The rise of the automated air fryer assembly line has revolutionized the appliance manufacturing industry. This innovative technology has streamlined production processes, allowing manufacturers to produce air fryers at an unprecedented speed and quality. By integrating advanced robotics and AI, these assembly lines efficiently handle tasks from component placement to testing, ensuring each air fryer meets stringent quality standards. This shift has not only boosted efficiency but also paved the way for innovative designs that cater to health-conscious consumers, thereby propelling the air fryer market to new heights.

In the realm of kitchen appliances, the integrated circuit board factory stands as the silent architect, driving innovation and efficiency. As technology intertwines with daily life, these factories produce microchips that power smart appliances, transforming the kitchen into a hub of innovation. From smart refrigerators that suggest recipes to energy-efficient dishwashers, the integration of advanced ICs enhances cooking experiences. The future of kitchen appliances is bright, with IC board factories at the forefront, shaping a technology-driven culinary landscape that promises convenience, sustainability, and precision in every dish.

In the rapidly evolving healthcare industry, the medical grade stainless steel basket factory stands as a cornerstone of innovation and reliability. These specialized facilities, utilizing advanced technology and precision engineering, produce stainless steel baskets of the highest quality. Known for their durability and resistance to corrosion, these stainless baskets are integral to medical devices and applications, ensuring precision and reliability. The integration of cutting-edge technology, such as robotic welding and CNC machines, has revolutionized production, enabling the creation of intricate and robust stainless steel baskets. As the demand for these baskets continues to grow, the industry’s commitment to excellence in materials, design, and technology ensures that medical grade stainless steel basket factories remain a sure bet for the future of healthcare equipment.

