The rise of BPA-free substances in juicers has been a tremendous fashion inside the equipment industry, pushed by means of purchaser demand for healthier and environmentally pleasant alternatives. cloth factories specializing in those substances are at the vanguard, improving product protection and durability. manufacturers are leveraging these innovations to differentiate their products, supplying no longer only fitness benefits but also improved aesthetic and practical capabilities. the usage of advanced substances is raising manufacturing charges, but those are offset through extended market fee and the attraction of top rate, eco-aware products. This shift is bolstering global competitiveness for equipment manufacturers, especially within the juicer area.

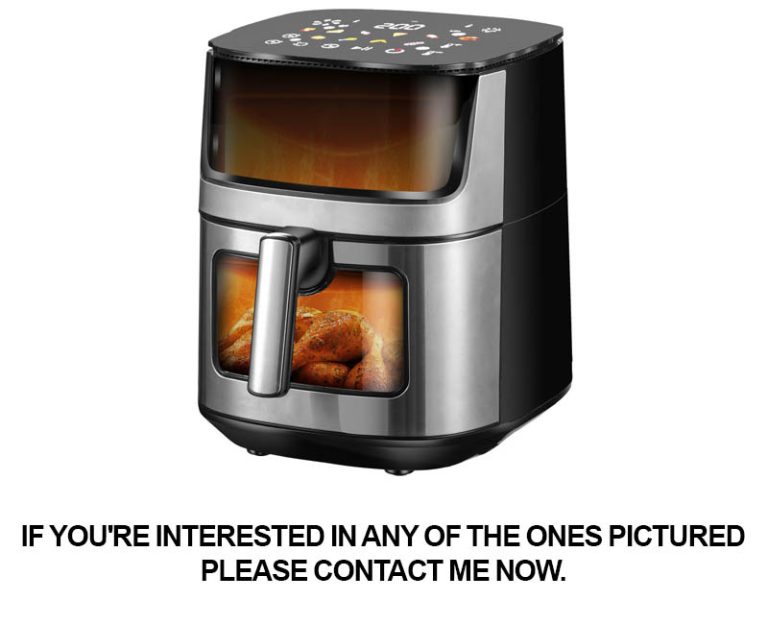

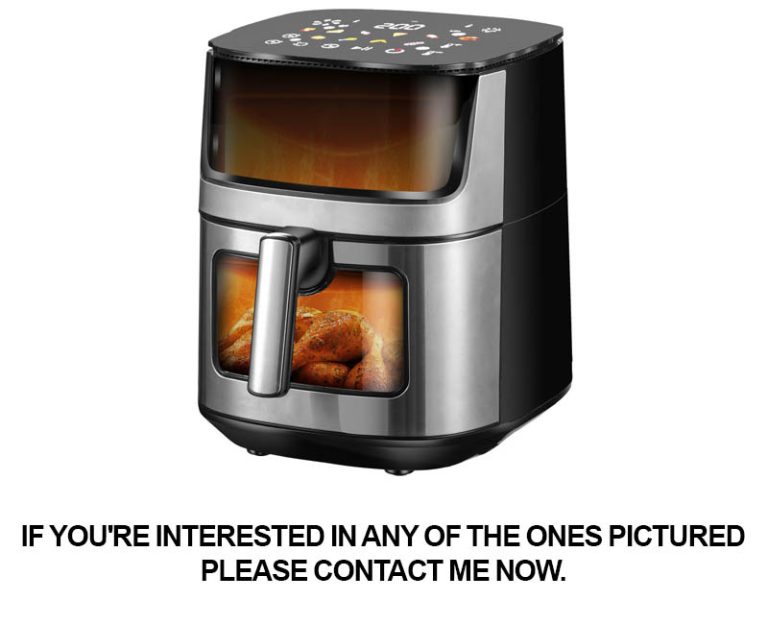

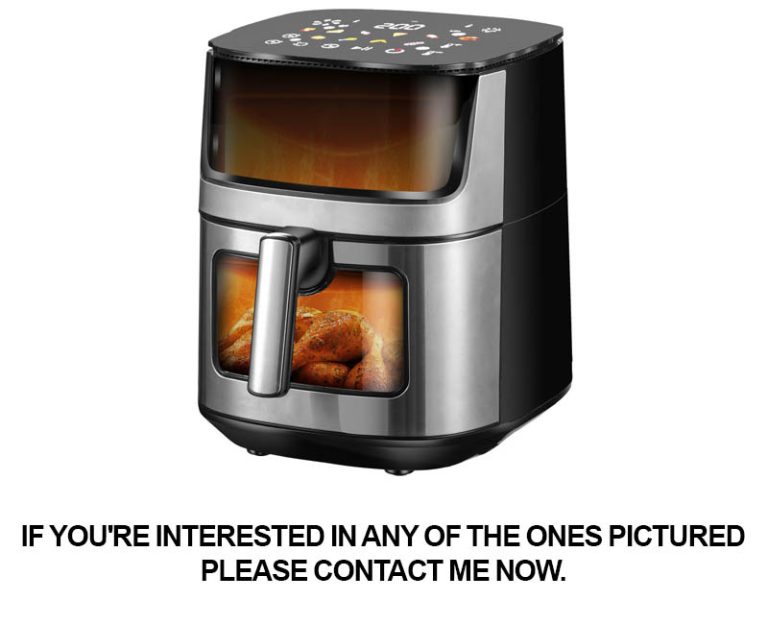

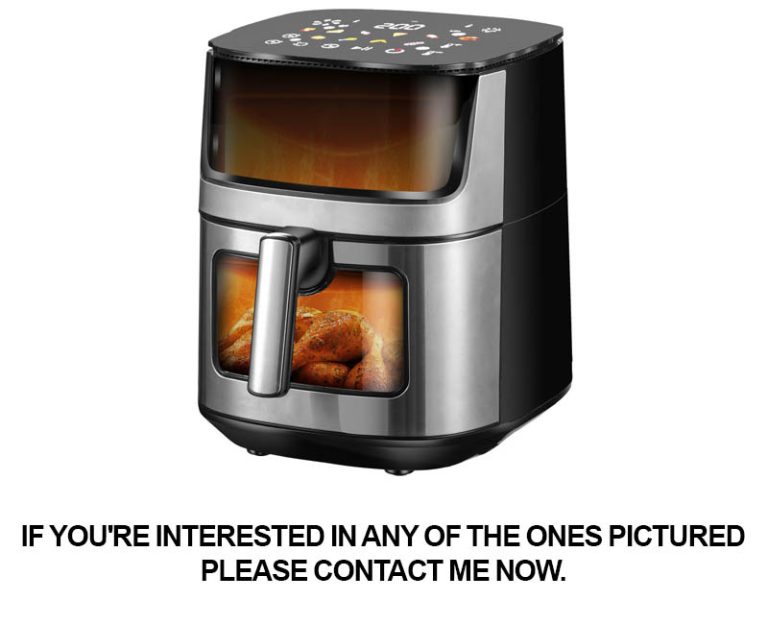

The air fryer OEM market is experiencing rapid increase, pushed by patron call for for healthful cooking alternatives. manufacturers are that specialize in product innovation and smart capabilities, even as emphasizing the importance of warranty substitute to enhance logo reputation and consumer believe. by means of providing clean, green warranty guidelines and short reaction to after-sales problems, OEMs like certain are differentiating themselves, fostering loyalty, and solidifying their aggressive side within the appliance enterprise.

