They have introduced a range of sandwich presses that are not only versatile but also customizable, allowing customers to tailor the machines to their specific menu items. This flexibility has made them a go-to choice for fast-food chains and gourmet sandwich shops alike.

A third factory has made waves with its integration of smart technology into their sandwich presses. By incorporating IoT (Internet of Things) capabilities, these presses can be remotely monitored and controlled, offering convenience and efficiency to busy chefs. The factory’s smart sandwich presses have become a hit in the tech-savvy foodservice industry, where data-driven decision-making is becoming increasingly important.

One of the most notable success stories comes from a factory that has mastered the art of mass customization. They have developed a system that allows customers to choose from a variety of components and features to create a sandwich press that perfectly fits their needs. This level of personalization has attracted a diverse clientele, from small local cafes to large-scale food production facilities.

In another instance, a factory has focused on the health and safety of its employees and customers. They have invested in advanced safety features for their sandwich presses, such as automatic shut-off systems and ergonomic designs. This commitment to safety has not only improved their reputation but has also led to a reduction in workplace accidents and increased productivity.

A factory specializing in commercial-grade sandwich presses has also seen success by offering comprehensive training and support to their clients. They understand that the effectiveness of their machines is as much about the knowledge of the operators as it is about the quality of the product. Their training programs have helped countless businesses maximize the potential of their sandwich presses, leading to increased sales and customer satisfaction.

One of the most innovative factories has taken the concept of a sandwich press to new heights by introducing a line of presses that can handle a variety of food items, not just sandwiches. Their versatile machines can be used for grilling, toasting, and even flattening, making them indispensable in a wide range of culinary applications.

These case studies from heavy-duty sandwich press factories demonstrate the power of innovation, customer focus, and a commitment to excellence. From cutting-edge technology to sustainable practices and personalized service, these factories have shown that success in the industry is not just about producing a quality product—it’s about understanding and meeting the evolving needs of the market.

In the realm of heavy-duty sandwich presses, the industry faces a unique set of challenges and opportunities that shape its trajectory. From adapting to evolving consumer demands to navigating the complexities of global supply chains, here’s an insight into the multifaceted world of the heavy-duty sandwich press industry.

The rise of health-conscious consumers has led to a surge in demand for high-quality, fresh sandwiches. This shift has pushed manufacturers to innovate in their products, focusing on hygienic designs and efficient heating elements. Factories must balance these demands with the need for robust construction to withstand the rigorous use expected in commercial settings.

Moreover, the industry is witnessing a growing trend towards customization. Businesses are looking for sandwich presses that can cater to their specific needs, whether it’s a unique shape, size, or even a custom logo. Factories that can offer this level of personalization are gaining a competitive edge, as they cater to the unique branding desires of their clients.

The integration of smart technology has also emerged as a significant opportunity. With the ability to monitor and control the cooking process remotely, sandwich presses equipped with IoT (Internet of Things) capabilities are becoming increasingly popular. This not only enhances efficiency but also allows for predictive maintenance, reducing downtime and extending the lifespan of the equipment.

On the flip side, the industry faces challenges related to material costs and sustainability. As the demand for high-quality materials continues to rise, so does the cost of production. Factories must find ways to manage these expenses without compromising on the durability and performance of their products.

Energy efficiency is another challenge that cannot be overlooked. With environmental concerns at the forefront, heavy-duty sandwich press manufacturers are under pressure to develop more energy-efficient models. This push for sustainability requires not only technological advancements but also a reevaluation of manufacturing processes.

The global supply chain disruptions have also posed a significant challenge. Factories rely on a complex network of suppliers for components, and any disruption can lead to delays and increased costs. Adapting to just-in-time manufacturing and diversifying supplier networks have become crucial strategies for survival.

Despite these challenges, there are numerous opportunities in the heavy-duty sandwich press industry. The rise of food trucks and pop-up restaurants, for example, has created a niche market for portable and versatile sandwich presses. These mobile kitchens demand compact, durable, and easy-to-use equipment, offering a new avenue for growth.