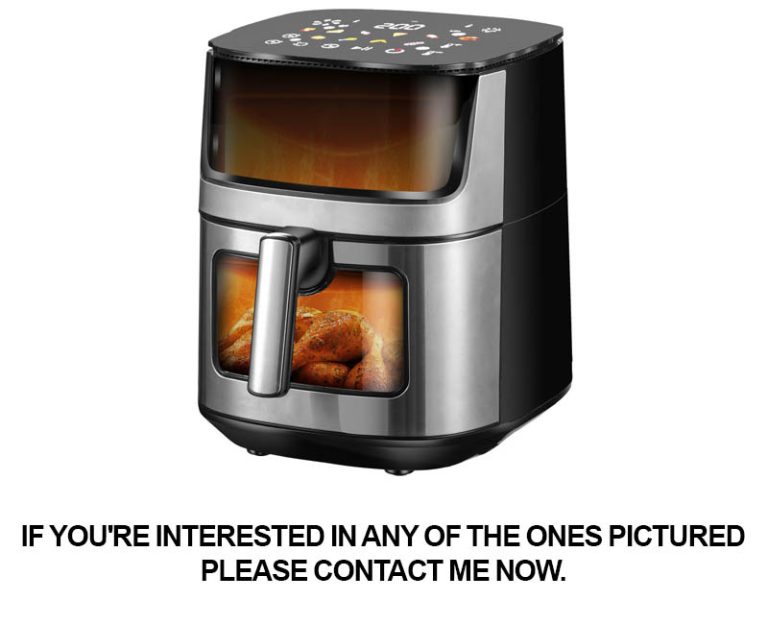

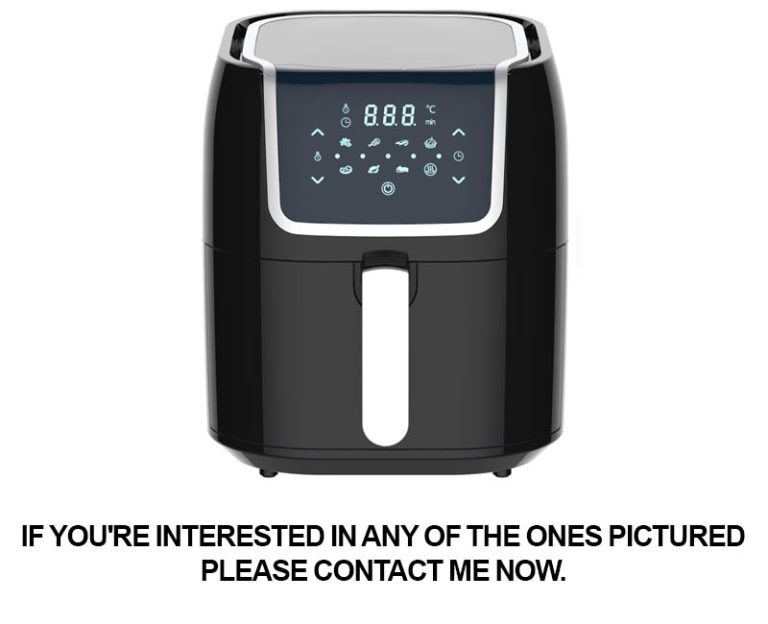

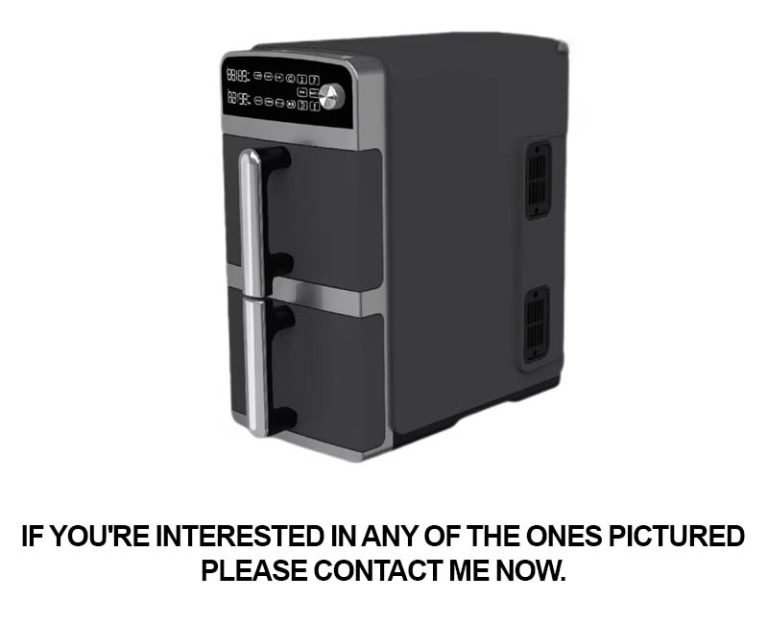

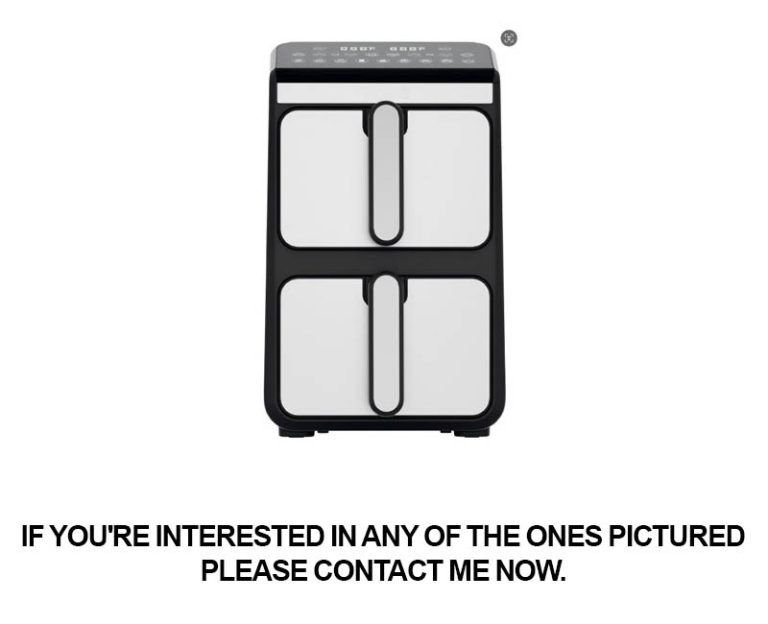

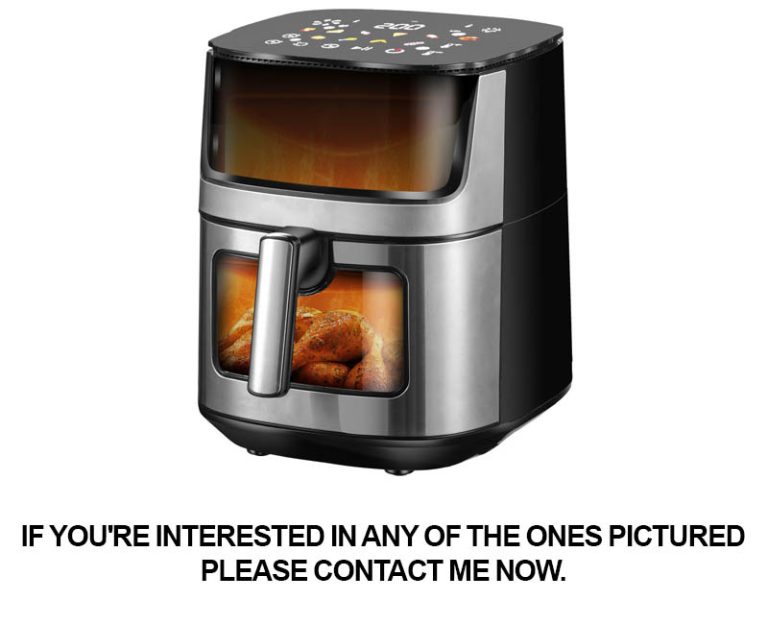

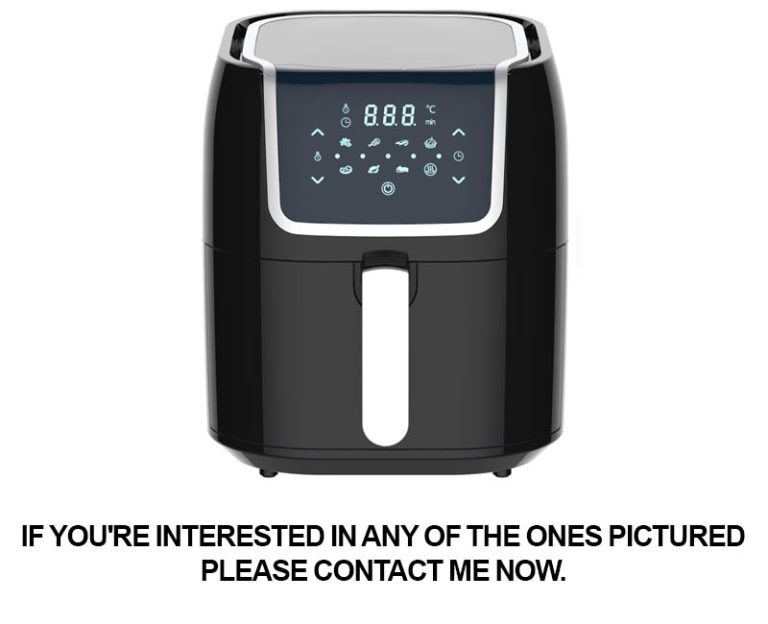

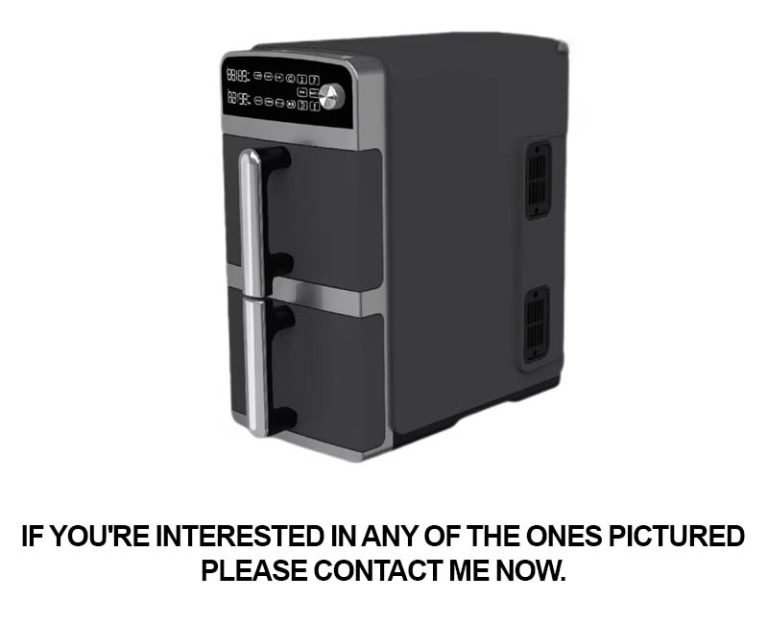

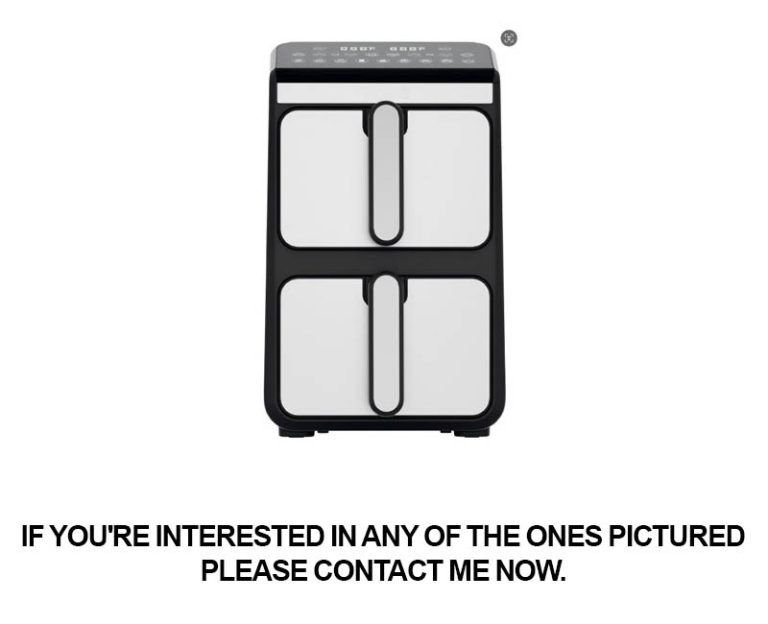

In the commercial kitchen appliance realm, the commercial air fryer factory stands at the forefront of innovative cooking technology. These factories have revolutionized the cooking industry by producing air fryers that offer a healthier alternative to traditional frying methods. By utilizing hot air circulation and minimal oil, these appliances achieve crispy, golden results while significantly reducing fat content. With their rise in popularity, commercial air fryer factories are continuously pushing the boundaries of technology, developing more energy-efficient models, and integrating smart features for remote control and monitoring. This surge in technological advancement not only caters to the growing demand for healthier food options but also enhances the efficiency and versatility of commercial cooking.