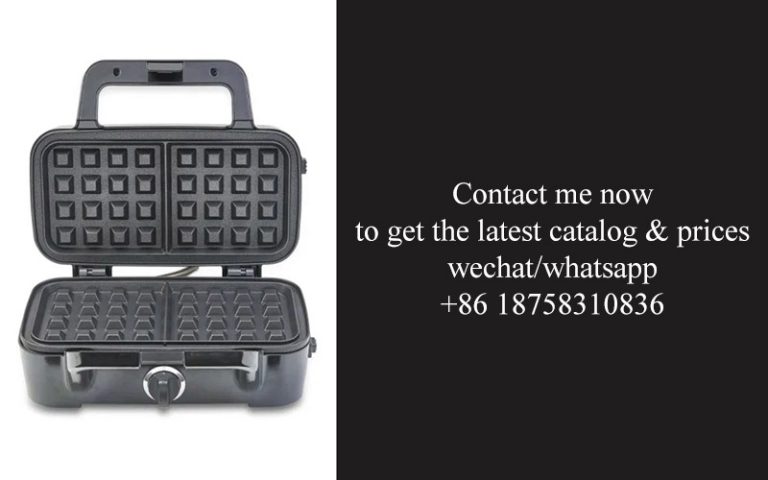

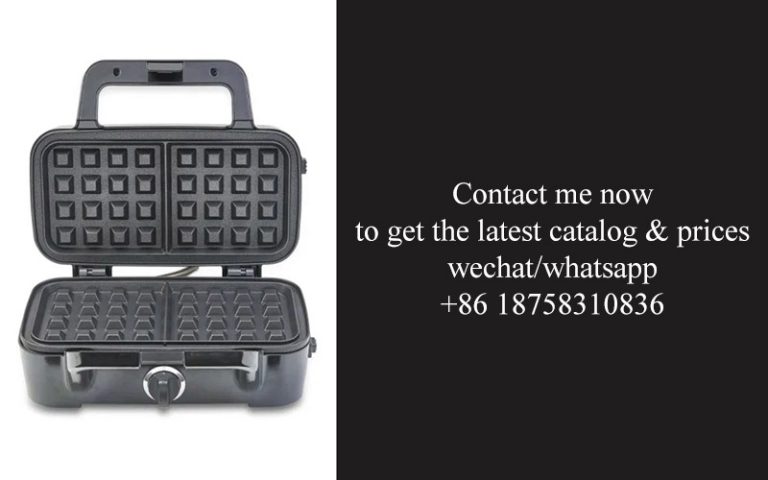

The industrial waffle maker, operating on a 220V standard, has surged in popularity due to its efficiency and versatility, making it a must-have for businesses. Manufacturers are responding by integrating advanced features, such as programmable settings and energy-efficient designs, to enhance performance. These robust machines are not just for breakfast; they offer a range of shapes and sizes, catering to diverse customer preferences. Their durable construction and user-friendly controls make them a cost-effective investment, driving profitability for any establishment looking to offer high-quality waffles.

Navigating the world of air fryer manufacturers can be challenging, but finding a reliable partner is crucial. To ensure quality and alignment with your business values, focus on key factors such as reputation, product quality, and production capabilities. Look for manufacturers offering advanced features, adhering to safety standards, and boasting a range of products. Consider their customer feedback, certifications, and after-sales support. A factory visit can provide a clearer picture of their operations and commitment to excellence. Remember, choosing the right air fryer factory is not just about finding a supplier; it’s about securing a partner for your brand’s success.

The rise of the automated air fryer assembly line has revolutionized the appliance manufacturing industry. This innovative technology has streamlined production processes, allowing manufacturers to produce air fryers at an unprecedented speed and quality. By integrating advanced robotics and AI, these assembly lines efficiently handle tasks from component placement to testing, ensuring each air fryer meets stringent quality standards. This shift has not only boosted efficiency but also paved the way for innovative designs that cater to health-conscious consumers, thereby propelling the air fryer market to new heights.