The integration of eco-friendly materials is another opportunity. As consumers become more environmentally conscious, there’s a growing market for products that are not only functional but also sustainable. Factories that can offer a greener alternative without sacrificing performance are likely to attract environmentally conscious buyers.

Additionally, the emergence of subscription-based services for equipment maintenance and repairs presents a unique opportunity. By offering ongoing support and service, factories can establish long-term relationships with their customers, ensuring repeat business and fostering brand loyalty.

Furthermore, the industry can capitalize on the increasing demand for international trade. As the global foodservice industry continues to expand, there’s a significant opportunity for heavy-duty sandwich press manufacturers to export their products to new markets. This expansion can lead to increased revenue and a broader customer base.

Lastly, the industry must adapt to the changing landscape of labor. With the rise of automation and robotics, there’s a potential for factories to streamline their production processes, reducing labor costs and increasing output. However, this shift also requires investment in training and technology, which can be a barrier for some manufacturers.

In conclusion, the heavy-duty sandwich press industry is ripe with opportunities and challenges. From the need for innovation and customization to the pressures of sustainability and global supply chain complexities, factories must navigate these waters with strategic foresight and agility. By embracing these opportunities and addressing the challenges head-on, the industry can continue to thrive and meet the evolving demands of the market.

In the realm of heavy-duty sandwich press manufacturing, the significance of quality control cannot be overstated. It’s the backbone that ensures the longevity and reliability of these robust appliances. Let’s delve into the various aspects that underscore the importance of stringent quality control measures.

Precision Engineering Ensures DurabilityEach component of a heavy-duty sandwich press must be meticulously crafted to withstand the rigorous demands of commercial kitchens. Precision engineering guarantees that the materials and parts are of the highest quality, minimizing the risk of premature wear and tear. From the durable stainless steel used in the press plates to the robust springs and hinges, every detail contributes to the press’s ability to maintain consistent performance over time.

Regulatory Compliance and Safety StandardsThe heavy-duty sandwich press industry is subject to a myriad of safety and regulatory standards. Adhering to these is not just a legal requirement but also a testament to a factory’s commitment to excellence. Quality control ensures that every sandwich press meets these stringent criteria, including electrical safety, material integrity, and fire resistance. This not only protects users but also fosters trust in the brand.

Customization and Customer SatisfactionHeavy-duty sandwich presses are often tailored to meet the specific needs of different businesses. Quality control plays a pivotal role in ensuring that these customizations are executed flawlessly. From precise adjustments to the press mechanism to the integration of unique features, each aspect is scrutinized to guarantee customer satisfaction and the seamless operation of the press.

Cost-Effectiveness Through EfficiencyEfficient quality control processes can lead to significant cost savings for heavy-duty sandwich press manufacturers. By detecting and rectifying defects early in the production cycle, companies can avoid costly recalls or repairs later on. This proactive approach to quality ensures that products are delivered to customers in optimal condition, reducing the long-term expenses associated with product failures.

Enhanced Product Life CycleA heavy-duty sandwich press is a substantial investment for any commercial kitchen. Quality control measures extend the product’s life cycle by preventing malfunctions and breakdowns. Regular maintenance, facilitated by the reliability of a well-constructed sandwich press, reduces downtime and the need for frequent replacements. This, in turn, enhances the overall value of the product for the end-user.

Innovation and Continuous ImprovementThe pursuit of quality in heavy-duty sandwich press manufacturing fosters an environment of innovation. Factories that prioritize quality control are more likely to invest in research and development to improve their products. This continuous improvement can lead to new features, more efficient designs, and even the creation of entirely new products that cater to evolving market demands.

Brand Reputation and Customer LoyaltyThe reputation of a heavy-duty sandwich press manufacturer is closely tied to the quality of its products. Consistently high-quality sandwich presses lead to a positive brand image and customer loyalty. When a restaurant or café can trust that their sandwich press will deliver reliable results, they are more likely to remain a loyal customer, even when considering other options in the market.