In the bustling foodservice industry, the heavy-duty sandwich press factory stands as a cornerstone of innovation and efficiency. These factories, equipped with cutting-edge technology, craft presses that combine robust features with user-friendly design. Key features include adjustable pressure for perfect toasting, digital temperature controls for precision, and non-stick surfaces for easy cleaning. As technology advances, these factories are integrating smart features like IoT connectivity for remote monitoring and predictive maintenance. The result is a versatile tool that streamlines cooking processes, ensuring consistent, high-quality sandwiches across various commercial settings.

In the dynamic kitchen appliances market, integrated metal stamping for sandwich plates is revolutionizing the industry with its high efficiency and precision. This innovative technology is not only enhancing the aesthetic appeal and durability of these plates but also streamlining the manufacturing process. The rise of such advanced techniques signifies a shift towards more efficient and technologically advanced kitchen appliances, catering to a consumer base that values both convenience and functionality.

The 120V/240V dual voltage sandwich press has emerged as a versatile kitchen staple, thanks to its adaptability across global voltage standards. OEMs have been pivotal in this revolution, engineering these appliances with cutting-edge technology and user-friendly features. As manufacturers push boundaries, innovations like smart controls, eco-friendly materials, and customizable press plates are becoming the norm. This dual voltage technology not only caters to diverse markets but also underscores the importance of technology in enhancing cooking experiences, making the sandwich press an indispensable appliance for both home chefs and commercial kitchens.