The rise of the air fryer has transformed the cooking landscape, with OEM air fryers becoming a staple in modern kitchens. Mold making services are pivotal in this evolution, providing manufacturers with the precision and versatility needed to create efficient and innovative air fryers. These specialized molds not only ensure the quality and functionality of the appliances but also allow for cost-effective production and customization. As the demand for healthier cooking solutions continues to grow, manufacturers are leveraging mold making services to develop air fryers that cater to diverse consumer needs, from compact models for urban dwellers to smart, eco-friendly units for health-conscious users. This partnership between mold making and air fryer manufacturing is driving innovation and shaping the future of cooking technology.

In the dynamic kitchen appliance market, the rise of the air fryer has been fueled by consumer demand for healthier cooking alternatives. As manufacturers seek to capitalize on this trend, turnkey UL certified air fryer OEM solutions are becoming increasingly popular. These comprehensive packages offer manufacturers efficiency, cost savings, and compliance with stringent safety standards, such as the respected UL certification. By partnering with OEMs that specialize in air fryer production, manufacturers can focus on brand building and marketing while benefiting from expert design, prototyping, and production processes. This strategic approach not only shortens time to market but also ensures that the final product meets the highest quality and safety standards, enhancing consumer trust and satisfaction.

In the dynamic kitchen appliance market, ETL listed commercial units stand out as a benchmark for safety and quality. These appliances, rigorously tested and certified by Intertek, offer manufacturers a competitive edge and consumers peace of mind. Features like smart technology integration, energy efficiency, and user-friendliness are increasingly being incorporated into these units, transforming the kitchen experience. From refrigerators and dishwashers to ovens and cooktops, ETL listed kitchen appliances are shaping the future of kitchen design and innovation, ensuring manufacturers meet the evolving demands of both consumers and businesses.