MarketIn a competitive industry like heavy-duty sandwich press manufacturing, quality control is a key differentiator. A factory that consistently produces top-notch products will stand out in the marketplace, attracting both new customers and partnerships. This competitive edge can lead to increased market share and a stronger position in the global supply chain.

Environmental ResponsibilityQuality control extends beyond the product itself and into the production process. Factories that prioritize quality often adopt eco-friendly practices, such as reducing waste, using sustainable materials, and minimizing energy consumption. This commitment to environmental responsibility can also enhance the brand’s image and appeal to customers who value eco-conscious businesses.

In conclusion, the importance of quality control in heavy-duty sandwich press manufacturing cannot be overstated. It underpins everything from durability and safety to customer satisfaction and environmental responsibility. By maintaining the highest standards throughout the production process, manufacturers can ensure that their products continue to meet the demands of the industry and exceed the expectations of their customers.

In the ever-evolving landscape of heavy duty sandwich press manufacturing, the future holds a blend of innovation, technological advancements, and strategic industry moves. Factories at the forefront of this sector are not just producing equipment; they are shaping the future of commercial cooking. Here’s a glimpse into what lies ahead for these factories:

The integration of smart technology is set to revolutionize the production process. Factories are investing in automated systems that not only enhance efficiency but also ensure precision in every sandwich press they roll out. This shift towards automation is not just about saving time; it’s about reducing human error and increasing consistency in the final product.

As sustainability becomes a key concern, heavy duty sandwich press factories are exploring eco-friendly materials and energy-efficient designs. The push for greener operations means that the future presses might be lighter, more durable, and easier on the environment. This shift is not just a trend; it’s a necessity in an era where corporate social responsibility is a critical factor in consumer choice.

The customization of sandwich presses is becoming more prevalent. Factories are recognizing that not all kitchens are the same, and the needs of a high-end restaurant differ greatly from those of a busy café. This has led to a surge in tailor-made solutions, where every aspect of the press—from size to pressure settings—can be adjusted to fit specific commercial requirements.

The rise of mobile kitchens and pop-up eateries has opened new markets for heavy duty sandwich presses. Factories are now producing compact, portable models that are just as robust as their larger counterparts. This adaptability to different operational environments is a testament to the industry’s responsiveness to changing market demands.

Globalization has expanded the reach of heavy duty sandwich press factories. As international trade becomes more fluid, these factories are not only catering to local markets but also exporting their products worldwide. This expansion has led to a greater diversity in customer needs, which in turn drives further innovation and design evolution.

The emphasis on safety is intensifying. With the increased awareness of food safety standards, factories are focusing on creating sandwich presses that not only meet but exceed these regulations. This includes incorporating features like anti-jamming mechanisms, temperature control systems, and safety locks to prevent accidents in busy kitchen environments.

Collaborations between heavy duty sandwich press manufacturers and culinary experts are becoming more common. These partnerships are not just about product development; they are about understanding the evolving needs of the foodservice industry. By integrating insights from chefs and kitchen staff, factories are able to create presses that not only perform well but also enhance the overall cooking experience.

The rise of online sales and e-commerce platforms has changed how customers interact with heavy duty sandwich press factories. Now, buyers can browse through a wide range of products, read reviews, and even customize their orders online. This shift has necessitated a digital transformation within factories, with an emphasis on online marketing and customer service.

The future of heavy duty sandwich press factories is also intertwined with the development of new materials. Advances in materials science are leading to the creation of sandwich presses that are not only more durable but also more cost-effective. Lightweight materials, for instance, could reduce shipping costs and energy consumption during use.

Lastly, the industry is poised to benefit from the Internet of Things (IoT). By embedding sensors in sandwich presses, factories can offer predictive maintenance services, ensuring that customers are always using their equipment at peak performance. This level of connectivity and service is likely to become a standard in the near future.

In conclusion, the future of heavy duty sandwich press factories is a dynamic one, marked by technological advancements, market diversification, and an increased focus on customer satisfaction and sustainability. As these factories continue to innovate, they will undoubtedly play a crucial role in shaping the commercial cooking landscape of the future.