In the ever-evolving landscape of technology, DDP Hamburg has emerged as a leading OEM supplier in the kitchen appliance industry, renowned for its innovative and efficient solutions. With a deep understanding of market trends and customer needs, the company has become synonymous with quality and reliability, particularly in the European and American markets. DDP Hamburg’s commitment to cutting-edge technology and sustainable practices is evident in its wide range of products, from smart kitchen gadgets to energy-efficient appliances, all designed to enhance the modern kitchen experience.

In the dynamic kitchen appliances market, Lazada and Shopee have emerged as powerful platforms for dropshipping suppliers. These suppliers are driving innovation and convenience, offering a wide range of appliances that cater to evolving consumer needs. With the integration of cutting-edge technology, such as smart connectivity and energy efficiency, these suppliers are not only meeting market demands but also setting new standards in the industry. Their strategic partnerships, efficient supply chains, and seamless customer service ensure that the latest kitchen appliances reach consumers swiftly and reliably, making Lazada and Shopee the go-to destinations for both retailers and buyers.

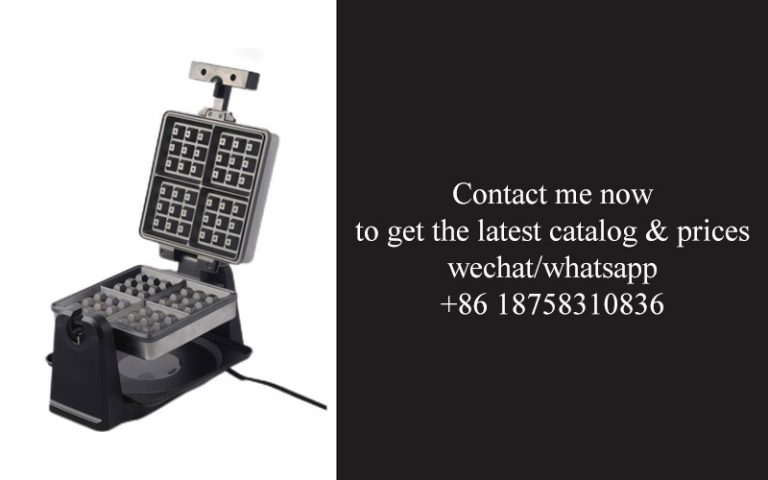

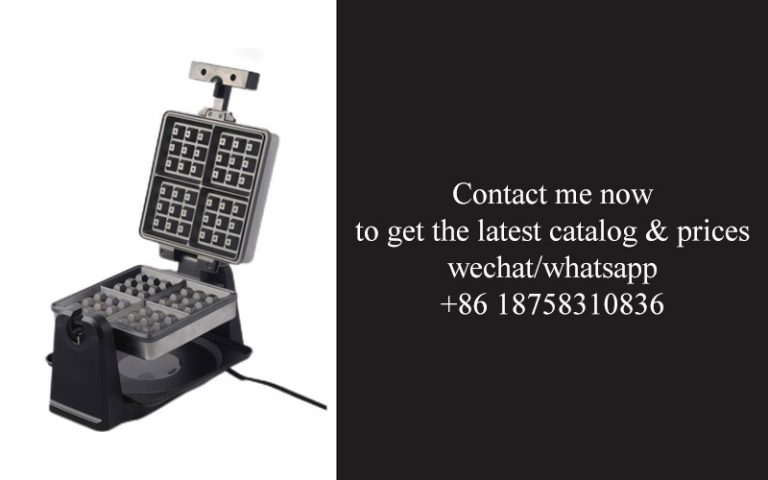

Nestled in the heart of culinary innovation, the waffle maker factory is a haven where tradition meets cutting-edge technology. Here, skilled artisans blend their centuries-old craftsmanship with the latest advancements, ensuring every waffle maker is a sure-to-perfect creation. The factory, a testament to human ingenuity, seamlessly integrates age-old methods with state-of-the-art technology, producing not just appliances, but works of art that bring joy to breakfast tables worldwide.