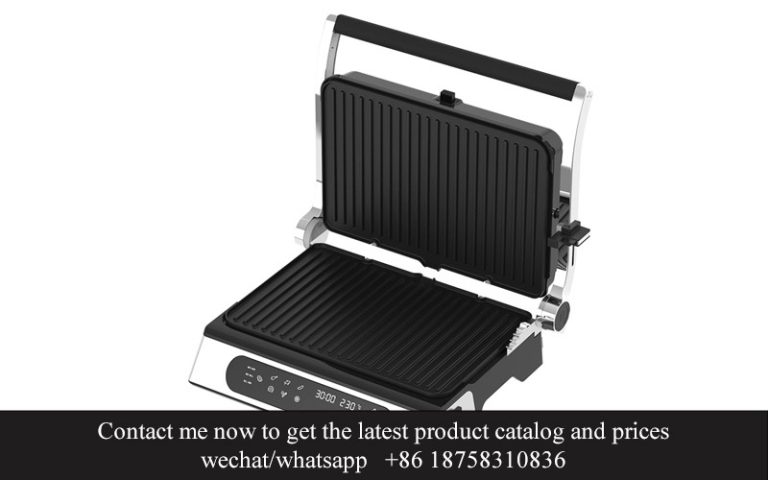

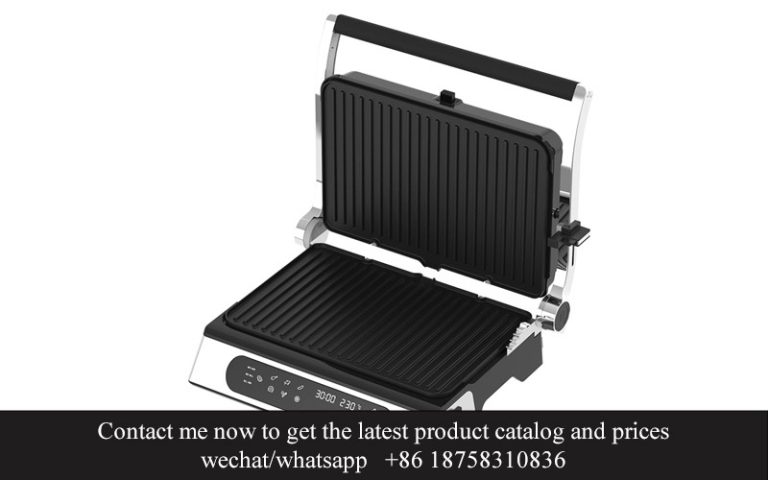

In the realm of grills, in-house mold making has become a pivotal game-changer for manufacturers. This innovative approach empowers companies to create custom molds, enabling the production of diverse, high-quality grill designs. By integrating this process in-house, manufacturers can achieve unparalleled customization, expedite production, and maintain strict quality control. This shift has not only revolutionized the grill market but also enhanced the cooking experience, offering consumers a wider range of cooking appliances that cater to their unique preferences and needs.

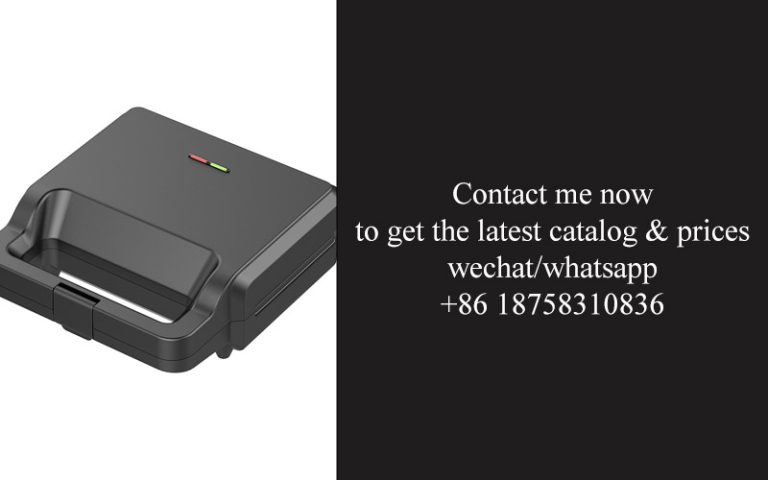

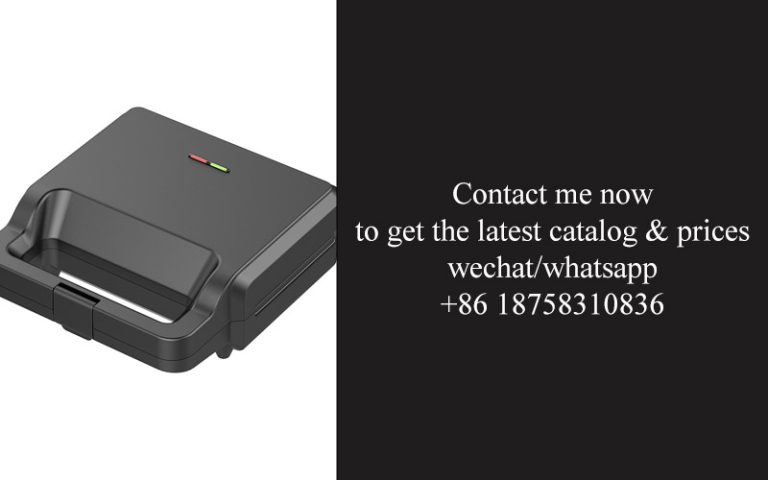

The 120V/240V dual voltage sandwich press has emerged as a versatile kitchen staple, thanks to its adaptability across global voltage standards. OEMs have been pivotal in this revolution, engineering these appliances with cutting-edge technology and user-friendly features. As manufacturers push boundaries, innovations like smart controls, eco-friendly materials, and customizable press plates are becoming the norm. This dual voltage technology not only caters to diverse markets but also underscores the importance of technology in enhancing cooking experiences, making the sandwich press an indispensable appliance for both home chefs and commercial kitchens.